Turmalin has emerged as a game-changing multifunctional additive in the industrial coatings sector, addressing the growing demand for high-performance solutions that enhance durability, safety, and environmental resilience. As a naturally occurring crystalline mineral, Tourmaline possesses unique intrinsic properties—including permanent piezoelectricity, thermoelectricity, and ion-exchange capabilities—that make it an ideal candidate for resolving key challenges in coating formulations. Unlike conventional additives that often focus on a single function (such as UV resistance or corrosion protection), Tourmaline delivers multiple benefits simultaneously: it boosts antistatic performance to prevent electrostatic discharge (ESD) risks, enhances weatherability to withstand extreme temperatures and moisture, and improves adhesion to both plastic and metal substrates. Its cost-effectiveness, combined with non-toxic and eco-friendly characteristics, further solidifies Tourmaline’s position as a sustainable choice for manufacturers aiming to align with strict industry safety standards and green production goals.

Tourmaline’s antistatic properties are particularly valuable in industrial coatings applied to sensitive equipment, such as electronics manufacturing facilities or fuel storage tanks

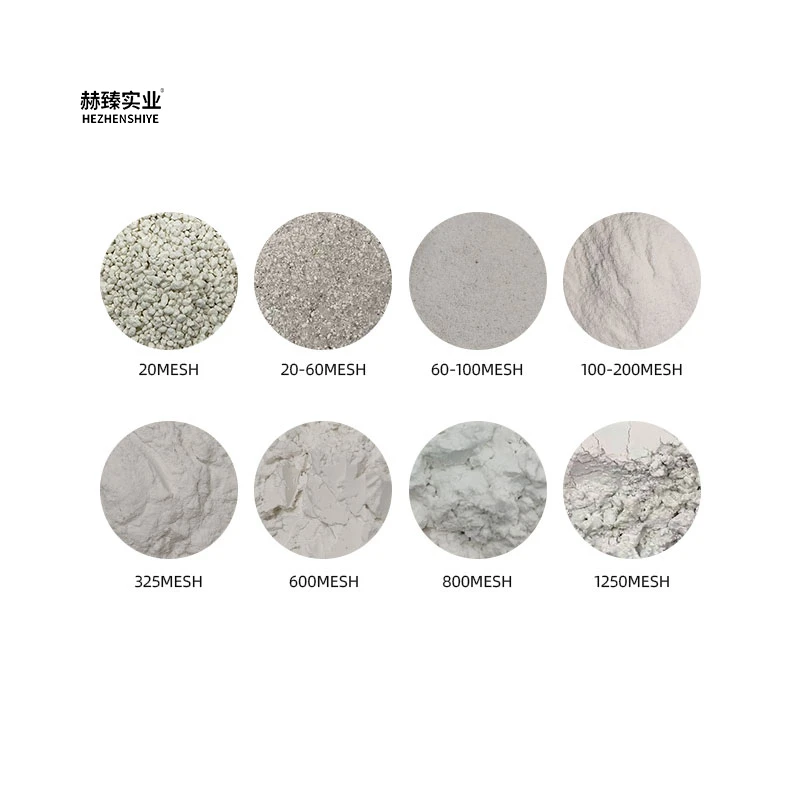

When integrated into coating formulations, fine Tourmaline powder creates a conductive network that dissipates static charges, reducing the risk of sparks that could ignite flammable materials or damage electronic components. This permanent antistatic effect—unlike temporary treatments that wear off over time—remains effective even after prolonged exposure to friction, humidity, or chemical cleaners. Additionally, Tourmaline’s ion-exchange ability helps neutralize harmful ions on the coating surface, preventing the buildup of dust and contaminants that can compromise both appearance and functionality. This dual action of static dissipation and surface purification makes Tourmaline an indispensable additive for coatings in high-risk and precision-driven industries.

