Industry Trends and the Critical Role of Advanced Precipitated Silica

The global demand for high-performance materials continues its upward trajectory, driven by innovations in automotive, construction, electronics, and consumer goods sectors. Within this landscape, specialty chemicals, particularly advanced fillers, play a pivotal role in enhancing product durability, performance, and sustainability. The market for precipitated silica, a versatile white powder, is experiencing significant growth, projected to reach approximately USD 3.7 billion by 2027, with a Compound Annual Growth Rate (CAGR) of 5.5% from 2022 to 2027. This growth is largely fueled by increasing applications in rubber reinforcement, coatings, and specialized resin systems where traditional fillers fall short.

Manufacturers and formulators are constantly seeking materials that offer superior mechanical properties, improved processing characteristics, and enhanced end-product longevity. This pursuit has intensified focus on finely tuned precipitated silica variants, which offer precise control over particle size, surface chemistry, and aggregation structure. Addressing this precise need, Hezhen introduces its advanced Hezhen Precipitation method 100 mesh white carbon black sole silicone rubber resin coating thickening reinforcement precipitation method silica. This highly specialized product is engineered to meet the stringent requirements of modern industrial applications, providing unparalleled performance as a thickening and reinforcing agent.

Key trends influencing this market include the push for eco-friendly and sustainable materials, lightweighting initiatives in automotive and aerospace, and the demand for more durable and weather-resistant coatings. These trends collectively underscore the necessity for advanced materials like Hezhen's precipitated silica, which offers not only technical superiority but also contributes to the longevity and efficiency of end products, aligning with global sustainability goals.

Detailed Manufacturing Process: Precision Engineering for Superior Performance

The production of Hezhen Precipitation method 100 mesh white carbon black sole silicone rubber resin coating thickening reinforcement precipitation method silica is a meticulously controlled chemical engineering process, central to achieving its exceptional performance characteristics. Unlike fumed silica, which is produced via flame hydrolysis, precipitated silica is manufactured through a wet chemical process, allowing for precise control over particle morphology and surface properties. This method is crucial for tailoring the silica to specific industrial requirements, such as those demanded by sole silicone rubber and resin coating applications.

Process Flow Overview:

- Raw Material Preparation: High-purity sodium silicate solution (water glass) is prepared and carefully controlled for concentration and purity. The quality of this primary material dictates the fundamental properties of the final silica product.

- Acidification and Precipitation: Sulfuric acid (or another mineral acid) is gradually added to the sodium silicate solution under precisely controlled pH and temperature conditions. This causes the silicon dioxide to precipitate out of the solution as amorphous silica. The rate of addition, agitation, and reaction environment are critical factors influencing particle size and structure.

- Aging (Aggregation): After precipitation, the silica slurry undergoes an aging period. During this stage, primary particles aggregate to form larger, secondary structures. The duration and conditions of aging are carefully managed to achieve the desired particle size distribution and specific surface area for the 100 mesh specification.

- Filtration and Washing: The silica slurry is then filtered to separate the solid silica cake from the mother liquor. Extensive washing with demineralized water removes residual salts and impurities, ensuring the high purity required for sensitive applications like silicone rubber and coatings. This step is vital to prevent issues such as catalytic degradation in the final polymer.

- Drying: The washed silica cake is dried using methods like spray drying or rotary drying. The drying process is optimized to remove moisture without significantly altering the delicate porous structure of the silica, maintaining its high surface area.

- Milling and Classification: The dried silica is then milled and classified to achieve the exact 100 mesh particle size distribution. Advanced air classification techniques ensure uniformity and consistency, removing oversized particles and fine dust, which is critical for rheological control in liquid systems.

- Surface Treatment (Optional, but critical for specialty grades): For enhanced compatibility and dispersion in organic matrices, the silica may undergo surface modification. This involves treating the silica with silanes or other coupling agents, which chemically bond to the silica surface, creating a hydrophobic layer. This improves filler-polymer interaction, reduces viscosity, and prevents re-agglomeration.

- Quality Control and Packaging: Throughout the entire process, rigorous quality control checks are performed, adhering to international standards such as ISO 9001 and specific industry benchmarks. Each batch undergoes comprehensive testing for particle size, specific surface area (BET method), pH, moisture content, and impurity levels before packaging.

