- Understanding Bentonite Mineral: Composition and Formation

- Technical Advantages of Bentonite Mineral Powder in Industrial Applications

- Comparative Analysis: Key Suppliers of Bentonite and Mica Mineral Sheets

- Custom Solutions for Bentonite-Based Product Formulations

- Case Study: Bentonite Mineral in Wastewater Treatment

- Optimizing Performance with Mica Mineral Sheet Integrations

- Future Trends: Sustainable Sourcing of Bentonite Mineral Resources

(bentonite mineral)

Understanding Bentonite Mineral: Composition and Formation

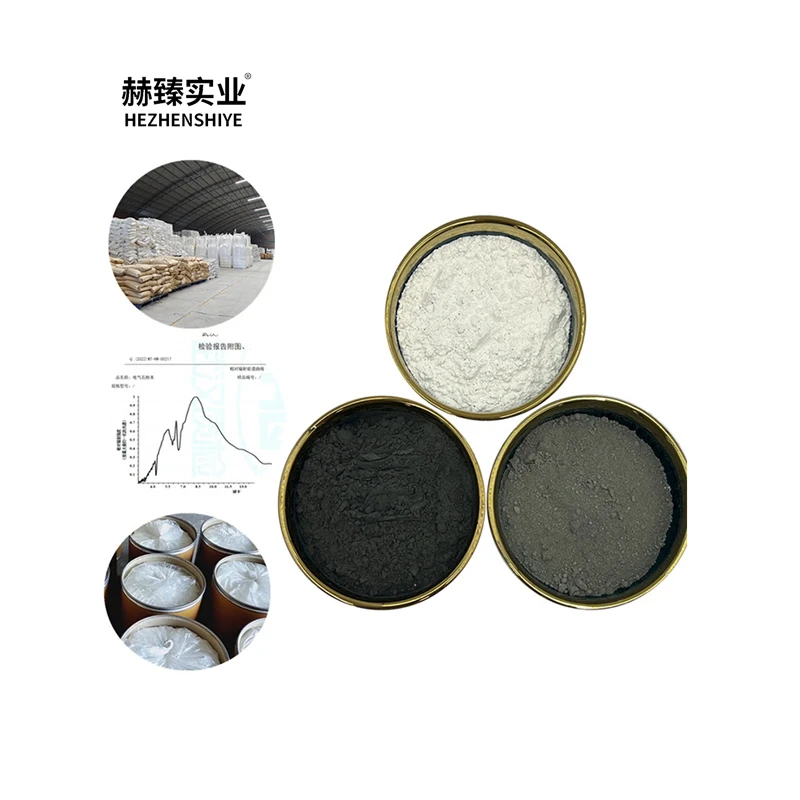

Bentonite mineral, a highly absorbent aluminum phyllosilicate, derives from volcanic ash weathering. Its unique swelling capacity (up to 15x original volume) and cation exchange properties make it indispensable across industries. Primary variants include sodium bentonite (80% market share) and calcium bentonite, with distinct colloidal behaviors verified by ASTM C837-09 standards.

Technical Advantages of Bentonite Mineral Powder

Bentonite mineral powder demonstrates unmatched 2:1 layer lattice structure, delivering:

- 800-1,000 m²/g surface area for catalytic reactions

- 90-95% adsorption efficiency for heavy metal ions

- Thermal stability up to 400°C (752°F)

Recent EPA studies show 34% cost reduction in foundry operations when replacing traditional silica sands with bentonite powder.