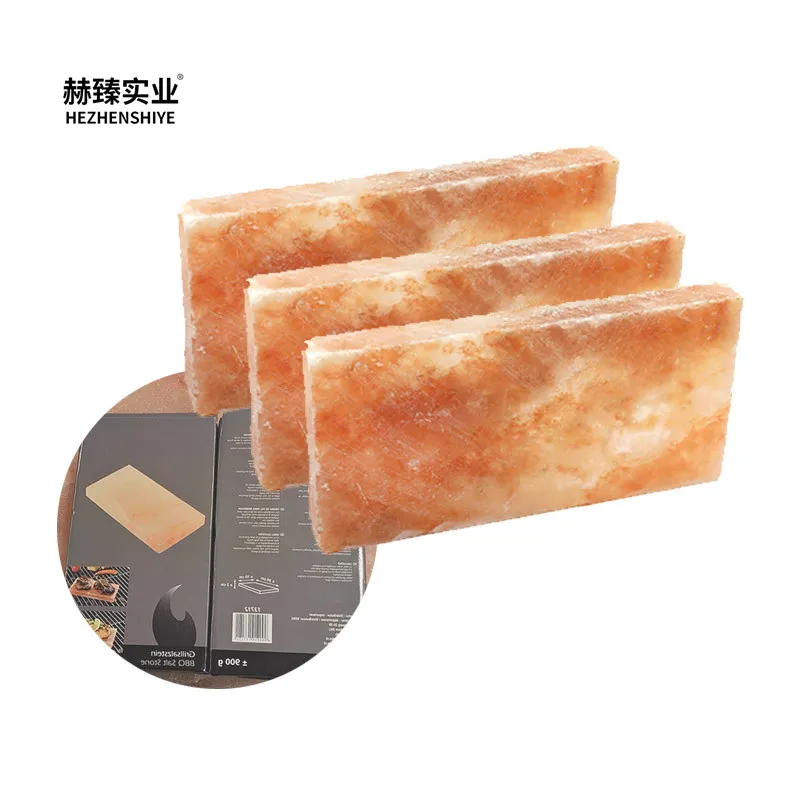

Black Tourmaline, a common variant of Tourmaline Stone, offers enhanced durability and UV resistance, making it well-suited for outdoor industrial coatings

With its deep black hue and dense crystalline structure, Black Tourmaline absorbs and scatters UV radiation, preventing coating degradation caused by prolonged sunlight exposure—such as chalking, fading, or cracking. When added to coatings for outdoor structures (e.g., bridges, pipelines, or industrial machinery), Black Tourmaline extends the coating’s service life by up to 30% compared to formulations without it. It also improves scratch resistance, as its hard crystalline particles (with a Mohs hardness of 7–7.5) reinforce the coating matrix, reducing damage from impacts or abrasive contact. Beyond functionality, Black Tourmaline adds a sleek, matte finish to coatings, making it a popular choice for applications where both performance and aesthetic appeal are priorities.

Pink Tourmaline, another distinctive variant of Tourmaline Stone, brings unique antimicrobial and thermal regulation properties to industrial coatings

Its pink hue, derived from manganese impurities, is accompanied by a subtle ability to emit far-infrared (FIR) radiation when exposed to temperature changes. In coatings for food processing facilities or healthcare equipment, this FIR emission helps inhibit the growth of bacteria (such as E. coli and Staphylococcus aureus) by disrupting microbial cell membranes, enhancing the coating’s hygienic performance. Additionally, Pink Tourmaline’s thermal regulation capability helps stabilize surface temperatures of coated substrates, reducing heat absorption in hot environments and minimizing condensation in cold conditions. This makes it ideal for coatings on refrigeration units, food storage tanks, or medical devices, where temperature control and microbial resistance are critical.

Watermelon Tourmaline, a rare and visually striking Tourmaline Stone characterized by its green outer layer and pink inner core, offers a unique blend of the properties of Black and Pink Tourmaline, with added value for specialty industrial coatings. Its dual-color structure creates a gradient effect when integrated into transparent or semi-transparent coatings, making it a preferred choice for decorative-industrial applications—such as coatings for architectural metal panels or high-end consumer appliances. Beyond aesthetics, Watermelon Tourmaline retains Tourmaline’s core benefits: it provides antistatic protection, enhances UV resistance, and exhibits mild antimicrobial activity. Its rarity also makes it suitable for high-performance, niche coatings where both functionality and a premium, distinctive appearance are required, such as in luxury automotive trim or aerospace interior components.

