Industrial grade bentonite powder montmorillonite for wastewater treatment efficiently adsorbing heavy metals and organic pollutants suitable for chemical and textile wastewater purification

With the escalating stringency of global environmental protection regulations, the remediation of industrial wastewater laden with heavy metals like lead, cadmium, and chromium, as well as organic contaminants such as phenols and dyes, has emerged as a critical challenge for the chemical, textile, and electroplating sectors. Bentonite powder, a natural, cost-effective, and highly efficient adsorbent, has garnered significant attention in the realm of wastewater treatment. This is primarily attributed to its expansive specific surface area, ranging from 100-800 m²/g, and its potent adsorption capabilities, which stem from the unique layered structure of montmorillonite, the key active component within bentonite powder.

Montmorillonite in bentonite powder exhibits a high density of negative charges on its surface. This characteristic enables it to attract positively charged heavy metal ions through electrostatic forces, facilitating their removal from wastewater. Concurrently, the interlayer space of montmorillonite acts as a trapping mechanism for organic pollutant molecules. By leveraging van der Waals forces and hydrogen bonding, it effectively sequesters these molecules, thereby achieving a high degree of wastewater purification.

Bentonite Powder in Chemical Wastewater Treatment

In the domain of chemical wastewater treatment, especially for effluents containing phenols and anilines—commonly found in pharmaceutical and dye synthesis processes—bentonite powder demonstrates outstanding adsorption performance. When the dosage of bentonite powder is optimized within the range of 2-5 g/L, the removal rate of phenols can reach an impressive 92%-98%. This effectively reduces the phenol concentration in treated wastewater from an initial 500-1000 mg/L to below 0.5 mg/L, fully complying with national first-class emission standards.

A practical example can be observed in a chemical plant located in Jiangsu Province. They incorporated our industrial-grade bentonite powder into their wastewater advanced treatment process. Prior to treatment, the chemical oxygen demand (COD) of the wastewater fluctuated between 350-450 mg/L, and the chroma was measured at 800-1000 times. After adding 3 g/L of bentonite powder and subjecting the mixture to 60 minutes of stirring, remarkable results were achieved. The COD decreased significantly to 45-60 mg/L, and the chroma was reduced to 50-80 times. Moreover, the treatment cost per ton of wastewater was slashed by 30% compared to the traditional use of activated carbon. This cost reduction and efficiency improvement can be attributed to the dual functionality of bentonite powder: its strong adsorption capacity, combined with excellent flocculation properties. Bentonite powder forms large flocs with pollutants, accelerating the sedimentation process and enhancing overall treatment efficiency.

Bentonite Powder in Textile and Electroplating Wastewater Treatment

For textile printing and dyeing wastewater, which is characterized by high chroma, high salinity, and resistance to degradation, modified bentonite powder—such as acid-modified or organic-modified montmorillonite—proves to be more effective. Acid modification, typically achieved using 10%-20% hydrochloric acid, etches the surface of montmorillonite, creating additional pores and increasing the specific surface area. Organic modification, involving the use of cationic surfactants like cetyltrimethylammonium bromide, alters the surface charge of montmorillonite, thereby enhancing its affinity for anionic dyes, such as reactive red and disperse blue.

Experimental tests have shown that organic-modified bentonite powder can achieve a dye removal rate of 95%-99%, which is 20%-30% higher than that of unmodified bentonite powder. In the treatment of electroplating wastewater, bentonite powder also demonstrates remarkable efficacy in adsorbing heavy metals like copper, nickel, and zinc. When the pH value of the electroplating wastewater is adjusted to the optimal range of 6-8, the adsorption rate of copper ions by bentonite powder can exceed 98%, and the residual copper ion concentration can be brought down to ≤0.05 mg/L, meeting the most stringent environmental standards.