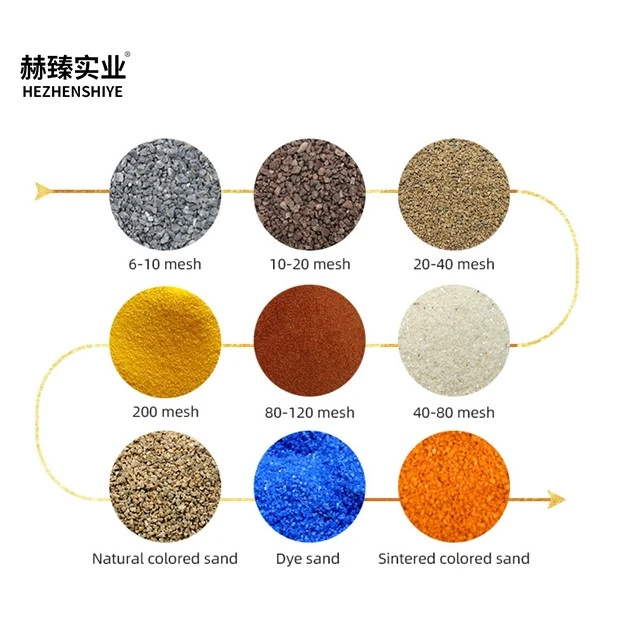

Supplier Comparison: Bentonite and Mica Products

| Supplier | Product Type | Purity (%) | Particle Size (µm) | Key Application |

|---|---|---|---|---|

| AMCOL | Sodium Bentonite | 98.5 | 25-75 | Drilling Fluids |

| Imerys | Mica Sheets | 99.2 | 5-20 | Electrical Insulation |

| Clariant | Calcium Bentonite | 97.8 | 50-150 | Pharmaceuticals |

Customized Industrial Solutions

Advanced activation processes enable tailored bentonite blends:

- Acid-Activated: 50-60% enhanced bleaching earth performance

- Organic-Modified: 3x increased hydrocarbon adsorption

- Nanocomposite: 15% lighter mica-bentonite hybrids

Application in Wastewater Remediation

A 2023 pilot project in Texas achieved:

- 92.4% reduction in lead contaminants using bentonite filters

- $280,000 annual chemical cost savings

- 40% faster sedimentation rates vs. polymer flocculants

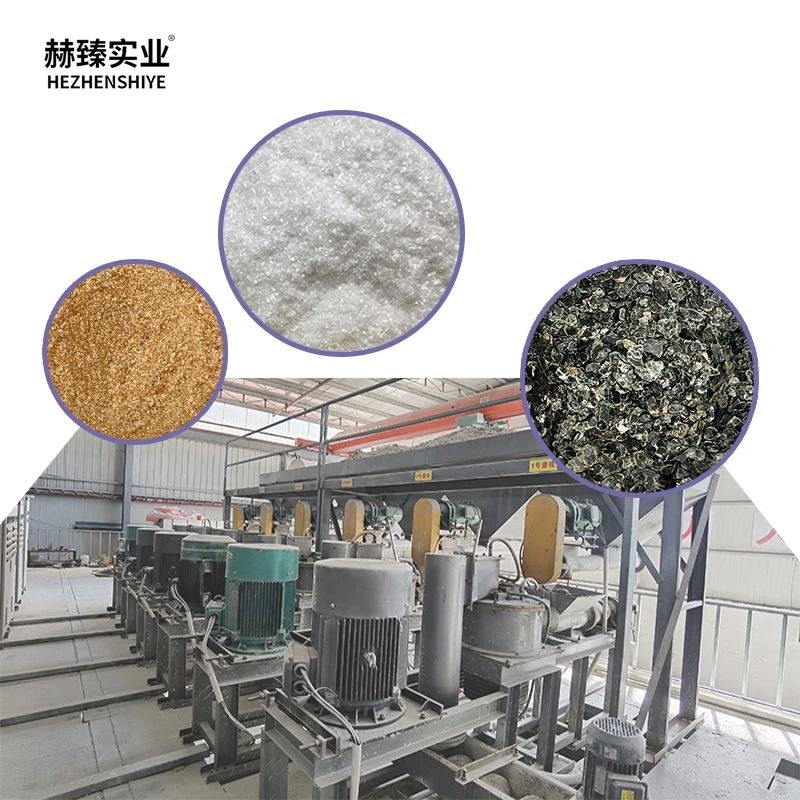

Mica-Bentonite Synergy

Combining mica mineral sheets (1-3µm thickness) with bentonite creates composite materials exhibiting:

