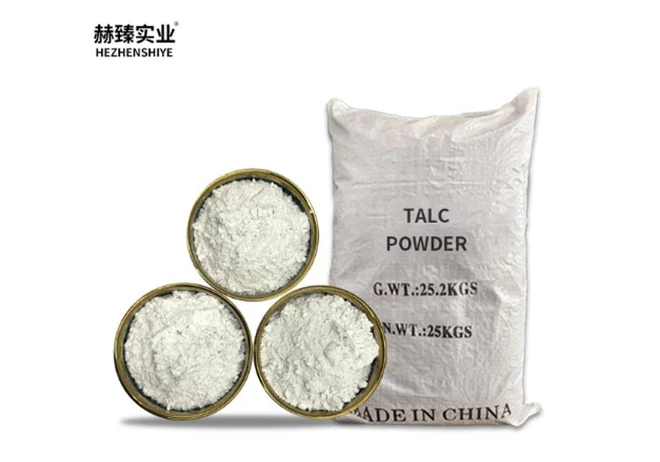

talc powder for rubber

2025.03.03

Talc powder, often considered a crucial component in the rubber industry, enhances the performance and properties of rubber compounds. Its unique characteristics make it indispensable for various applications, and understanding its role is essential for manufacturers aiming to optimize their product quality.

Importantly, talc's compatibility with various chemical compounds makes it a versatile additive. It does not react adversely with other ingredients in the rubber mix, ensuring that the end-product maintains its designed properties and performance. This compatibility underscores talc's role in custom formulations, where precise chemical interactions are imperative for achieving specific material characteristics. From an environmental standpoint, talc powder also contributes positively. It is a naturally occurring mineral and when responsibly sourced, it embodies a renewable aspect desired in modern manufacturing. Responsible talc mining and processing thus supports efforts towards sustainable industrial practices, addressing both environmental and corporate social responsibilities. In terms of industry best practices, leveraging talc powder necessitates an understanding of its grades and specifications, which vary depending on the source. Manufacturers need to select the appropriate grade of talc to match their specific application requirements, ensuring optimal performance. Collaborating with talc suppliers who possess Provenance and Regulatory compliance offers manufacturers an added layer of assurance regarding quality and ethical sourcing. In conclusion, the integration of talc powder into the rubber manufacturing process is a decision that combines improved material performance, cost-efficiency, and environmental sensibility. For those in the rubber industry, understanding and utilizing the full potential of talc powder offers a competitive edge, enhancing product quality and meeting the rigorous demands of today's market. By choosing talc, manufacturers not only innovate their product lines but also align themselves with sustainable practices that resonate with the eco-conscious values of contemporary consumers.

Importantly, talc's compatibility with various chemical compounds makes it a versatile additive. It does not react adversely with other ingredients in the rubber mix, ensuring that the end-product maintains its designed properties and performance. This compatibility underscores talc's role in custom formulations, where precise chemical interactions are imperative for achieving specific material characteristics. From an environmental standpoint, talc powder also contributes positively. It is a naturally occurring mineral and when responsibly sourced, it embodies a renewable aspect desired in modern manufacturing. Responsible talc mining and processing thus supports efforts towards sustainable industrial practices, addressing both environmental and corporate social responsibilities. In terms of industry best practices, leveraging talc powder necessitates an understanding of its grades and specifications, which vary depending on the source. Manufacturers need to select the appropriate grade of talc to match their specific application requirements, ensuring optimal performance. Collaborating with talc suppliers who possess Provenance and Regulatory compliance offers manufacturers an added layer of assurance regarding quality and ethical sourcing. In conclusion, the integration of talc powder into the rubber manufacturing process is a decision that combines improved material performance, cost-efficiency, and environmental sensibility. For those in the rubber industry, understanding and utilizing the full potential of talc powder offers a competitive edge, enhancing product quality and meeting the rigorous demands of today's market. By choosing talc, manufacturers not only innovate their product lines but also align themselves with sustainable practices that resonate with the eco-conscious values of contemporary consumers.

Pervious