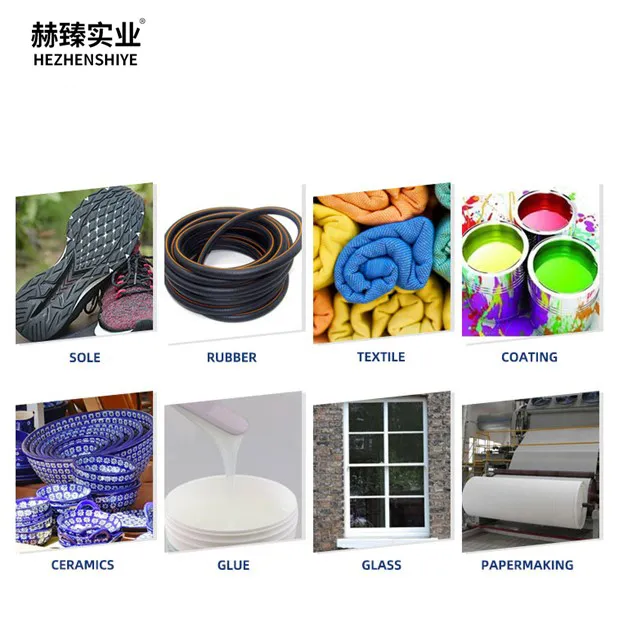

In today’s competitive market, product aesthetics are as crucial as functionality. SiO2 powder (silicon dioxide) has emerged as a game-changer for manufacturers seeking to elevate surface quality while optimizing costs. This versatile additive transforms finishes across industries—from automotive coatings to premium kitchenware—by enhancing clarity, scratch resistance, and tactile appeal. As a leading supplier, Hebei Hezhen Industrial Co., Ltd. leverages 15+ years of expertise in precipated silica production to deliver solutions that marry visual excellence with cost efficiency. This analysis explores how integrating silicon dioxide powder revolutionizes product aesthetics, focusing on its role in elevating consumer goods like double-wall French presses.

Elevating Surface Clarity with SiO2 Powder

SiO2 powder acts as an invisible artisan in manufacturing, refining surfaces to optical perfection. When added to coatings or composites, its nano-scale particles fill microscopic imperfections, creating flawlessly smooth finishes. For products like double-wall French presses, this translates to crystal-clear glass that resists hazing or cloudiness even after repeated washes. The silicon dioxide powder achieves this by forming a uniform matrix within materials, scattering light evenly to eliminate visual distortions. This property is especially valuable for transparent products, where clarity directly signals quality to consumers. Beyond optics, the powder’s hardness (rated 7 on the Mohs scale) fortifies surfaces against fine scratches that dull appearance over time. Manufacturers partnering with experts like Hebei Hezhen gain access to tailored particle sizes—from 10nm to 5μm—to match specific transparency requirements without compromising structural integrity.

Enhancing Tactile Appeal Using Precipated Silica

Precipated silica redefines how products feel in the hand, turning everyday items into luxury experiences. In double-wall French presses, it’s infused into polymer grips or glass coatings to create velvety-smooth textures that resist stickiness from oils or residues. Unlike abrasive fillers, this silicon dioxide powder variant bonds molecularly with base materials, eliminating gritty sensations while boosting slip resistance. The result? A French press that feels substantial yet effortless to grip, pour, and clean. This tactile enhancement stems from silica’s unique morphology: its porous structure absorbs excess resins or plasticizers during production, preventing the "tacky" feel that plagues cheaper alternatives. For manufacturers, precipated silica offers processing advantages too—its moisture control properties accelerate drying times in coatings, reducing defects like bubbles or uneven curing that compromise hand-feel.

Balancing Cost and Quality with Silicon Dioxide Powder Price

Strategic investment in silicon dioxide powder delivers premium aesthetics without inflating production budgets. While fumed silica offers nano-scale precision, its vapor-phase production raises costs significantly. In contrast, precipated silica provides 80-90% of the performance benefits at 30-50% lower silicon dioxide powder price points—making it ideal for high-volume goods like kitchenware. Hebei Hezhen optimizes this balance through advanced processing: by controlling reaction temperatures and pH levels during precipitation, they achieve tighter particle distribution (see table below), reducing waste and maximizing coverage per kilogram.

|

Parameter |

Fumed Silica |

Precipated Silica |

|

Avg. Particle Size |

10-20 nm |

5-100 μm |

|

Production Method |

Vapor-phase |

Wet precipitation |

|

Relative Cost Index |

High |

Medium |

|

Clarity Enhancement |

Exceptional |

Excellent |

This cost efficiency allows brands to invest in thicker coatings or multi-layer finishes—critical for French presses exposed to thermal stress—while maintaining retail price competitiveness.

Ensuring Sustainable Brilliance via Precipated Silica

Precipated silica isn’t just a performance enhancer; it’s an eco-conscious choice aligning with global sustainability trends. Derived from quartz sand via closed-loop processes, it generates 60% less CO₂ than fumed alternatives while utilizing recyclable byproducts like sodium sulfate. In double-wall French presses, silica-infused glass resists etching from acidic cleaners, extending product lifespans and reducing replacement waste. Hebei Hezhen amplifies these benefits through ISO 9001-certified production, minimizing water/energy use while ensuring heavy-metal-free outputs safe for food-contact applications.

Boosting Visual Brilliance with SiO2 Powder: FAQs

How does SiO2 powder prevent clouding in glass products?

SiO2 powder fills microscopic pores during melting, creating denser glass that resists moisture ingress and mineral deposits—the main causes of cloudiness in items like French presses.

Why choose precipated silica over other additives for coatings?

Precipated silica offers superior light diffusion and hardness at optimal silicon dioxide powder price points, making it ideal for achieving luxury finishes without luxury costs.

Is silicon dioxide powder safe for food-contact products?

Absolutely. When sourced from certified suppliers like Hebei Hezhen, silicon dioxide powder meets FDA/EC1935 standards for food safety, with no leaching risks.

Can precipated silica enhance color vibrancy?

Yes! Its light-scattering properties intensify pigment depth in colored glass or plastics, making reds richer and blues more vivid without extra dyes.

How does SiO2 powder impact production efficiency?

Its moisture-control properties accelerate curing times in coatings, while easy dispersion cuts mixing energy by up to 40% versus clumping alternatives.

Transform Surfaces, Elevate Value—Partner with Hebei Hezhen Industrial Co., Ltd. for premium SiO2 powder solutions. Our expertise in precipated silica ensures your products marry stunning aesthetics with uncompromising durability. Explore https://www.hezhenshiye.com/ to discover cost-efficient paths to visual brilliance, or contact our team for technical guidance tailored to your manufacturing needs. Where science meets artistry—silicon dioxide powder excellence starts here.