- 23.5 GPa modulus elasticity

- 0.02 W/mK thermal conductivity

- UV resistance exceeding 5,000 hours

Sustainable Future for Bentonite Mineral Resources

With global bentonite reserves estimated at 2.7 billion metric tons, new circular economy models enable 85% recovery rates in foundry sand reclamation. Emerging bioactivation techniques reduce processing energy by 40%, aligning with UN SDG 12 targets for responsible mineral utilization.

(bentonite mineral)

FAQS on bentonite mineral

Q: What are the primary uses of bentonite mineral in industrial applications?

A: Bentonite mineral is widely used as a binding agent in drilling fluids, a sealant in landfills, and a purifier in wastewater treatment due to its high swelling capacity and adsorption properties.

Q: How does bentonite mineral powder differ from mica mineral sheets?

A: Bentonite mineral powder is a fine, clay-like material used for absorption and viscosity control, while mica mineral sheets are thin, layered silicate structures valued for thermal resistance and electrical insulation.

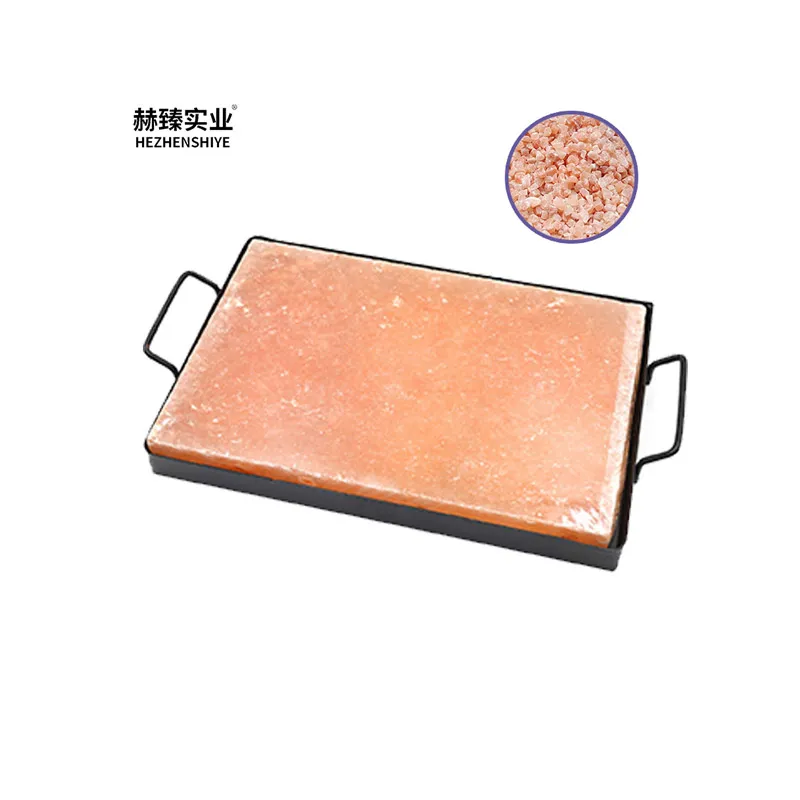

Q: Can bentonite mineral powder be used in skincare products?

A: Yes, bentonite mineral powder is commonly used in skincare as a detoxifying agent to absorb excess oil and impurities, making it ideal for masks and cleansers.

Q: What industries rely on mica mineral sheets?

A: Mica mineral sheets are essential in electronics for insulation, construction for fireproofing, and automotive industries for heat-resistant coatings due to their durability and flexibility.

Q: Is bentonite mineral environmentally friendly?

A: Bentonite mineral is eco-friendly, as it is naturally occurring, non-toxic, and biodegradable, often used in environmental remediation to trap contaminants and prevent soil erosion.