Silicon dioxide, a compound with the chemical formula silicon dioxide sio2, is an incredibly important substance with a vast range of applications and forms. From its amorphous state to its role in creating unique materials like black white carbon, silicon dioxide has firmly established itself as a crucial element in numerous industries. Let's take a deep dive into the different aspects of silicon dioxide, exploring its various forms, uses, and significance.

Understanding Amorphous SiO2

Amorphous sio2, also known as non - crystalline silicon dioxide, is a form of silicon dioxide that lacks the ordered atomic structure of its crystalline counterparts. This unique structure gives it distinct properties and applications. Amorphous SiO2 is often used in the production of glass, where its ability to form a stable, transparent matrix is highly valued. In the electronics industry, it serves as an insulator in semiconductor devices, helping to prevent unwanted electrical conduction and protect sensitive components. It can also be found in coatings, where its hardness and chemical resistance enhance the durability of surfaces. Additionally, in the field of optics, amorphous SiO2 - based materials are used to manufacture lenses and optical fibers, enabling the transmission of light over long distances with minimal loss.

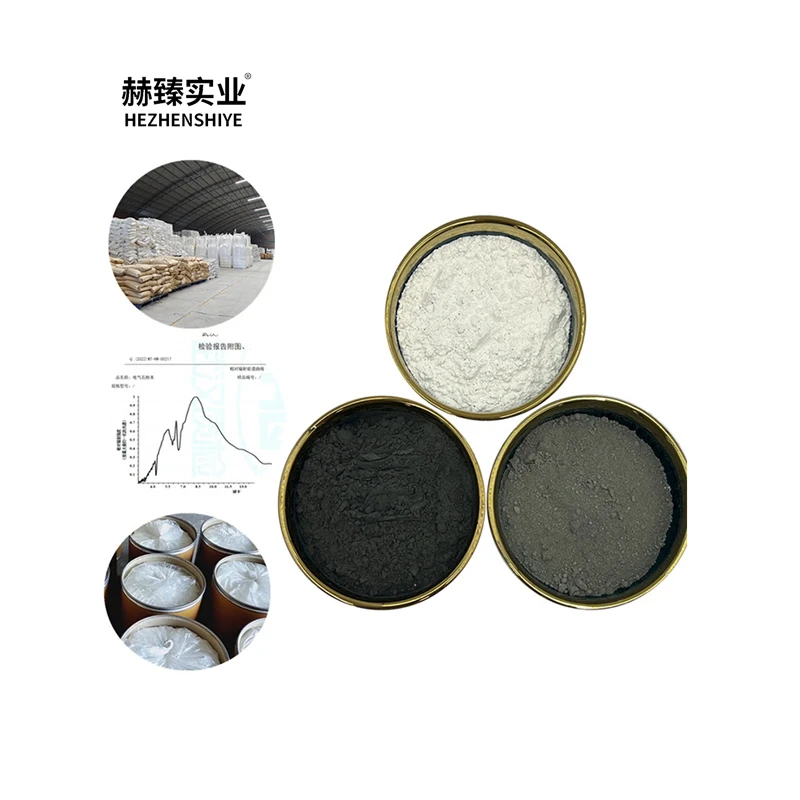

The Intriguing Black White Carbon

Black white carbon, which is closely related to silicon dioxide, is a fascinating material with unique characteristics. Although the term might seem a bit paradoxical, black white carbon typically refers to forms of carbon - containing materials that incorporate silicon dioxide in some way. In certain applications, black white carbon can be used as a reinforcing filler in rubber products. The presence of silicon dioxide in these materials enhances the mechanical properties of rubber, such as its strength, abrasion resistance, and durability. This makes it ideal for use in tires, conveyor belts, and other rubber - based products that need to withstand high stress and friction. Moreover, black white carbon can also be used in the production of inks and coatings, providing unique visual and performance properties, like high opacity and good adhesion.

