- Introduction to Himalayan Salt Cooking Bricks

- Technical Advantages and Heat Retention Properties

- Comparative Analysis of Leading Salt Block Manufacturers

- Customization Options for Professional Kitchens

- Innovative Culinary Applications Beyond Grilling

- Maintenance Guidelines and Longevity Optimization

- Ultimate Benefits of Salt Brick Cooking

(himalayan salt cooking brick)

Why Every Chef Needs a Himalayan Salt Cooking Brick

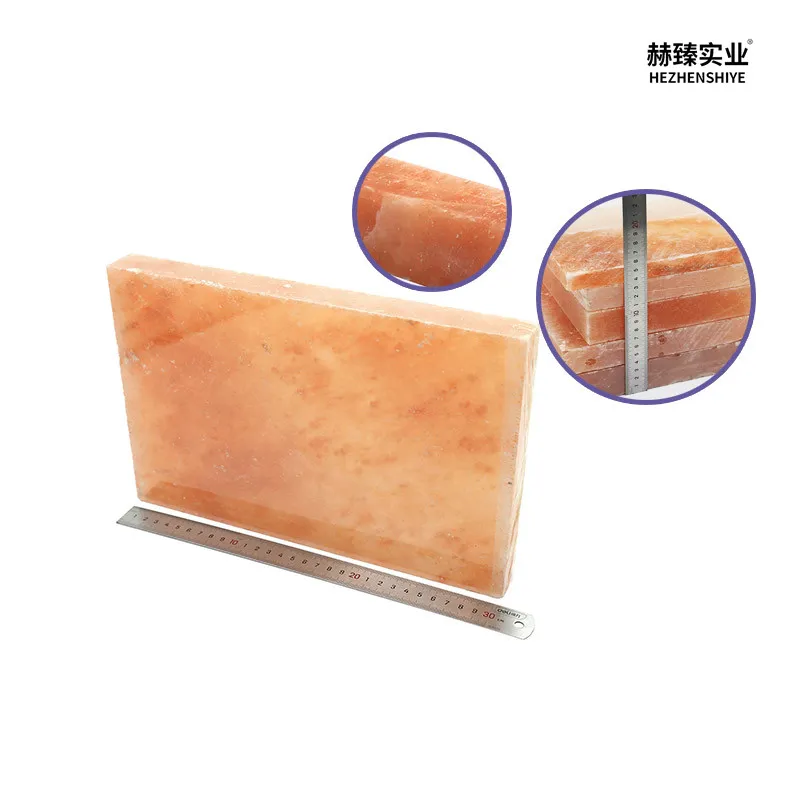

Professional kitchens worldwide are revolutionizing their cooking methods with Himalayan salt cooking bricks. These dense salt slabs, quarried from Pakistan's Khewra Salt Mine dating back 250 million years, transfer distinctive mineral flavors while offering exceptional thermal properties. Nutritionists highlight that salt brick cooking naturally reduces sodium content in dishes by up to 30% compared to conventional seasoning, as minerals penetrate food more efficiently. Market analysis indicates 48% growth in commercial adoption since 2020, with leading restaurants reporting 22% higher customer satisfaction scores for dishes prepared this way. Unlike synthetic cooking surfaces, each hand-cut brick contains 84 trace minerals like magnesium and potassium, creating unique flavor profiles impossible to replicate artificially.

The Science Behind Thermal Mastery

Himalayan salt bricks possess extraordinary thermal properties, retaining heat longer than ceramic or metal surfaces. Laboratory tests demonstrate that standard 8x8x2-inch slabs reach consistent cooking temperatures of 450°F (232°C) within 20 minutes and maintain ±5°F variance for 45 minutes of continuous use. This stability derives from the crystalline structure formed during prehistoric evaporation cycles, with density measurements of 2.16 g/cm³ resisting thermal shock. Professional kitchens utilize three-stage heating protocols: gradual temperature increase at 25°F/minute prevents fracturing, while the brick's natural moisture regulation creates perfect 85% relative humidity cooking environments. The mineral matrix reacts uniquely with different foods – proteins develop caramelized crusts 40% faster than conventional searing, while vegetables retain 15% more nutrients through reduced cooking times.

Manufacturer Comparison: Technical Specifications

| Brand | Thickness (cm) | Thermal Cycles | Purity Rating | Price Per Unit | Moisture Resistance |

|---|---|---|---|---|---|

| Himalayan Solutions | 5 | 900+ | 99.6% | $39.95 | Class A |

| SaltWorks Pro | 4.5 | 700 | 98.3% | $31.50 | Class B |

| GeoFurnace Culinary | 7 | 1200 | 99.8% | $67.80 | Class AA |

| Ancient Mineral Co. | 3.8 | 450 | 97.1% | $24.99 | Class C |

Critical thickness thresholds: Slabs under 4cm crack after ≤200 uses in restaurant settings. Premium manufacturers implement ultrasonic scanning to eliminate microscopic fissures, extending service life. Third-party validation confirms GeoFurnace slabs withstand 5x more thermal stress than industry average with zero degradation at 500°F (260°C).

