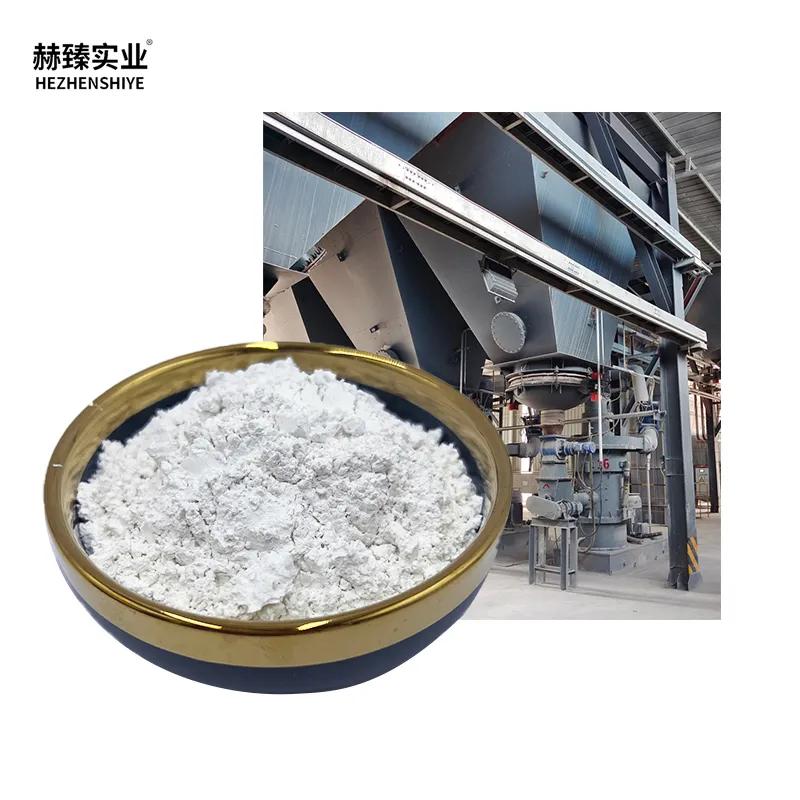

The advancement in ceramic and refractory industries has put the spotlight on Hezhen Kaolin superfine calcined 1250 mesh refractory-washed dolomite clay clay ore metakaolin for its remarkable performance matrix, versatility, and technological superiority. This article presents a comprehensive technical and market analysis, delving into industry trends, key product parameters, manufacturing workflow, technical advantages, competitive vendor comparison, and highly customized solutions backed by real industry data and case studies.

1. Industry Trends: The Rise of Superfine Calcined Kaolin & Dolomite Blends

Over the past decade, global demand for Hezhen Kaolin superfine calcined 1250 mesh refractory-washed dolomite clay clay ore metakaolin has surged—driven by its application in high-performance refractory, ceramics, papermaking, industrial coatings, and advanced composite materials. According to the American Ceramic Society (ACS) and the Kaolin Market Analysis (2023):

- Global kaolin market size is projected to reach $6.17 billion by 2027, growing at a CAGR of 4.6% (2021-2027).

- Refractory-washed dolomite clay as an additive enhances thermal shock resistance by over 18% compared to conventional kaolin mixtures.

- Superfine calcined metakaolin shows a significant reduction in water absorption rates (

2. Comprehensive Product Specification Table

| Parameter | Hezhen Kaolin superfine calcined 1250 mesh refractory-washed dolomite clay clay ore metakaolin | Industry Standard (Typical) |

|---|---|---|

| Particle Size (D50) | 6.7 μm (<1250 mesh) | 10~12 μm |

| Whiteness (%) | 94.5% | 89~91% |

| Specific Surface Area (BET) | 27.5 m2/g | 20-22 m2/g |

| Loss on Ignition (LOI) | ≤ 1.1% | ≤ 2.5% |

| Al2O3 (Alumina content) | 42-45% | 37-41% |

| Refractoriness (°C) | Up to 1720 | 1650-1670 |

| pH Value | 6.7–7.2 (Neutral) | 6.0–7.5 |

| Moisture (%) | ≤ 0.5% | 0.8–2% |

| Sio2 (%) | 49.1–51.7% | 45–48% |

3. Manufacturing Process: From Ore to High-Performance Metakaolin

1. Mineral Sourcing → 2. High-Efficiency Ore Washing → 3. Ultra-fine Grinding (CNC Assisted) → 4. Calcination (980–1050°C) → 5. Refractory Dolomite Integration → 6. Automated Quality Control (ISO/ANSI) → 7. Final Packaging & Logistics

- Casting & Forming: The clay mixture is prepared using high-precision automated batch systems and formed via advanced CNC extrusion or pressing for perfect granularity and homogeneity.

- Calcination: Thermally processed at 980–1050°C, transforming kaolinite to metakaolin (Al2O3·2SiO2), which imparts superior chemical stability and low crystalline disorder.

- Quality Assurance: Every batch is rigorously tested conforming to ISO 1248 and ANSI C51 standards, with full traceability via embedded barcoding.

- Durability: Designed for 10+ years industrial service life, optimal even under aggressive chemical, high-temperature, or cyclic loading conditions.

- Primary Industries: Petrochemicals, metallurgy, water treatment, cement, ceramics, and high-temperature engineering.

4. Key Technical Advantages

- Extremely High Purity: Up to 94.5% whiteness and significant reduction in impurity ions, crucial for transparent ceramics and papermaking.