The Fundamental Silicon Dioxide SiO2

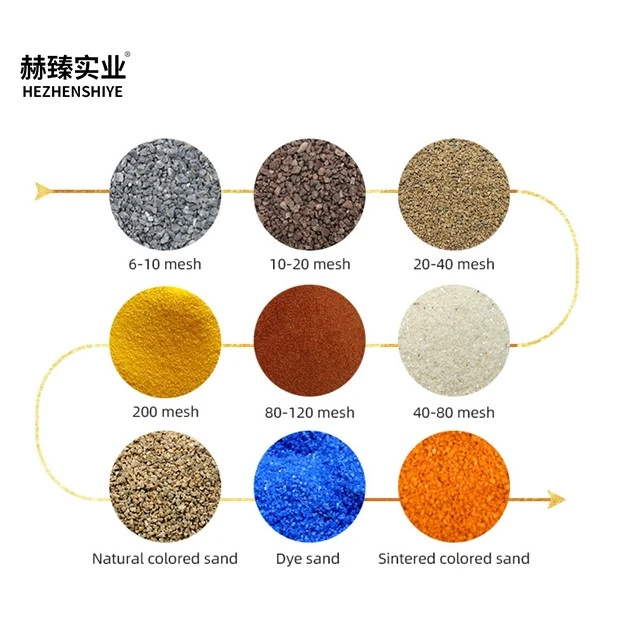

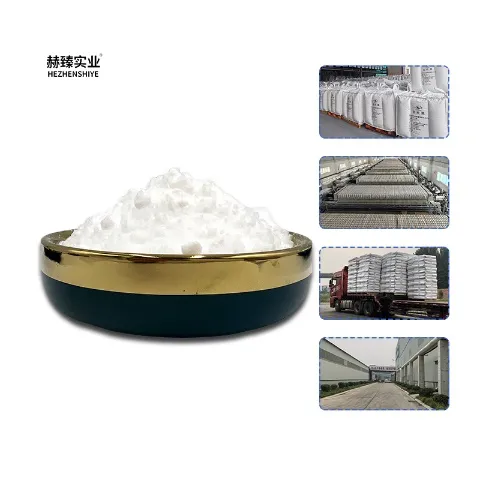

Silicon dioxide sio2 in its pure form is one of the most abundant compounds on Earth. It exists naturally in various forms, including quartz, sand, and cristobalite. Its chemical stability and physical properties make it a cornerstone of many industries. In the construction industry, silicon dioxide is a key component of cement and concrete. It reacts with other substances during the hydration process to form a strong, rigid matrix that holds buildings and infrastructure together. In the food industry, it is used as an anti - caking agent to prevent powdered foods from clumping. It is also employed in the production of ceramics, where it contributes to the strength, hardness, and heat resistance of the final products. From the microscale in semiconductor manufacturing to the large - scale in construction, silicon dioxide's presence is ubiquitous and essential.

The Diverse Uses of Silicon Dioxide

ال silicon dioxide use spans across a multitude of sectors. In the cosmetics industry, it is used in products like face powders and eyeshadows. Its fine - particle size and absorbent properties help to control oil, improve the texture of the products, and enhance their staying power. In the pharmaceutical industry, silicon dioxide is used as an excipient in tablet formulations. It helps to bind the active ingredients together, improve the flowability of the powder during tablet manufacturing, and ensure consistent dosage. In water treatment, it can be used in the form of activated silica to remove impurities and clarify water. Additionally, in the automotive industry, silicon dioxide is used in the production of paints and coatings to provide scratch resistance and a glossy finish.

Exploring the Use of Silicon Dioxide

ال استخدام ثاني أكسيد السيليكون is not only limited to traditional industries but is also expanding into emerging fields. In the field of nanotechnology, silicon dioxide nanoparticles are being studied for their potential in drug delivery systems. Their small size allows them to penetrate cells more easily, and they can be engineered to carry drugs precisely to the targeted areas in the body. In the renewable energy sector, silicon dioxide - based materials are being explored for use in solar cells. They can help to improve the efficiency of light absorption and charge separation, making solar energy conversion more effective. Moreover, in the field of environmental remediation, silicon dioxide - based adsorbents are being developed to remove pollutants from air and water, contributing to a cleaner and more sustainable environment.

