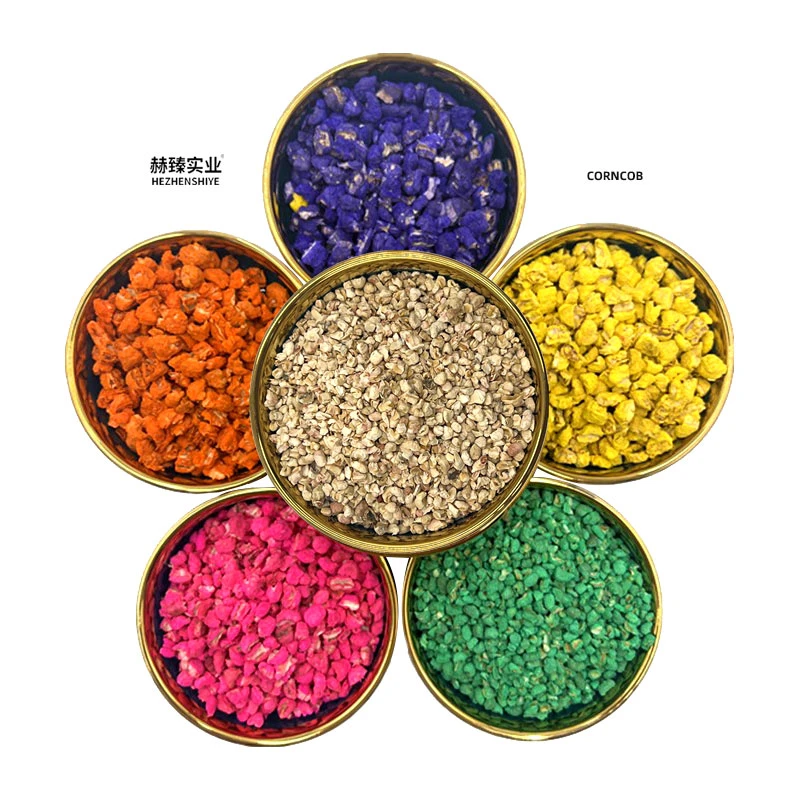

Corncob granules for building materials pet bedding glass industry chemical raw materials papermaking industry

Corn cob granules are derived from the central, cylindrical core of corn cobs, the byproduct of corn (maize) harvesting. After the kernels are removed, these cobs, which were once considered mere agricultural waste, undergo a series of processes to transform into valuable granular products with diverse applications.

The production of corn cob granules begins with the collection of corn cobs from farms. These cobs are typically gathered after the corn kernels have been mechanically stripped for food, feed, or industrial uses. Once collected, the cobs are transported to processing facilities, where the first step involves cleaning to remove any residual kernels, dirt, or other contaminants. This ensures the purity of the final product.

Following cleaning, the corn cobs are dried to reduce their moisture content significantly. Drying is crucial as it enhances the cobs' durability, prevents mold growth, and makes them easier to process. Drying can occur through natural methods, such as sun-drying in open fields or under sheds, or through artificial means using industrial dryers. After drying, the cobs are ready to be transformed into granules.

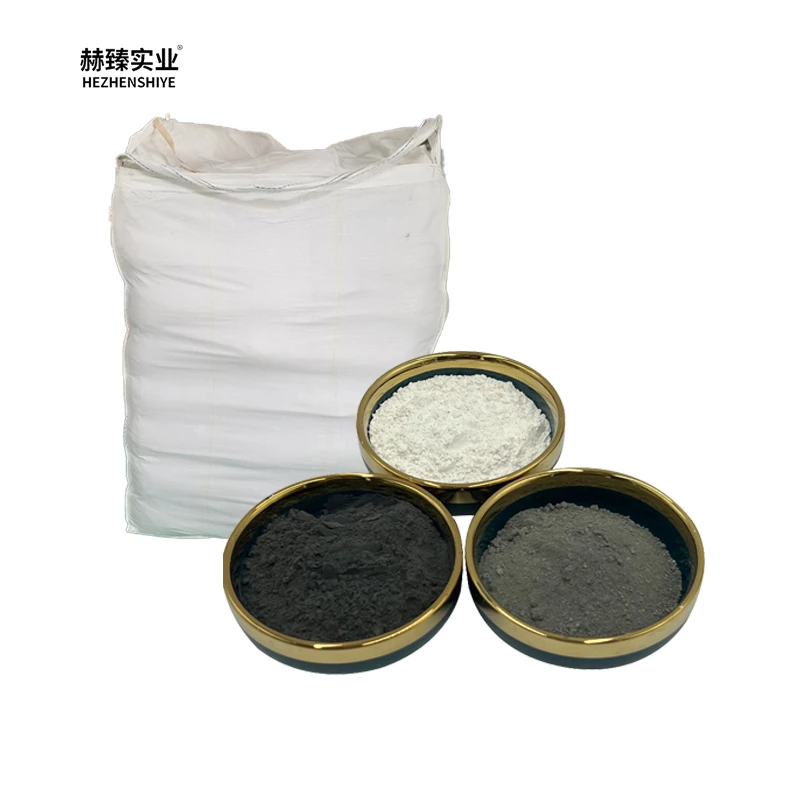

The granulation process involves crushing and grinding the dried corn cobs into small, uniform particles. Specialized machinery, such as hammer mills or roller mills, is used to achieve the desired granule size. Depending on the intended application, the granules can range in size from fine powders to larger, coarser particles. After granulation, the particles may undergo further screening to separate them into different grades based on size, ensuring consistency within each batch.

Corn cob granules possess several unique properties that make them highly useful. They are rich in cellulose, hemicellulose, and lignin, which contribute to their mechanical strength and absorbency. Their porous structure allows them to soak up liquids effectively, making them ideal for applications that require high absorbency.

In the industrial realm, corn cob granules serve as an excellent abrasive material. Their hardness and granular texture make them suitable for sandblasting, polishing, and cleaning various surfaces without causing excessive scratching. They are used in the manufacturing of precision parts, where a gentle yet effective cleaning method is required. Furthermore, corn cob granules are employed in the production of activated carbon, which is used for water purification, air filtration, and in the pharmaceutical industry for drug purification.

In the agricultural sector, corn cob granules are often used as livestock bedding. Their absorbent nature helps to keep animal stalls dry, reducing the risk of infections and improving animal welfare. They also provide a comfortable surface for animals to rest on. Additionally, these granules can be added to animal feed as a source of dietary fiber, promoting healthy digestion in livestock.