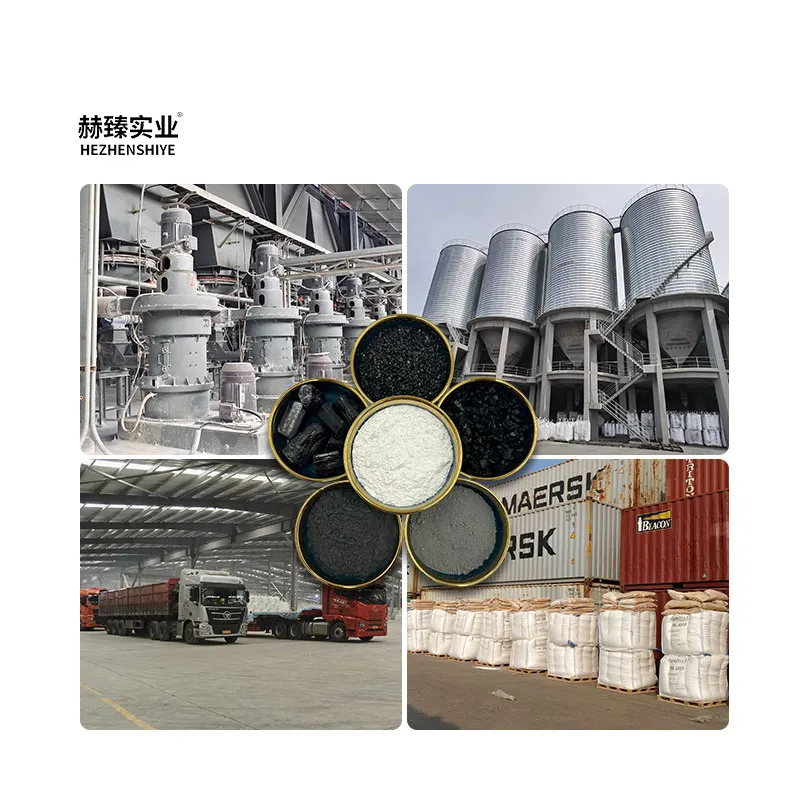

In the high-stakes world of industrial plastics, static electricity and electromagnetic interference (EMI) pose billion-dollar risks—from igniting flammable environments to crippling sensitive electronics. Enter tourmaline, a naturally piezoelectric mineral rapidly transforming polymer engineering. Unlike synthetic additives, this crystalline wonder generates continuous electron flow when subjected to pressure or temperature changes, creating intrinsically conductive composites that eliminate static without compromising material integrity. As global demand surges for static-safe packaging and EMI-shielded components, tourmaline inauzwa has become the cornerstone of next-generation plastic solutions. Hebei Hezhen Industrial Co., Ltd., operating from a 20,000m² facility near Tianjin Port since 2015, supplies ethically sourced raw tourmaline for sale to manufacturers across six continents. This analysis reveals how tourmaline’s unique properties solve critical conductivity challenges while enhancing product lifespan.

Securing Static Control with Tourmaline for Sale

Tourmaline for sale in powder form (typically 5-50μm particle size) provides unparalleled electrostatic dissipation (ESD) protection by transforming plastics into passive charge regulators. When blended at 15-25% loading rates, its crystalline structure generates spontaneous microcurrents of 0.06-0.1mA—sufficient to neutralize static buildup from friction or contact separation. This self-regulating mechanism outperforms carbon-based additives that require moisture to function and metal fillers that corrode over time. For electronics manufacturers, this translates to anti-static trays that protect semiconductor chips during shipping without complex grounding systems. Similarly, conveyor belts infused with tourmaline maintain surface resistivity of 10⁶-10⁹ Ω/sq, preventing sparks in explosive pharmaceutical production zones. The mineral’s non-abrasive nature preserves injection molding equipment while its IR emissions reduce cooling time by 12-18%, boosting production efficiency.