Silicon Dioxide FAQs

Is silicon dioxide harmful to humans?

In most common forms and applications, silicon dioxide is generally considered safe for humans. For example, when used as an anti - caking agent in food or an excipient in pharmaceuticals, it poses minimal risk. However, inhaling large amounts of fine - particulate silicon dioxide, such as in the form of crystalline silica dust in certain industrial settings, can lead to serious health problems like silicosis, a lung disease. So, proper safety measures are required in such environments.

How is amorphous SiO2 different from crystalline SiO2?

Amorphous SiO2 lacks the long - range ordered atomic structure that crystalline SiO2 has. This difference in structure leads to variations in properties. Amorphous SiO2 typically has lower melting points, different optical properties, and often better chemical resistance in some applications compared to its crystalline counterparts. Crystalline SiO2, on the other hand, may have higher hardness and different electrical properties in certain forms.

Can black white carbon be used in all rubber products?

While black white carbon can be used in many rubber products to enhance their properties, it may not be suitable for all applications. Some rubber formulations may require specific types of fillers based on factors like the end - use environment, temperature requirements, and desired performance characteristics. Additionally, the cost and processing requirements of using black white carbon also need to be considered for each specific rubber product.

What are the latest developments in the use of silicon dioxide?

Recent developments include the use of silicon dioxide in advanced nanomaterials for energy storage, such as in supercapacitors. There is also ongoing research into using silicon dioxide - based materials for carbon capture and storage to combat climate change. In the electronics field, new applications of silicon dioxide in next - generation semiconductor devices are being explored to meet the growing demand for faster and more efficient electronic products.

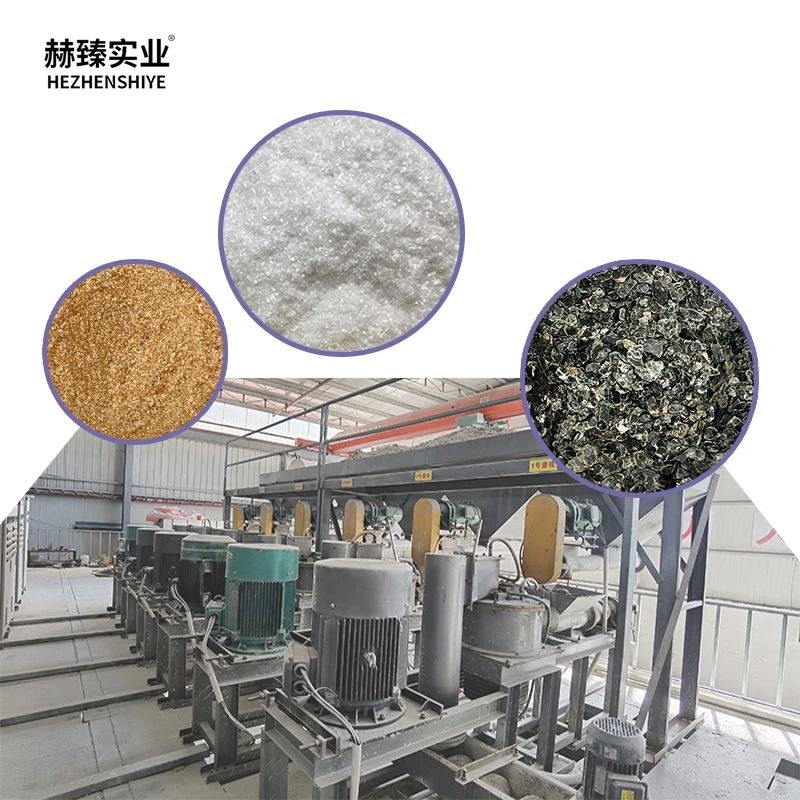

How is silicon dioxide extracted?

Silicon dioxide can be extracted from natural sources like sand and quartz. The extraction process often involves crushing and grinding the raw materials, followed by purification methods such as flotation, magnetic separation, and chemical leaching to remove impurities. For high - purity silicon dioxide used in electronics and other high - tech applications, additional processing steps like chemical vapor deposition or sol - gel techniques may be employed to further refine the material.