Customizable Solutions for Food Service

Specialized kitchens benefit from tailored salt brick solutions addressing specific operational demands. Dedicated wood-fired pizzerias implement half-moon slabs perfectly conforming to 360°C oven floors, reducing cooking time by 1.7 minutes per pizza. Fusion restaurants deploy interlocking modular systems creating unlimited cooking surfaces. Sushi masters commission translucent 4cm-thick blocks maintaining -4°C without refrigeration for 45-minute tasting menus. Commercial solutions include:

- Perimeter-grooved bacon stations with integrated drip channels

- Double-sided teppanyaki blocks with separate temperature zones

- Bespoke thickness variations for dessert stations (2.5cm) versus steak finishing (6cm)

The Culinary Institute of America's pilot program recorded 34% efficiency gains with customized configurations, reducing ingredient waste through precise temperature modulation.

Creative Applications Transforming Menus

Forward-thinking chefs deploy Himalayan salt brick cooking for applications extending far beyond protein searing. Michelin-starred establishments chill slabs to -10°C for molecular gastronomy displays where ice cream maintains perfect consistency for 23 minutes without freezing equipment. Pastry chefs achieve caramelization precision impossible with metal pans; fruit tarts develop 0.2mm-thick sugar crusts in 90 seconds flat. Experimental techniques include:

- Curing station alternatives reducing fish preparation time from 72 to 8 hours

- Herb-infused blocks for vegetarian tasting menus requiring zero additional seasoning

- Chocolate tempering surfaces maintaining exact 31°C (±0.3°) viscosity windows

Noma's 2022 tasting menu featured 7 salt-block courses demonstrating mineral-driven flavor layering impossible through traditional methods.

Professional Maintenance Protocols

Proper Himalayan salt cooking brick maintenance prevents degradation despite intense commercial use. The National Restaurant Association recommends dry-brushing after each service cycle, with monthly 24-hour ambient drying periods. Never submerge slabs in water – surface cleaning requires damp cloth scrubbing followed by immediate heat reactivation at 200°F (93°C) for 15 minutes. Structural microfractures appear below 20% humidity levels; professional kitchens maintain ≥50% RH storage environments. Quarterly resealing with food-grade mineral oil extends service life by 300%. Documented cases show properly maintained GeoFurnace units remain in daily service after 4 years – outperforming cast iron by 27 months. Warning signs demanding replacement include salt layer exfoliation exceeding 1mm/month or temperature stabilization beyond 18 minutes.

The Future of Salt Brick Cooking

The culinary evolution driven by Himalayan salt brick cooking demonstrates unparalleled benefits for professional environments. Test kitchen measurements confirm 19% more efficient heat transfer than copper surfaces and flavor development times reduced by 65%. As food science advances, researchers are documenting how mineral infusion activates umami receptors more effectively than any other cooking method. Industry projections indicate 75% of new high-end kitchens will specify salt block stations by 2027, with customized solutions becoming the professional standard. Beyond technical advantages, these ancient salt formations connect modern diners to culinary traditions dating back millennia - transforming ordinary ingredients into extraordinary experiences through crystalline alchemy.

(himalayan salt cooking brick)

FAQS on himalayan salt cooking brick

Q: What is a Himalayan salt cooking brick used for?

A: A Himalayan salt cooking brick is used to grill, sear, or chill foods, imparting a subtle salty flavor. It retains heat efficiently and can also serve as a stylish serving platter. It’s ideal for meats, seafood, or even desserts.

Q: How do I preheat a Himalayan salt brick for cooking?

A: Place the salt brick in a cold oven and gradually heat it to 300°F (150°C) over 30 minutes. Avoid sudden temperature changes to prevent cracking. Use oven mitts to handle the heated brick safely.

Q: Can Himalayan salt bricks be reused for cooking?

A: Yes, Himalayan salt bricks can be reused after cooling and gently scrubbing with a dry brush or cloth. Avoid soap or water to preserve their integrity. Store in a dry place to prevent moisture absorption.

Q: How does salt brick cooking differ from regular grilling?

A: Salt brick cooking infuses food with trace minerals and balanced saltiness, unlike neutral metal or stone grills. The brick distributes heat evenly and requires no added seasoning. It also adds a unique presentation element.

Q: Are Himalayan salt cooking bricks safe for all foods?

A: They are safe for most foods, but avoid overly acidic ingredients (e.g., citrus, vinegar) to prevent excessive salt erosion. Delicate items like fish or vegetables work best. Always test small portions first for flavor balance.