Silicon dioxide, a compound with a wide range of applications and significance, has become an integral part of various industries, including food, manufacturing, and more. Understanding its meaning, usage, and how it's produced is crucial for both professionals and consumers. Let's delve into the details of silicon dioxide, from its role as a silica as food additive to the diverse ways it's silicon dioxide used and what it truly means.

Silica as Food Additive: Safety and Function

Silica as food additive plays a vital role in the food industry. It is primarily used as an anti - caking agent, preventing ingredients from clumping together. For example, in powdered food products like spices, coffee creamer, and baking mixes, silica helps maintain a free - flowing texture. This ensures that the products are easy to measure and use. Silica is generally recognized as safe (GRAS) by regulatory authorities when used within approved limits. It doesn't react with the food ingredients, nor does it add any flavor or color. Instead, it quietly does its job of keeping products in a desirable physical state, enhancing their shelf life and usability.

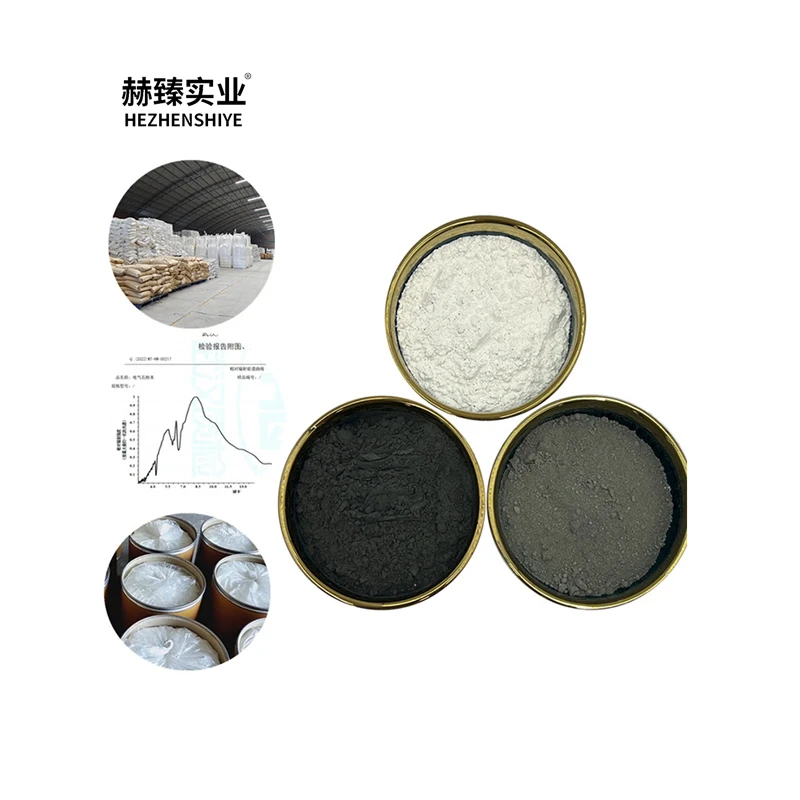

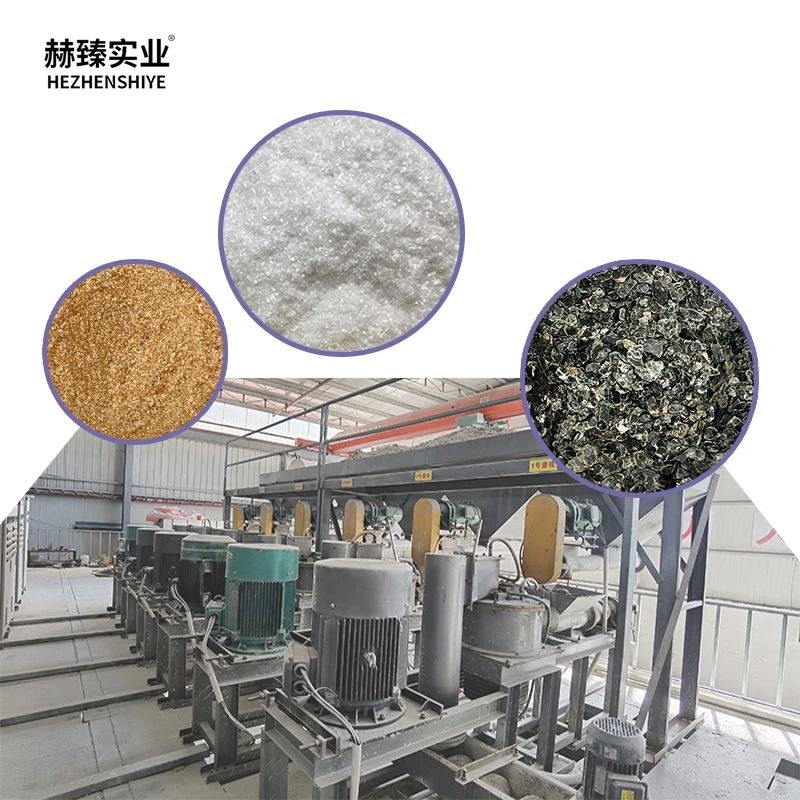

Silicon Dioxide Made From: Production Sources and Methods

Silicon dioxide made from various sources and through different processes. Naturally, it can be obtained from minerals such as quartz, which is abundant in the Earth's crust. In industrial production, silica sand (a form of silicon dioxide) is often a primary starting material. Chemical synthesis is another common method. For instance, it can be produced by reacting silicon - containing compounds with oxygen or water - based reagents. Some high - purity silicon dioxide used in specialized applications, like the semiconductor industry, is made through highly controlled chemical vapor deposition processes. These methods allow for the production of silicon dioxide with specific properties tailored to different end - uses.