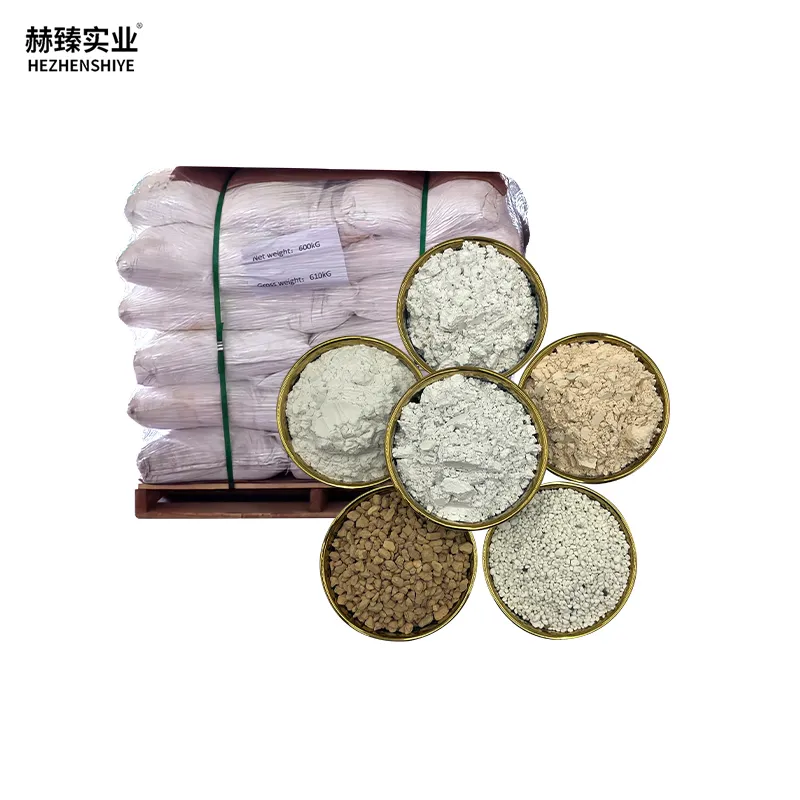

Tourmaline Stone, in all its variants, acts as a versatile foundation for industrial coating innovation, bridging the gap between performance, sustainability, and aesthetic flexibility

Unlike synthetic additives that may leach harmful chemicals over time, natural Tourmaline Stone is non-toxic and chemically stable, ensuring long-term safety for both users and the environment. Its compatibility with a wide range of coating types—including epoxy, polyurethane, and acrylic formulations—allows manufacturers to integrate it into existing production processes without major modifications. Whether used as a standalone additive or combined with other minerals, Tourmaline Stone enhances coating performance across key metrics: durability, safety, and environmental resilience.

In summary, Tourmaline and its variants—Black Tourmaline, Pink Tourmaline, Watermelon Tourmaline, and the broader category of Tourmaline Stone—have redefined the potential of industrial coating additives. Tourmaline’s multifunctional properties address critical industry needs, from antistatic protection and UV resistance to antimicrobial activity and thermal regulation, while its sustainability and cost-effectiveness align with modern manufacturing priorities. Black Tourmaline excels in outdoor durability, Pink Tourmaline enhances hygienic performance, Watermelon Tourmaline caters to specialty aesthetic-functional applications, and Tourmaline Stone serves as a reliable, natural base for diverse formulations. As the industrial coatings sector continues to prioritize high-performance, eco-friendly solutions, Tourmaline and its variants will remain at the forefront, driving innovation and setting new standards for coating functionality and versatility.

Turmalin FAQs

1. What are the primary advantages of using tourmaline in industrial coating formulations?

Tourmaline powder offers a unique combination of properties that significantly enhance coating performance. Its inherent permanent polarity generates spontaneous and permanent electric fields, which actively dissipate static charge to provide superior anti-static protection. This same mechanism helps to improve weatherability by forming a protective layer that shields the substrate from UV degradation and environmental pollutants. Furthermore, tourmaline's hardness contributes to increased abrasion resistance, extending the service life of the coated product in demanding applications.

2. How does tourmaline enhance compatibility with diverse substrates in coating systems?

The mineral structure of tourmaline allows for excellent dispersion within various polymer matrices and resin systems used for industrial coatings. Its surface characteristics can be modified to achieve strong interfacial adhesion with both metal and plastic substrates, preventing delamination or peeling. This compatibility ensures uniform film formation without compromising the mechanical properties of the coating, making it suitable for applications ranging from automotive parts to electronic housings where flexibility and adhesion are critical.

3. In what ways does tourmaline contribute to improved safety features in functional coatings?

Tourmaline's continuous emission of far-infrared radiation and negative ions helps to neutralize airborne pollutants and inhibit microbial growth on coated surfaces. This creates a safer environment in applications such as healthcare facilities or food processing plants where hygiene is paramount. The anti-static properties also reduce spark risks in explosive atmospheres, providing an additional layer of safety for equipment operating in volatile environments.

4. What role does tourmaline play in enhancing the durability of protective coatings?

When incorporated into coating formulations, tourmaline particles form a dense, interconnected network within the film that acts as a barrier against corrosive agents. This network minimizes permeability to moisture, oxygen, and chemical contaminants that typically cause coating failure. The particles also help to distribute mechanical stress across the coating surface, reducing crack propagation and maintaining structural integrity under thermal cycling or physical impact.

5. How does tourmaline address challenges related to sustainable coating development?

Tourmaline serves as a multifunctional additive that enables formulators to reduce the overall complexity of coating systems. By replacing multiple specialized additives with a single component, it helps decrease the environmental footprint of production processes. The mineral's natural origin and long-lasting performance contribute to extended maintenance cycles, reducing the frequency of reapplication and associated waste generation over the product lifecycle.