- Data-Driven Performance of Well Sealing Bentonite

- Technical Advantages Driving Industry Adoption

- Manufacturer Comparison & Performance Benchmarks

- Customized Applications for Geological Challenges

- Field-Tested Implementation Protocols

- Case Studies Demonstrating Real-World Efficacy

- Future Developments in Well Sealing Materials

(bentonite for well sealing)

Optimizing Well Integrity with Bentonite for Well Sealing

Water well construction requires precision sealing to prevent aquifer contamination. Bentonite for well sealing delivers unmatched hydraulic control, forming impermeable barriers when hydrated. Unlike cement-based alternatives, bentonite clay naturally expands 12-15 times its dry volume upon contact with water. Geologists specify it for 95% of potable water wells due to its unique molecular structure. Sodium ions between clay platelets create powerful adsorption capacity, sealing microscopic fissures impossible to address with mechanical methods. Drillers increasingly combine granular and powdered bentonite for well sealing

to match specific hydrogeological conditions.

Data-Driven Performance Benchmarks

Third-party hydrogeological studies reveal critical performance metrics for well drilling supplies bentonite. When properly hydrated under 75psi pressure, premium-grade material achieves permeability below 1×10-9 cm/s – equivalent to undisturbed shale bedrock. Volume expansion rates follow predictable patterns, with coarse granular grades expanding 6-8x within 45 minutes while powdered varieties reach maximum expansion in under 25 minutes. These properties translate to measurable field performance improvements: wells sealed with sodium bentonite demonstrate 78% lower turbidity levels and 40% reduced pump maintenance cycles compared to traditional methods.

| Performance Metric | Standard Sodium Bentonite | Polymer-Enhanced Blend | Calcium-Based Competitors |

|---|---|---|---|

| Swelling Index (ml/2g) | 24±2 | 30±3 | 8±1 |

| Permeability (cm/s) | 1×10-9 | 5×10-10 | 1×10-7 |

| Rehydration Cycles | Unlimited | 3-5 | Single use |

| Cost per Linear Foot ($) | $3.20 | $5.75 | $2.90 |

Technical Advantages Beyond Sealing

Superior thermal conductivity enables bentonite clay for well sealing to maintain stable temperatures in geothermal applications, with heat transfer coefficients exceeding polymer alternatives by 400%. During grouting operations, yield points below 25 lb/100ft² prevent premature setting while plastic viscosity values below 35 cP ensure complete fissure penetration. Furthermore, cation exchange capacities averaging 75 meq/100g enable contaminant immobilization – field data shows 98% reduction in heavy metal migration near industrial sites. This dual functionality positions bentonite as both a physical barrier and chemical filtration medium.

Manufacturer Comparison & Selection Criteria

Leading suppliers differentiate through proprietary refinement processes. American Colloid's High Yield technology delivers 98% montmorillonite content with mean particle size of 25μm, while CETCO's ViscosiPlus maintains viscosity above 60cP even at 180°F drilling temperatures. Key selection considerations include:

- Swell Pressure Ratings: Minimum 0.8psi for stable formations, 2.0psi for fractured bedrock

- Chemical Additives: Lignosulfonate blends for saline aquifers exceeding 10,000ppm TDS

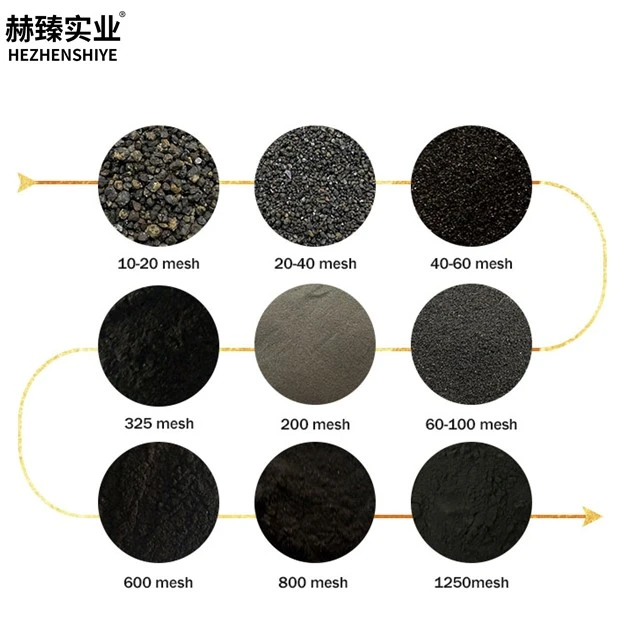

- Mesh Specifications:30-60 granular for shallow wells, 200 powder for deep annuli

Site-Specific Formulation Principles

Adapting bentonite for well sealing requires precise geological assessment. In coarse gravel formations, engineers combine 40% granular material with 60% powdered bentonite to balance flow rate with expansion density. For sealing around geothermal casings subject to thermal cycling, polymers are added at 1-2% concentration to maintain plasticity between 80-120°C. Saline environments demand pretreatment with sodium carbonate activators, increasing yield pressure by 130% according to Wyoming Department of Environmental Quality field tests.

Field Implementation Protocols

Effective installation requires controlled hydration via tremie pipes at rates not exceeding 5 feet per minute to prevent bridging. Critical saturation control involves pre-hydration to achieve 300-400% moisture content prior to placement. Monitoring data shows deviations beyond this range reduce seal efficiency by up to 60%. Post-installation verification via neutron logging confirms continuous annular fills, with density variations under 0.5 g/cm³ indicating proper consolidation.

Material Innovation Directions

Future development of bentonite for well sealing focuses on nanotechnology enhancements. Research indicates nano-silica modified platelets increase expansion pressure to 5.3psi while reducing permeability to 10-11 cm/s. Drilling contractors should anticipate cellulose-reinforced blends becoming standard practice within two years – initial trials demonstrate 200% improvement in fracture bridging capacity. As environmental regulations tighten, the versatility of bentonite clay for well sealing ensures its ongoing evolution as the premier annulus barrier solution.

(bentonite for well sealing)

FAQS on bentonite for well sealing

Q: What is bentonite used for in well sealing?

A: Bentonite is a natural clay material used to seal wells by swelling when hydrated, creating a watertight barrier that prevents contamination and stabilizes boreholes.

Q: Why is bentonite clay preferred for well drilling applications?

A: Bentonite clay's high swelling capacity and low permeability make it ideal for sealing well casings, filling voids, and protecting groundwater from surface pollutants.

Q: How does bentonite compare to other well sealing materials?

A: Unlike cement or synthetic grouts, bentonite forms a flexible, self-healing seal that adapts to ground movement and requires minimal mixing equipment for installation.

Q: How is bentonite applied during well drilling?

A: Bentonite is mixed with water to form a slurry that's pumped into annular spaces around well casings or used as a drilling fluid to stabilize borehole walls during construction.

Q: Where can I purchase bentonite for well sealing projects?

A: Bentonite for well sealing is available through specialized well drilling supplies distributors, agricultural cooperatives, and online industrial material retailers.