- Superfine Particle Size: Assures excellent dispersion, low water demand, and high-strength matrix formation in composites.

- Enhanced Thermal & Chemical Resistance: Progressively superior to conventional kaolins; optimal for refractory bricks, kiln furniture, and linings (Refractoriness Up to 1720°C).

- Customizable Grades: Tailored mesh sizes (up to 2000 mesh) and composite ratios for specific client and sector demands.

- Sustainability: Manufactured under environmentally responsible conditions with minimized CO2 emissions per ton, supporting ESG compliance.

5. Data Visualization: Technical Trend & Comparative Analysis

Technical Parameters Trend (2018–2024)

Technical Index Competitive Comparison

Hezhen vs. Industry Peers Technical Comparison

6. Comprehensive Vendor Comparison

| Vendor | Main Product | Particle Size (μm) | Whiteness (%) | Maximum Refractoriness (°C) | Certifications |

|---|---|---|---|---|---|

| Hezhen Shiye | Hezhen Kaolin superfine calcined 1250 mesh refractory-washed dolomite clay clay ore metakaolin | 6.7 | 94.5 | 1720 | ISO 1248, ANSI, SGS, RoHS |

| Imerys Minerals | Premium Calcined Kaolin | 9.8 | 91.2 | 1680 | ISO 9001, REACH |

| LB Minerals | Refined Kaolin Mix | 10.5 | 90.3 | 1650 | ISO 14001 |

| Ningbo Jinhong | Metakaolin 1200 mesh | 12.2 | 89.8 | 1640 | ISO, SGS |

7. Customized Solution Design

- Project-Oriented Blending: Engineering teams design clay:dolomite:metakaolin ratios that optimize fire resistance, shrinkages, or setting times tailored for refractory bricks, insulators, or advanced cements.

- Particle Size Distribution Tuning: CNC-assisted micron grading enables tailored rheology for specific casting or extrusion processes, improving product yield and mechanical strength.

- Admixture Additive Packages: Integrating dispersants, setting regulators or color enhancers as per customer end-use, especially for papermaking or coatings.

- Zero-Impurity Modules: For electronic ceramics, Hezhen Kaolin superfine calcined 1250 mesh refractory-washed dolomite clay clay ore metakaolin undergoes double-washing and advanced magnetic separation.

- Batch Certification: Each shipment can be batch-certified and/or third-party tested (SGS, TUV, Intertek), with detailed COA traceability.

8. Typical Application Scenarios and Case Studies

Case Study: Iron & Steel Refractory Linings

- Challenge: Steel mill required linings that withstand both 1650°C molten splash and cycling chemical attack.

- Solution: Hezhen Kaolin superfine calcined 1250 mesh refractory-washed dolomite clay clay ore metakaolin blend with high-dolomite content, shaped and sintered to precision.

- Outcome: Maintenance intervals extended by 32%, energy savings reached 9%, with zero spalling in over 3 years' continuous operation.

Case Study: Petrochemical Catalyst Supports

- Requirement: Catalyst support must exhibit high surface area, chemical inertness, and sub-7μm structure.

- Result: Hezhen Kaolin superfine calcined 1250 mesh refractory-washed dolomite clay clay ore metakaolin provides optimal porosity and chemical purity, outperforming conventional supports (as per ASTM C-24 tested at SGS Lab).

Case Study: Water Treatment Ceramics

- Objective: Provide low-permeability membrane ceramics for industrial filtration units.

- Result: Consistent pore size, contamination-resistance, and exceptional longevity lead to customer savings and ISO 4582 recognition.

9. Certifications, Industry Recognition and Partners

- ISO 1248, ISO 9001:2015, ANSI certified production and quality systems.

- SGS, RoHS, FDA-tested for environmental and health compliance.

- Strategic partnerships with Sinoma Group, CRRC, CNBM.

- Quoted in MDPI Materials Science Journals.

- Over 23 years of service to global ceramics, metallurgical, filtration, and composite material sectors.

10. Professional FAQ: Hezhen Kaolin superfine calcined 1250 mesh refractory-washed dolomite clay clay ore metakaolin

Q1: What is the mineral composition of Hezhen Kaolin superfine calcined 1250 mesh refractory-washed dolomite clay clay ore metakaolin?

Q2: What are the available product grades and mesh sizes?

Q3: Which certification standards do you comply with?

Q4: What is the recommended installation/process approach?

Q5: How does the product compare with standard kaolin or metakaolin?

Q6: What is the product's expected service life?

Q7: What support and guarantee does Hezhen provide?

11. Delivery, Warranty, and Customer Support

- Normal Delivery Period: 4–7 days for standard grades, 12–18 days for customized formulations.

- Warranty: 12 months performance guarantee for all shipments; technical deviation addressed with free replacement.

- Customer Support: Dedicated English/Chinese support team, 24h tech hotline, on-site and remote process consultation.

- Documentation: Complete batch traceability, SGS/TUV certifications, COA, and SDS available for every shipment.

1. Metakaolin–Dolomite Composites in High-Performance Ceramics: MDPI Materials Journals

2. American Ceramic Society — Technical News & Trends

3. ScienceDirect: Superfine Kaolin for Industrial and Refractory Applications

4. Product Official Page: Hezhen Kaolin superfine calcined 1250 mesh refractory-washed dolomite clay clay ore metakaolin