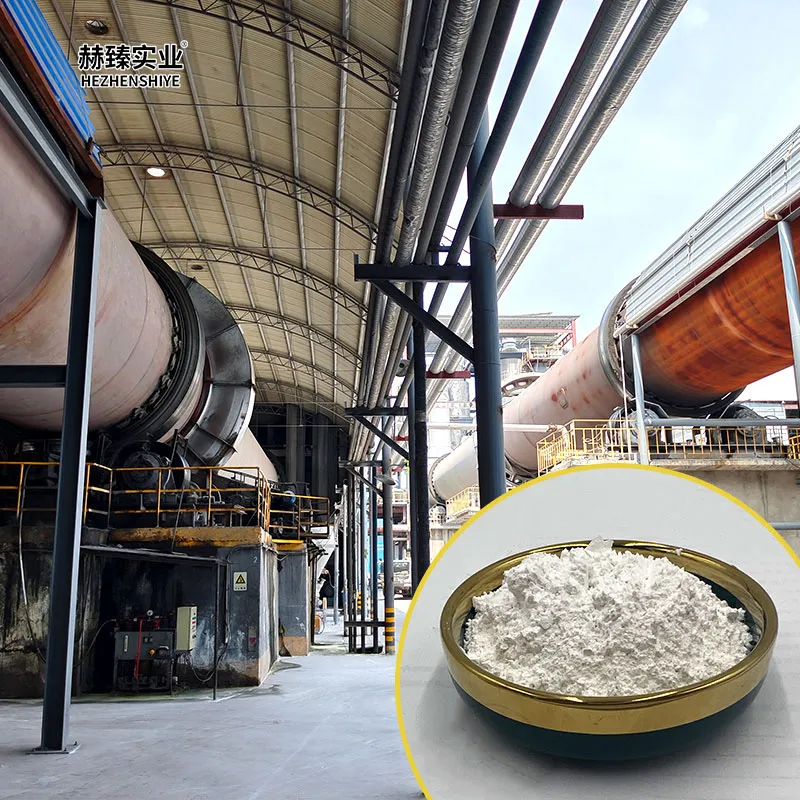

Product Description

In plastic-filled rubber formulations, calcined talc acts as a reinforcing agent, significantly improving the tensile strength, tear resistance, and wear properties of the coating. Its platelet structure allows for effective stress distribution, which enhances the overall mechanical performance of the material.

Moreover, calcined talc improves the processing characteristics of plastic-filled rubber coatings. It acts as a nucleating agent, promoting the formation of smaller, more uniform rubber particles during compounding. This leads to smoother, more consistent coatings with fewer defects.

The high whiteness and purity of calcined talc also contribute to the aesthetic appeal of plastic-filled rubber coatings. It provides a clean, uniform appearance that enhances the visual appeal of coated products.

Additionally, calcined talc is known for its excellent chemical inertness and thermal stability. These properties make it an ideal choice for applications requiring resistance to chemicals, heat, and UV radiation.

In conclusion, calcined talc is a valuable addition to plastic-filled rubber coatings, offering enhanced mechanical performance, improved processing characteristics, and superior aesthetic appeal. Its versatility makes it a go-to ingredient for formulating high-quality, durable coatings across various industries.

| Cas No. | 14807-96-6 |

| Place of Origin | China |

| Color | White/Gray |

| Shape | Powder |

| Purity | 90-95% |

| Grade | industrial Grade Food Grade |

| Package | 25kg/bag,customized package |

| MOQ | 1kg |

Banner PDF

Banner PDF Get A Quote

Get A Quote