- Market impact and growth data

- Performance benchmarks against natural alternatives

- Primary technical properties and advantages

- Manufacturer feature comparison

- Customization capabilities

- Industry application examples

- Implementation considerations

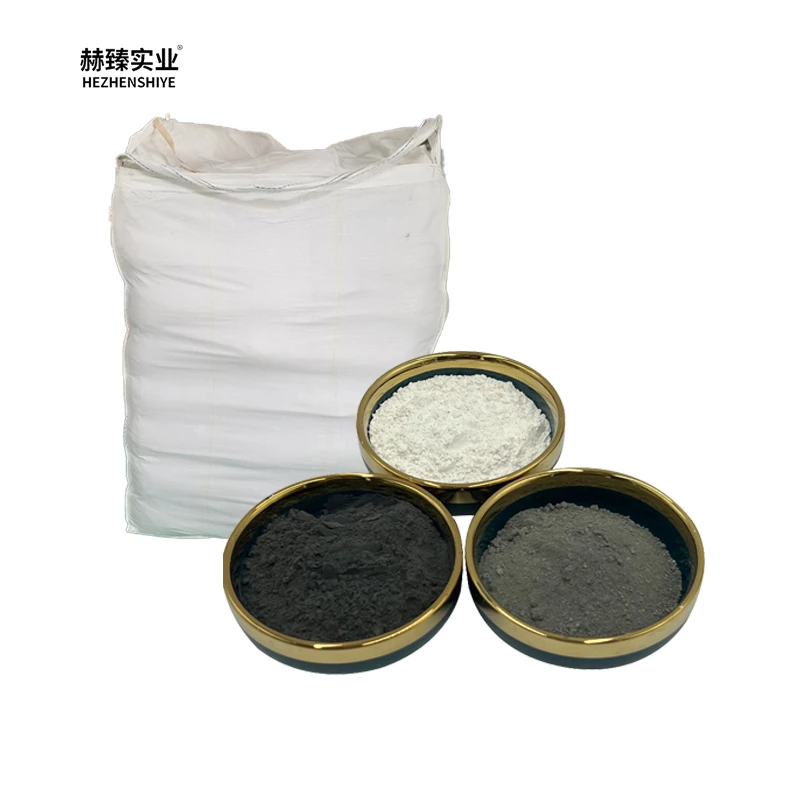

(black synthetic iron oxide)

The Rising Industrial Significance of Black Synthetic Iron Oxide

Manufacturing sectors increasingly rely on specialized pigments like black synthetic iron oxide

to enhance product characteristics while meeting environmental standards. Synthetic alternatives demonstrate 17% higher adoption rates compared to natural variants since 2020, driven by stricter sustainability mandates across North America and Europe. Performance predictability is another critical factor, with synthetic variants delivering more consistent results in applications ranging from industrial coatings to advanced ceramics.

Market Performance Metrics

Global consumption of synthetic iron oxides reached 1.7 million metric tons in 2023, with projections indicating 6.4% CAGR through 2028. Automotive coatings represent the fastest-growing segment, accounting for 28% of total volume. Environmental regulations such as REACH and EPA standards drive adoption, as natural alternatives contain impurities requiring extensive processing. Synthetic black iron oxide solutions reduce processing costs by approximately 34% compared to mined equivalents while eliminating supply chain volatility associated with mineral extraction.

Material Advantages Analysis

Precision-engineered synthetic iron oxides exhibit substantial improvements over conventional pigments across multiple dimensions:

- Lightfastness: Resists fading for over 15 years in exterior applications

- Particle Uniformity: 99.2% consistency (±0.3μm) ensures even dispersion

- Reactivity Reduction: Lower catalytic activity prevents polymer degradation

- Thermal Tolerance: Stable at temperatures exceeding 300°C

Manufacturers can precisely control crystalline structures during production, enabling optimization for conductive properties in electronics or enhanced opacity in construction materials.