Silicon Dioxide Meaning: A Chemical and Practical Perspective

The silicon dioxide meaning extends beyond its simple chemical formula (SiO₂). Chemically, it represents a compound formed by the combination of silicon and oxygen atoms. Structurally, it can exist in different forms, such as crystalline and amorphous. In practical terms, silicon dioxide has diverse meanings depending on the context. In the construction industry, it's a key component in making concrete and glass, providing strength and durability. In electronics, it serves as an insulator in microchips, enabling the proper functioning of circuits. And in the pharmaceutical industry, it can be used as an excipient in medications, helping with the formulation and stability of drugs. So, its meaning encompasses a wide range of functions and importance across multiple sectors.

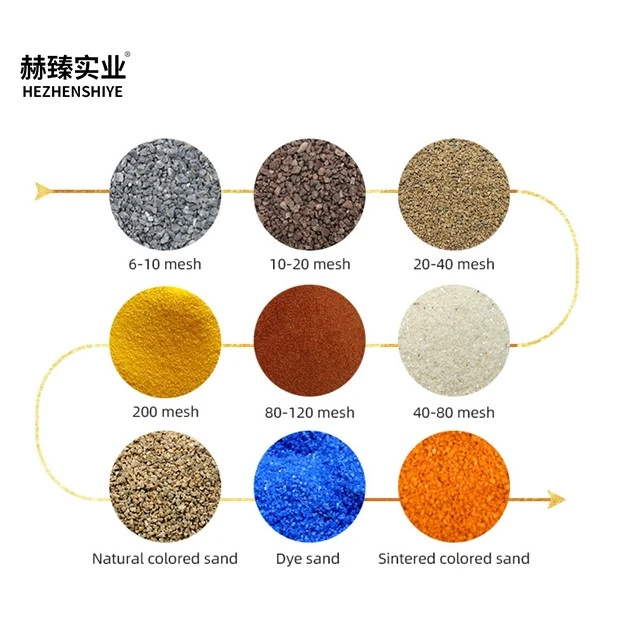

Silicon Dioxide Usage: Diverse Applications Across Industries

The silicon dioxide usage is incredibly diverse. In the cosmetics industry, it's used as an absorbent and thickening agent. It helps control the texture of products like powders, lotions, and deodorants, giving them a smooth and pleasant feel. In the paint and coating industry, silicon dioxide is added to improve hardness, scratch resistance, and weather resistance. It also helps in pigment dispersion, ensuring a uniform color. In water treatment, it can be used in filtration processes to remove impurities. Additionally, in the rubber industry, it acts as a reinforcing filler, enhancing the mechanical properties of rubber products. These are just a few examples of how widely silicon dioxide is utilized in different industries.

Silicon Dioxide Used: Meeting Specific Product Requirements

Silicon dioxide used is carefully selected and formulated to meet specific product requirements. For example, in the production of optical fibers, ultra - pure silicon dioxide is used to ensure high - quality light transmission. In the food industry, the grade of silica used as an additive is carefully regulated to ensure safety and effectiveness. In the automotive industry, silicon dioxide - based materials are used in tires to improve traction and reduce rolling resistance, contributing to fuel efficiency. Different forms and grades of silicon dioxide are chosen based on factors such as particle size, purity, and surface properties to achieve the desired performance in each application.

Silicon Dioxide FAQs

Is silica as a food additive harmful to health?

When used within the approved limits set by regulatory bodies, silica as a food additive is considered safe. It generally passes through the digestive system without being absorbed. However, excessive consumption of any additive, including silica, may pose risks. But under normal circumstances of using food products with approved levels of silica, there is no significant threat to human health.

What are the main natural sources of silicon dioxide?

The main natural sources of silicon dioxide include quartz, sandstone, and flint. Quartz is one of the most common minerals on Earth and is a primary source. Sand, which is often composed mainly of silicon dioxide, is another abundant natural source. These natural materials are mined and processed to obtain silicon dioxide for various industrial uses.

How does silicon dioxide improve the performance of paints?

Silicon dioxide in paints improves performance in several ways. It increases the hardness of the paint film, making it more resistant to scratches and abrasion. It also enhances weather resistance, protecting the paint from UV radiation, moisture, and other environmental factors. Additionally, it helps in the dispersion of pigments, ensuring a more even and consistent color finish.

Can silicon dioxide be recycled?

In some cases, silicon dioxide - containing materials can be recycled. For example, glass, which has silicon dioxide as a major component, is widely recycled. However, the recycling process for silicon dioxide - based materials depends on the specific product and its form. Some industrial applications may make it more challenging to recycle, but efforts are continuously being made to improve recycling rates for silicon dioxide - containing products.

Are there any alternatives to silicon dioxide in its various applications?

There are some alternatives to silicon dioxide in certain applications. For example, in some anti - caking applications in the food industry, other substances like calcium silicate can be used. In some cosmetics, alternative thickening and absorbent agents may be employed. However, silicon dioxide's unique properties often make it the preferred choice in many applications, and finding suitable alternatives that match all its characteristics can be difficult.