Hezhen Park road luminous stone fluorescent runway stone high luminous gravel garden fish tank

2025.03.05

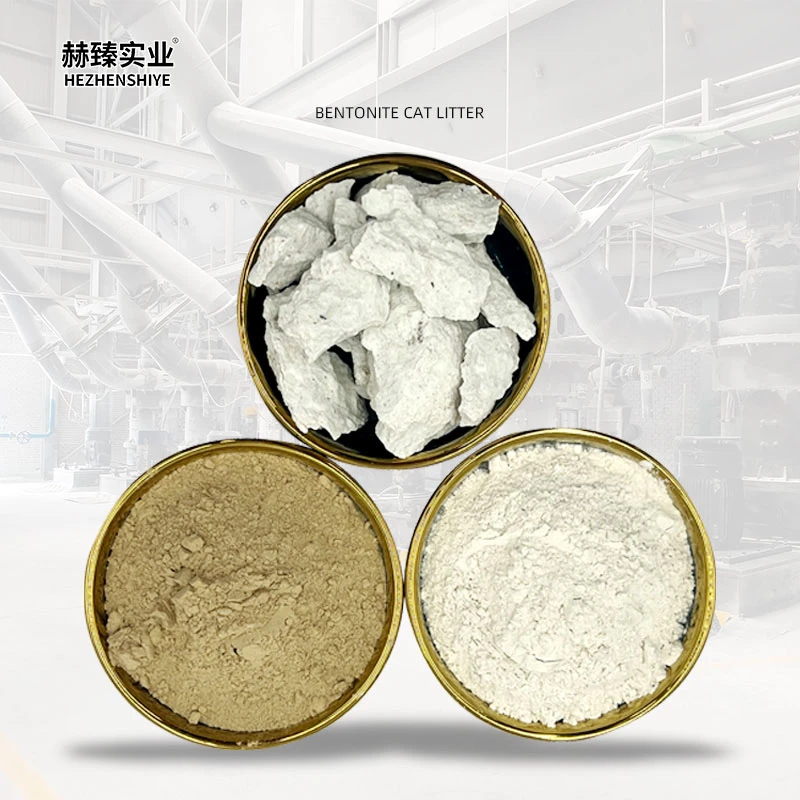

Bentonite, a versatile clay with several industrial applications, stands as a linchpin for numerous industries worldwide. For those delving into its production or seeking a reputable source, understanding the manufacturing nuances, coupled with an insight into the leadership of a reliable bentonite manufacturer, is quintessential.

Industrial demand for bentonite spans a diverse range—from construction to cosmetics. In drilling operations, a bentonite slurry acts as a dreaded drilling fluid, providing stability to boreholes and effectively cooling and lubricating drill bits. Its expansive properties make it an invaluable ingredient in geotechnical applications, where it seals leakage pathways in soil and prevents water seepage. This adaptability underscores the expertise required from a bentonite manufacturer, as they must not only produce high-quality bentonite but also tailor it to meet varied industrial demands. For bentonite used in environmental remediation, manufacturers might have to enhance its absorption properties. This ensures the clay can better capture and immobilize contaminants, crucial for sites aiming to mitigate environmental hazards. Manufacturers often staff experienced engineers and geologists who guide the customization processes, ensuring their bentonite products deliver optimal performance in field applications. The cosmetic industry’s reliance on bentonite for skincare products further showcases the need for authoritative manufacturing. Recognized for its detoxifying properties, bentonite clay is a key ingredient in face masks and creams, offering impurity extraction and a soothing effect for the skin. Here, manufacturers must adhere to cosmetic-grade production practices, ensuring the clay is free from contaminants and allergens. Partnering with dermatologists and skincare specialists, reputable manufacturers devise formulations that align with global cosmetic regulations while delivering promised benefits. Sustaining a competitive edge in bentonite manufacturing also involves embracing innovation. This might entail investing in R&D, exploring new applications, or pioneering novel processing techniques to enhance the clay’s inherent properties. Some manufacturers lead in utilizing AI and machine learning to optimize production efficiencies and reduce environmental footprints further, embodying both expertise and forward-thinking. Ultimately, selecting a bentonite manufacturer is not merely about cost or proximity. It involves evaluating a provider’s commitment to quality, innovation, and customer satisfaction. The ideal manufacturer operates as a partner, extending beyond mere transactions to offer guidance, customization, and consistent support. For businesses seeking to harness the power of bentonite, aligning with a reputable manufacturer is undoubtedly a decision that will pay dividends, ensuring reliability and excellence in all applications.

Industrial demand for bentonite spans a diverse range—from construction to cosmetics. In drilling operations, a bentonite slurry acts as a dreaded drilling fluid, providing stability to boreholes and effectively cooling and lubricating drill bits. Its expansive properties make it an invaluable ingredient in geotechnical applications, where it seals leakage pathways in soil and prevents water seepage. This adaptability underscores the expertise required from a bentonite manufacturer, as they must not only produce high-quality bentonite but also tailor it to meet varied industrial demands. For bentonite used in environmental remediation, manufacturers might have to enhance its absorption properties. This ensures the clay can better capture and immobilize contaminants, crucial for sites aiming to mitigate environmental hazards. Manufacturers often staff experienced engineers and geologists who guide the customization processes, ensuring their bentonite products deliver optimal performance in field applications. The cosmetic industry’s reliance on bentonite for skincare products further showcases the need for authoritative manufacturing. Recognized for its detoxifying properties, bentonite clay is a key ingredient in face masks and creams, offering impurity extraction and a soothing effect for the skin. Here, manufacturers must adhere to cosmetic-grade production practices, ensuring the clay is free from contaminants and allergens. Partnering with dermatologists and skincare specialists, reputable manufacturers devise formulations that align with global cosmetic regulations while delivering promised benefits. Sustaining a competitive edge in bentonite manufacturing also involves embracing innovation. This might entail investing in R&D, exploring new applications, or pioneering novel processing techniques to enhance the clay’s inherent properties. Some manufacturers lead in utilizing AI and machine learning to optimize production efficiencies and reduce environmental footprints further, embodying both expertise and forward-thinking. Ultimately, selecting a bentonite manufacturer is not merely about cost or proximity. It involves evaluating a provider’s commitment to quality, innovation, and customer satisfaction. The ideal manufacturer operates as a partner, extending beyond mere transactions to offer guidance, customization, and consistent support. For businesses seeking to harness the power of bentonite, aligning with a reputable manufacturer is undoubtedly a decision that will pay dividends, ensuring reliability and excellence in all applications.