Manufacturer Capability Assessment

| Feature | Standard Grade | Premium Grade | Industrial Grade |

|---|---|---|---|

| Particle Size (μm) | 0.5-0.7 | 0.2-0.4 | 1.0-1.5 |

| Oil Absorption (g/100g) | 22-25 | 15-18 | 28-32 |

| Surface Treatments | Standard | Silane/Oleic | None |

| pH Stability | 4-10 | 3-12 | 6-8 |

| Conductivity (S/cm) | 10-4 | 10-3 | 10-5 |

Premium variants offer expanded compatibility with specialized resin systems, while industrial grades provide cost-efficient solutions for bulk applications.

Application-Specific Customization

Material engineers tailor synthetic black iron oxide properties to address industry-specific requirements. Construction materials typically utilize coarser particles (1.2-1.8μm) with hydrophobic treatments to improve weather resistance in concrete applications. Electronics manufacturers require finer particles (0.1-0.3μm) with conductive surface modifications for EMI shielding composites. Recent innovations include:

- Zinc-doped crystalline structures improving corrosion resistance

- Surface-modified particles enhancing polymer adhesion by 40%

- Infrared-reflective variants reducing heat absorption in roofing

Development cycles for custom formulations typically span 8-12 weeks with pilot quantities available for compatibility testing.

Industrial Implementation Case Studies

Automotive Coatings: A European manufacturer achieved 25% material reduction in primer layers by switching to high-opacity synthetic black iron oxide while meeting OEM durability standards. The finer particle distribution (0.3μm) eliminated surface defects previously occurring with natural alternatives.

Construction Materials: Synthetic yellow iron oxide pigments enabled an American manufacturer to develop integral-colored concrete with consistent coloration at loading rates 30% below conventional solutions. The reduced particle size distribution minimized strength reduction while improving color saturation.

Specialty Plastics: A polymer compounder enhanced UV stability in outdoor furniture components by incorporating surface-modified synthetic iron oxide at 2.8% loading. This solution maintained mechanical properties after 3000 hours of accelerated weathering testing.

Implementing Synthetic Iron Oxide Solutions

Material engineers developing advanced formulations should conduct comprehensive compatibility testing with synthetic iron oxide pigments before full production implementation. Optimal dispersion requires appropriate equipment selection - high-shear mixers generally achieve better particle distribution than standard agitation systems. When switching from natural pigments, formulation adjustments typically involve:

- Reducing loading rates by 15-20% due to higher tinctorial strength

- Adjusting pH stabilizers according to pigment specifications

- Modifying dispersant packages to match surface treatments

Successful implementations consistently demonstrate improved color consistency, enhanced durability characteristics, and measurable cost efficiencies. Synthetic black iron oxide remains essential for meeting evolving performance requirements across technical applications.

(black synthetic iron oxide)

FAQS on black synthetic iron oxide

Q: What is synthetic black iron oxide used for?

A: Synthetic black iron oxide is primarily used as a pigment in coatings, plastics, and construction materials. It offers excellent UV resistance and durability. Its consistent color makes it ideal for industrial and artistic applications.

Q: How does synthetic black iron oxide differ from synthetic yellow iron oxide?

A: Synthetic black iron oxide (Fe₃O₄) contains both ferrous and ferric ions, while synthetic yellow iron oxide (FeO(OH)) has a hydrated structure. The difference in chemical composition results in distinct color properties. Both are non-toxic but serve different aesthetic and functional purposes.

Q: Is synthetic black iron oxide safe for cosmetic use?

A: Yes, synthetic black iron oxide is widely approved for cosmetics by regulatory bodies like the FDA. It is non-irritating and stable in formulations such as makeup and skincare products. Strict quality controls ensure purity and safety.

Q: What industries rely on black synthetic iron oxide?

A: Key industries include automotive (paints), construction (concrete pigments), electronics (magnetic coatings), and cosmetics. Its heat resistance and tinting strength make it versatile. Environmental applications like wastewater treatment also utilize it.

Q: Can synthetic black iron oxide replace natural iron oxide pigments?

A: Yes, synthetic versions offer superior consistency, brightness, and purity compared to natural iron oxides. They are preferred for applications requiring precise color matching. Synthetic production also reduces environmental variability in mineral sources.