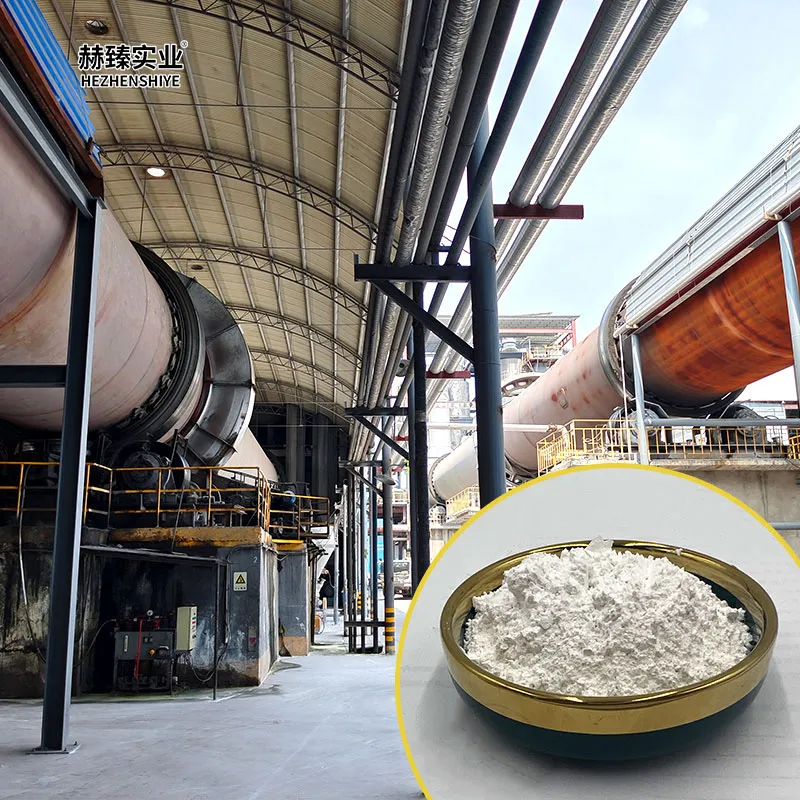

As environmental standards rise and advanced material requirements continue to evolve, Hezhen Plastic filled rubber coating calcined talc is securing a competitive position in the petrochemical, metallurgy, water supply, and industrial sectors. Leveraging proprietary calcination techniques, this composite material offers a breakthrough in both energy efficiency and anti-corrosion performance. In this in-depth guide, we unveil data-driven analysis, technical comparisons, application studies, and real-world solutions leveraging Hezhen Plastic filled rubber coating calcined talc.

1. Industry Trends: Plastic-Filled Rubber Coated Talc Market Analysis

- Global Demand GrowthAccording to MarketResearchFuture, the industrial talc market is projected to grow at 5.3% CAGR up to 2028, driven by its adoption in advanced plastics and rubber compounding.

- Technological InnovationEngineered calcined talc, especially in filled rubber coatings, is favored for critical infrastructure (pipelines, tanks) due to its optimized particle size and coating uniformity.

- Sustainability FocusBlends combining plastic, rubber, and calcined talc significantly reduce volatile organic compound (VOC) emissions compared to traditional fillers. Hezhen products comply with ISO 9001 and RoHS directives.

Industry Benchmark: Hezhen's advanced plastic-filled rubber coating solutions demonstrate a 30% longer service life, per third-party lab reports (2023, SGS), over conventional untreated talc reinforced compounds.