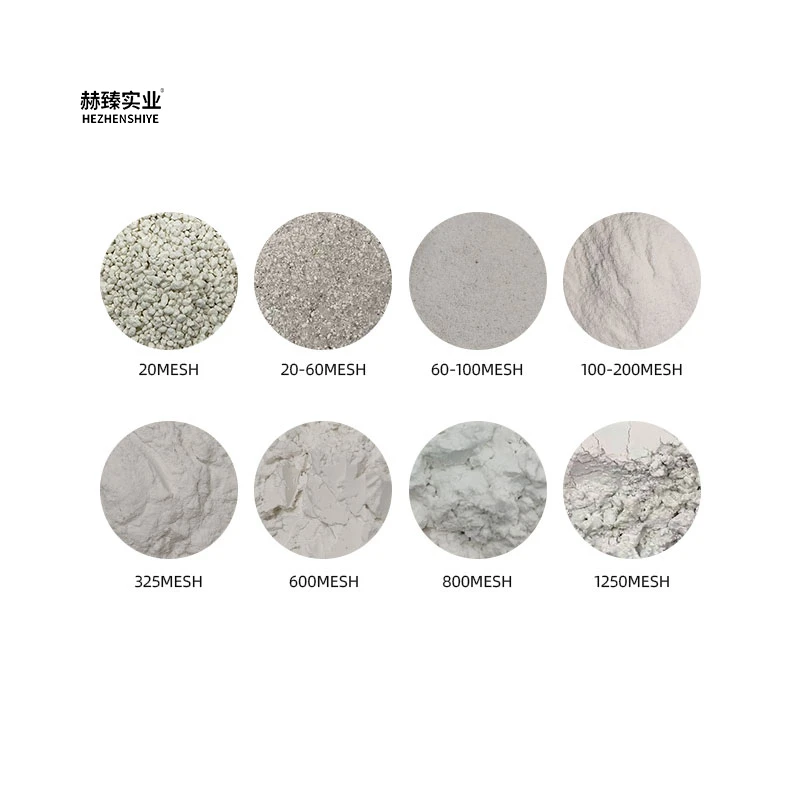

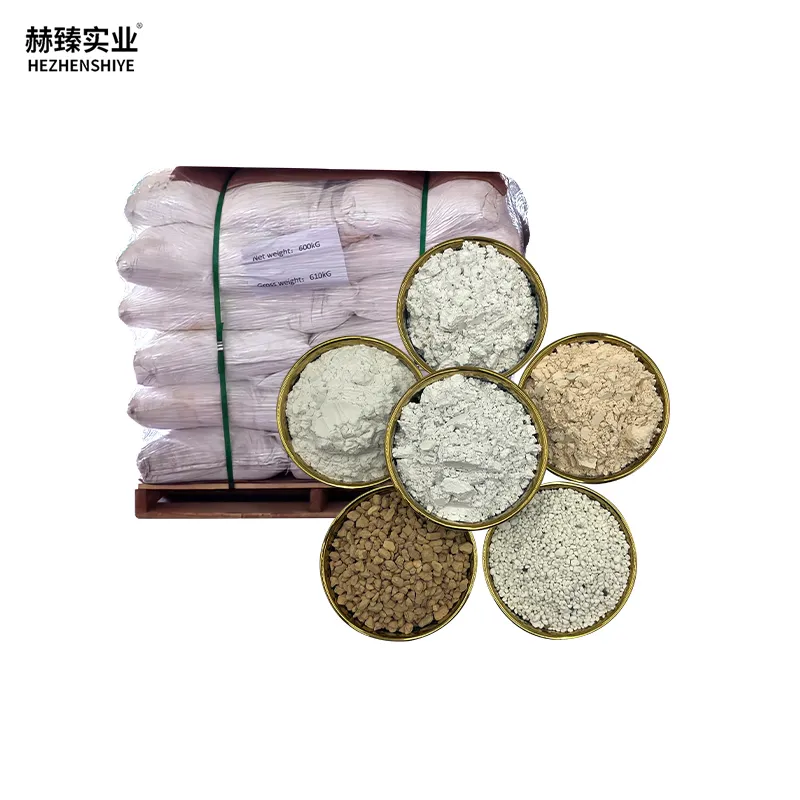

Our Industrial-Grade Bentonite Powder Specifications

Our industrial-grade bentonite powder for wastewater treatment is available in three distinct specifications: unmodified, acid-modified, and organic-modified. The montmorillonite content in these products ranges from 75% to 92%, ensuring a high level of purity and effectiveness.

- Unmodified Bentonite Powder: With a moisture content ≤10% and a particle size of 100-300 mesh, this variant is well-suited for the treatment of general heavy metal wastewater. Its natural structure allows for efficient capture of heavy metal ions through electrostatic attraction.

- Acid-Modified Bentonite Powder: Boasting a specific surface area ≥500 m²/g, this type of bentonite powder is optimized for organic wastewater treatment. The increased surface area, resulting from acid etching, provides more sites for the adsorption of organic pollutants.

- Organic-Modified Bentonite Powder: Characterized by a cation exchange capacity (CEC) ≥100 meq/100g, this specification is designed for the treatment of high-salinity dyeing wastewater. The modified surface charge enables it to effectively adsorb anionic dyes and other charged contaminants present in such complex wastewater matrices.

All our bentonite powder products undergo rigorous quality control testing. The adsorption capacity is evaluated using the methylene blue adsorption method, which provides a reliable measure of the product's effectiveness in removing organic contaminants. Additionally, heavy metal leaching tests are conducted in accordance with GB 5085.3-2007 standards, ensuring that no secondary pollution is introduced during the wastewater treatment process.

In conclusion, bentonite powder, with its versatile properties and cost-effective nature, offers a sustainable solution for industrial wastewater treatment. The unique characteristics of montmorillonite within bentonite powder make it an invaluable resource in the fight against water pollution, and our range of high-quality products, coupled with comprehensive support services, ensures that customers can achieve optimal treatment results while adhering to environmental regulations.