Hezhen Highlighter long acting luminescent stone color luminous gravel fish tank landscape paving luminescent stone

2025.02.20

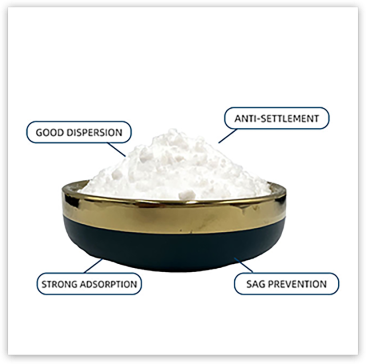

Talc, a naturally occurring mineral, becomes an essential ingredient across a variety of products due to its unique qualities. Recognized for its softness and absorbent properties, talc plays a pivotal role in a range of consumer and industrial products.

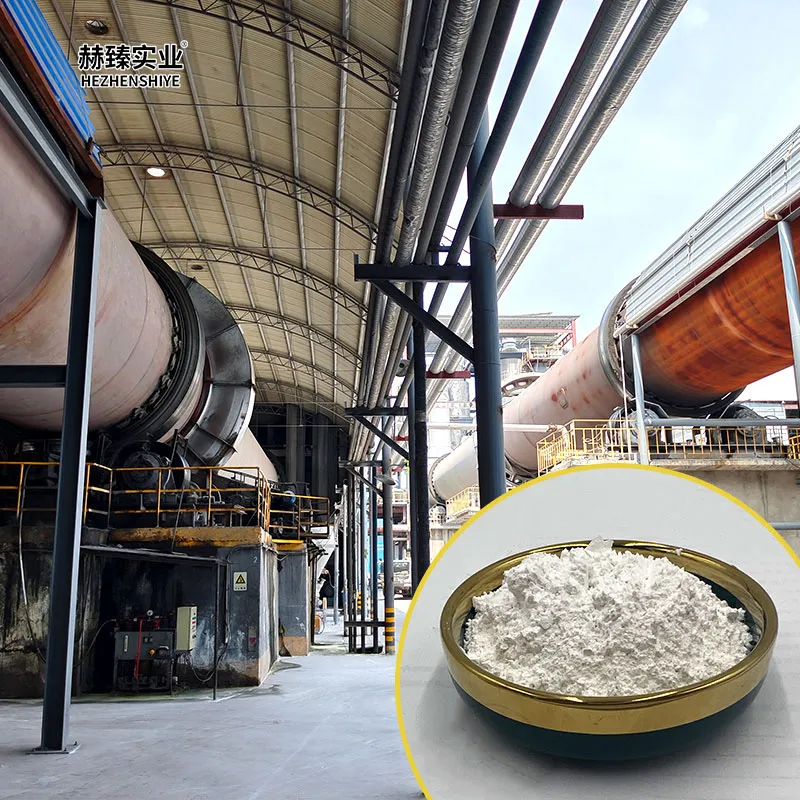

The use of talc is not limited to consumer goods; it also finds a significant place in the industrial sector. Manufacturers depend on talc in the production of ceramics, where it acts as a flux to lower firing temperatures and improve the strength and durability of finished products. Experienced ceramic engineers and manufacturers attest to talc's role in achieving the desired product characteristics essential for both functional and aesthetic applications. In the realm of plastics, talc acts as a reinforcement agent. Automotive and appliance industries heavily rely on talc-filled polymers to enhance the rigidity and heat resistance of plastic components. Those who work in material engineering appreciate talc's capacity to improve the mechanical properties of these materials, thereby extending the lifespan and enhancing the performance of the products in which they are used. Environmental and health organizations underscore the importance of responsible sourcing and processing of talc to maintain its credibility. Transparent practices and third-party certifications assure consumers and industries that the talc used is safe, asbestos-free, and ethically produced. This bolsters trust, ensuring that talc-based products meet stringent safety standards. In conclusion, talc remains an invaluable component across several sectors due to its unique properties and broad applicability. From elevating the quality of personal care and cosmetic products to enhancing industrial processes and materials, talc's diverse capabilities are recognized and relied upon by experts in multiple fields. Its continued relevance is supported by ongoing research and a commitment to safety and quality, affirming its status as an essential and trusted material.

The use of talc is not limited to consumer goods; it also finds a significant place in the industrial sector. Manufacturers depend on talc in the production of ceramics, where it acts as a flux to lower firing temperatures and improve the strength and durability of finished products. Experienced ceramic engineers and manufacturers attest to talc's role in achieving the desired product characteristics essential for both functional and aesthetic applications. In the realm of plastics, talc acts as a reinforcement agent. Automotive and appliance industries heavily rely on talc-filled polymers to enhance the rigidity and heat resistance of plastic components. Those who work in material engineering appreciate talc's capacity to improve the mechanical properties of these materials, thereby extending the lifespan and enhancing the performance of the products in which they are used. Environmental and health organizations underscore the importance of responsible sourcing and processing of talc to maintain its credibility. Transparent practices and third-party certifications assure consumers and industries that the talc used is safe, asbestos-free, and ethically produced. This bolsters trust, ensuring that talc-based products meet stringent safety standards. In conclusion, talc remains an invaluable component across several sectors due to its unique properties and broad applicability. From elevating the quality of personal care and cosmetic products to enhancing industrial processes and materials, talc's diverse capabilities are recognized and relied upon by experts in multiple fields. Its continued relevance is supported by ongoing research and a commitment to safety and quality, affirming its status as an essential and trusted material.