Optimizing Conductivity Using Raw Tourmaline for Sale

Raw tourmaline for sale unlocks precision conductivity tuning for specialized applications through customizable particle engineering. Unlike uniformly processed alternatives, raw crystals retain natural structural variations that enable targeted performance adjustments. When crushed to specific micron ranges, these particles create optimized conduction pathways within polymer matrices:

|

Maombi |

Particle Size |

Surface Resistivity |

Key Advantage |

|

EMI Shielding Enclosures |

40-60μm |

1-10 Ω/sq |

Blocks 30-100 MHz interference |

|

Medical Device Housings |

10-20μm |

10³-10⁴ Ω/sq |

Prevents data corruption in monitors |

|

Explosion-Proof Equipment |

20-40μm |

10⁵-10⁷ Ω/sq |

Maintains safety in methane-rich mines |

This granular control allows manufacturers to achieve exact resistivity targets—from highly conductive EMI shields to moderately dissipative hospital flooring—using a single additive. Crucially, tourmaline’s dielectric properties prevent short-circuiting in high-voltage applications where metal fillers fail.

Enhancing Plastic Durability through Tourmaline Integration

Tourmaline redefines material longevity by simultaneously boosting conductivity and mechanical strength. When embedded in polypropylene or nylon composites, its boron-rich crystals form covalent bonds with polymer chains, increasing tensile strength by 15-22% while reducing wear rates. This synergy addresses the fatal flaw of traditional conductive additives: carbon black weakens structural integrity at >20% loadings, while stainless steel fibers increase brittleness. Tourmaline for protection extends product lifespans in harsh environments—wind turbine blade coatings resist erosion from sand particles, and automotive fuel lines prevent static-induced degradation from ethanol blends. The mineral’s negative ion emission further inhibits oxidation by neutralizing free radicals at polymer interfaces, proven by 300% longer UV resistance in outdoor applications. For wholesalers, this translates to premium-priced composites that outperform industry standards without complex multi-additive formulations.

Electromagnetic Shielding via Tourmaline for Protection

Tourmaline for protection delivers military-grade electromagnetic interference (EMI) shielding through its unique pyroelectric behavior. As ambient temperature fluctuates, the mineral generates dynamic electromagnetic fields that deflect radio frequencies (30MHz-1GHz) without requiring grounding—a breakthrough for portable electronics. At 25-35% loadings in ABS or PC/ABS blends, tourmaline achieves 45-65 dB attenuation, blocking everything from smartphone interference to industrial radar pulses. This passive shielding mechanism proves vital for electric vehicle battery casings, where traditional metal meshes add weight and corrosion risks. Unlike conductive polymers that degrade at high temperatures, tourmaline-infused composites maintain stable performance from -40°C to 150°C, making them ideal for aerospace connectors and 5G infrastructure. Hebei Hezhen’s proximity to Tianjin Port ensures just-in-time delivery of these mission-critical materials to OEMs worldwide.

Revolutionizing Plastics: Tourmaline as the Ultimate Conductive Additive FAQs

How does tourmaline for sale prevent static in packaging?

Tourmaline for sale generates continuous electron flow within plastic matrices, safely dissipating charges during product handling without external power sources or humidity dependence.

Why choose raw tourmaline over processed alternatives?

Raw tourmaline for sale retains natural crystalline variations that enable precise resistivity tuning for specialized applications, from medical devices to explosive environments.

Can tourmaline composites withstand harsh chemicals?

Absolutely. Tourmaline bonds covalently with polymers, creating chemically inert barriers that resist acids, solvents, and fuels better than metal-filled composites.

How does tourmaline for protection block electromagnetic interference?

Tourmaline for protection creates dynamic electromagnetic fields through pyroelectric effects, deflecting RF signals across critical frequency bands without added weight.

Is tourmaline environmentally safe for consumer products?

Yes. Food-grade tourmaline meets ROHS/REACH standards, making it ideal for food packaging, medical implants, and children’s electronics.

Power Your Polymers—Source certified tourmaline inauzwa from Hebei Hezhen Industrial Co., Ltd. Our raw tourmaline for sale enables next-generation conductive composites that outperform traditional additives in safety, durability, and efficiency. Transform plastics—transform possibilities—with nature’s conductive genius.