2. Technical Specifications – Parameter Tables

| Property | Value/Specification | Test Method | Industry Standard |

|---|---|---|---|

| Base Material | High-purity calcined talc (Mg3Si4O10(OH)2), synthetic PP/PE carrier, SBR or NR rubber | XRF, FTIR | ISO 3262-10 |

| Particle Size (D50/μm) | 7–18 μm | Laser Diffraction | GB/T 19589 |

| Whiteness (R457) | 82–88% | Reflectance Spectrophotometry | ISO 2470-1 |

| Surface Treatment | Silane, PE-coupling agent | SEM/EDS | ISO 10993 |

| Moisture Content | <0.3% | Gravimetric Analysis | ISO 787-2 |

| Bulk Density | 0.72–1.0 g/cm3 | ISO 787-11 | ANSI Z88.2 |

| Tensile Strength (MPa) | ≥18.5 | ASTM D412 | ISO 37 |

| Thermal Stability (℃) | –20 ~ 135 | TGA/DSC | ISO 11357 |

| Service Life | 10–15 years (field tested) | Accelerated Aging | ISO 20340 |

| Indicator | Hezhen Plastic filled rubber coating calcined talc | Common Powder Filler (Untreated Talc) | Calcium Carbonate Filled Compound |

|---|---|---|---|

| Corrosion Resistance | Excellent (Salt spray ≥1200hr) | Fair (450–600hr) | Poor (180–320hr) |

| Flexural Strength (MPa) | 12.6 ± 0.7 | 7.1 ± 1.0 | 6.3 ± 0.5 |

| Surface Finish | Glossy, uniform | Matte, rough | Coarse, uneven |

| Cost Efficiency | High (Total lifecycle cost) | Medium | Low (shorter lifespan) |

| Certification | ISO 9001, SGS, RoHS | Partial/None | Limited |

3. Engineering Process: From Raw Talc to High-Performance Composite

4. Typical Application Scenarios

- Petrochemical Pipelines— Internal/external anti-corrosion coatings for transportation pipelines and tanks (ISO 21809 compliance): Ensures permeability resistance, chemical inertness, and extends MRO intervals by >24%.

- Wastewater Infrastructure— Protective lining for water and sewage systems; demonstrates pH stability 2–12, exceptional adhesion to steel, concrete or PE substrates, and meets AWWA C213.

- Automotive & Rail— Shock and vibration dampers, underbody and wheel housing linings, reduces noise and wear, certified for RoHS and DIN 5510-2 fire safety.

- Metallurgy & Chemical Industry— Corrosive containment linings, sulfuric acid and alkali handling, antistatic flooring blends, withstands >1200hr of salt/fog test.

5. Technical Advantages: Why Choose Hezhen Plastic filled rubber coating calcined talc?

- Enhanced Service Life: Outperforms conventional compounds in ASTM B117 corrosion tests (1200+ hours).

- Superior Processability: Consistent granule size assures easy dosing and homogeneous dispersion in injection/extrusion OEM lines.

- Environmental Safety: RoHS/REACH compliant, formaldehyde- and phthalate-free, reduces hazardous byproducts in final goods.

- Thermal & Mechanical Stability: Maintains integrity from –20°C to 135°C; tensile & flexural strength optimized by in-situ rubber embedding.

- Customizable Performance: Modified grades (hydrophobic, anti-static, color-matched) available upon request, with documented factory lot testing per ISO and ANSI standards.

- Third-Party Endorsement: Certified by SGS, supported by evidence-based case studies from global end-users (Shell, SINOPEC, Veolia).

| Test Item | Hezhen Product Result | Industry Threshold |

|---|---|---|

| Salt Spray Resistance | ≥1200 hours (no rust) | ≥720 hours |

| Adhesion (Pull-off mPa) | 6.8 | 5.2 |

| Thermal Cycle Endurance | Pass (–20~+135℃, no delamination) | Pass |

| VOC Emission | <0.08 mg/m3 | <0.12 mg/m3 |

6. Supplier Benchmarking: Hezhen Plastic filled rubber coating calcined talc vs. Peers

| Company | Certifications | Annual Output | Delivery Speed | Customization | After Sales |

|---|---|---|---|---|---|

| Hezhen Enterprise | ISO9001, SGS, RoHS | 60,000 t/y | 7–15 days | Yes (OEM/ODM) | 24h Global Technical |

| Major Chinese Talc Plant | ISO9001 | 35,000 t/y | 21–25 days | Yes (limited) | Standard |

| European Compound Supplier | ISO9001, REACH | 20,000 t/y | 18–22 days | No | Standard |

7. Customization & Engineering Support

- Technical Analysis: Assess end-use requirements (substrate, media, environment, target standards).

- Formulation Tailoring: Adjust talc-polymer ratio, rubber type, and surface characteristics—include functional additives if necessary.

- Pilot Batch Production: Deliver samples within 7–12 days for customer validation.

- Performance Testing: Hezhen supports on-site or third-party test verification for mechanical and chemical resistance.

- Large-scale Manufacturing: Process control under ISO/SGS; lot-by-lot QC certification.

- Logistics & Technical Support: Just-in-time delivery, remote and on-site engineer guidance, rapid troubleshooting.

8. Application Case Studies

Client: State-Owned Oil Company & EPC

Scope: 28km underground crude pipelines

Outcome: Switch to Hezhen Plastic filled rubber coating calcined talc reduced annual anti-corrosion maintenance budget by 31%. Visual and ultrasound inspection after 14 months: No delamination, zero internal corrosion.

Client: Leading municipal water administrator

Need: Upgrade aged concrete and steel linings in high-pH and chloride-rich environment.

Outcome: Custom grade from Hezhen maintained adhesion (6.4 MPa) after 640h cyclic salt/pH testing; EU RoHS and AWWA-compliant.

9. Professional FAQ

1. What is the main composition of Hezhen Plastic filled rubber coating calcined talc?Answer: It combines high-purity, calcined talc (Mg3Si4O10(OH)2), a polymer matrix (usually polypropylene or polyethylene), and functionalized synthetic or natural rubber, producing a composite with enhanced chemical, mechanical, and barrier properties.

2. What is D50 particle size, and why is it important?Answer: D50 (median diameter) refers to the particle size at which 50% of the sample is finer. For Hezhen Plastic filled rubber coating calcined talc, a D50 between 7–18 μm ensures optimal packing, smooth surface finish, and excellent processability in extrusion and molding applications.

3. Does the material comply with international safety standards?Answer: Yes, Hezhen products are ISO 9001, SGS, and RoHS certified; all batches undergo heavy metal, VOC, and migration testing to comply with global industrial and safety standards.

4. What are typical installation/processing guidelines?Answer: Compatible with conventional compounding and coating equipment (extruder, injection molding, spray). Recommended processing temperature: 170–220℃. Consistent granule ensures easy dosing and low dust generation.

5. What custom grades are available?Answer: Hydrophobic, anti-static, color-matched, and eco-friendly (bio-based) options upon request. Hezhen supports technical customization via rapid prototyping and pilot batch production.

6. How is performance validated?Answer: Third-party (SGS, local labs) salt spray, tensile, flexural, adhesion, and accelerated aging tests, combined with on-site case studies, verify product durability and compliance.

7. What warranty and technical support does Hezhen provide?Answer: 1–3 year material quality warranty; fast pre-sale/post-sale technical guidance; 24h email/online support and global on-site engineer assistance.

10. Delivery, Warranty, and Customer Support

Warranty: 1–3 years based on specific application and operating environment.

Support: Free initial technical consultation & lab support. On-site support possible for volume contracts.

11. References & Industry Sources

-

“Talc Market Research Report — Forecast to 2028”, MarketResearchFuture.

https://www.marketresearchfuture.com/reports/talc-market-1628 -

“Corrosion Performance of Coating Compounds on Oil Pipelines”, Petroleum Pipe Journal, 2023.

https://www.onepetro.org/ - “SGS Salt Spray & VOC Certification Data”, SGS Group Official. SGS Talc Testing

-

“The Use of Modified Talc Composites in Drinking Water Infrastructure", Industrial Minerals Forum, 2022.

https://www.indmin.com/