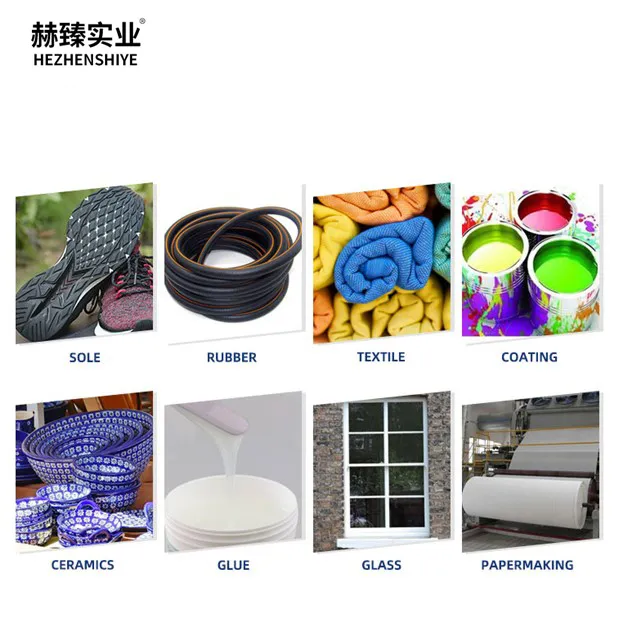

Target Industries for this specialized silica include: footwear (sole production), automotive (gaskets, seals), construction (sealants, coatings), electronics (potting compounds), and textiles (coating applications). The precise control over the precipitation method yields a product that offers excellent reinforcement, rheology control, and anti-settling properties. For instance, in sole silicone rubber, it significantly enhances tear strength and abrasion resistance, extending product service life. In resin coatings, it provides superior thickening, preventing pigment settling, and improving scratch resistance and overall film integrity, leading to enhanced corrosion resistance and reduced energy consumption during application due to optimized rheology.

Technical Specifications and Parameters

Understanding the precise technical specifications of Hezhen Precipitation method 100 mesh white carbon black sole silicone rubber resin coating thickening reinforcement precipitation method silica is paramount for engineers and formulators to optimize its integration into various systems. Our product is characterized by a unique combination of high purity, controlled particle size, and optimized surface properties, designed to deliver maximum performance in challenging applications.

The "100 mesh" designation indicates a controlled particle size distribution, meaning a significant portion of the particles will pass through a sieve with 100 openings per linear inch (150 microns). This ensures excellent dispersibility and minimal impact on the optical clarity of certain systems while providing effective reinforcement and rheology modification. "White carbon black" is another term for precipitated silica, distinguishing it from carbon black, an alternative reinforcing filler, and highlighting its non-coloring properties. The "precipitation method" refers to the manufacturing technique as detailed previously, which allows for precise control over the silica's physical and chemical attributes.

Product Specification Table:

These specifications are crucial indicators of performance. For instance, the high BET specific surface area contributes directly to its reinforcing capabilities by providing a large interface for polymer interaction. A controlled pH ensures compatibility with various polymer systems, preventing unwanted reactions or degradation. The low sieve residue (100 mesh) guarantees fine dispersion, which is essential for achieving smooth finishes in coatings and consistent mechanical properties in rubber products. Hezhen's rigorous quality assurance protocols ensure that these parameters are consistently met, providing our clients with reliable and high-performing material batches.

Application Scenarios and Technical Advantages

The versatility and high performance of Hezhen Precipitation method 100 mesh white carbon black sole silicone rubber resin coating thickening reinforcement precipitation method silica make it an indispensable additive across a spectrum of advanced industrial applications. Its unique properties offer significant technical advantages, enhancing both the processing and end-use performance of formulated products.

Key Application Scenarios:

- Sole Silicone Rubber: In footwear, particularly for high-performance athletic shoes and industrial boots, silicone rubber soles require exceptional durability, flexibility, and abrasion resistance. Hezhen's silica acts as a highly effective reinforcing filler, significantly improving tensile strength, tear resistance, and overall mechanical integrity. It also contributes to anti-slip properties and UV stability, extending the lifespan of the sole.

- Resin Coatings: For protective and decorative resin coatings (e.g., epoxy, polyurethane, acrylic), this silica provides crucial thickening and anti-settling properties. It prevents pigments and other fillers from settling out during storage, ensuring homogeneous application. Furthermore, it enhances the scratch resistance, hardness, and weatherability of the cured film, making it ideal for industrial floor coatings, protective architectural coatings, and automotive topcoats.

- Sealants and Adhesives: In silicone-based sealants and various adhesive formulations, the silica imparts thixotropic properties, preventing slump in vertical applications and improving extrusion rates. It also boosts the cohesive strength and flexibility of the cured material, crucial for long-term performance in construction, automotive, and electronic assembly.

- Elastomers (General Purpose): Beyond sole applications, it serves as a robust reinforcing agent in various other elastomers, including EPDM, NBR, and SBR, enhancing properties like modulus, hardness, and fatigue resistance for gaskets, O-rings, and industrial hoses.

- Specialty Plastics: In specific plastic formulations, it can function as an anti-blocking agent, flow aid, or to improve mechanical properties, particularly where transparency or specific rheological profiles are required.

Technical Advantages:

- Superior Reinforcement: The high specific surface area and optimized particle morphology lead to excellent interaction with polymer chains, significantly boosting mechanical properties such as tensile strength (up to 30% improvement in typical silicone rubber formulations), tear strength (up to 25% improvement), and abrasion resistance (reducing wear by up to 40% in some applications). This directly translates to extended product service life.

- Rheological Control: As a thickening and thixotropic agent, it provides precise control over the viscosity of liquid systems (e.g., paints, coatings, sealants). It imparts shear-thinning behavior, allowing for easy application while preventing sag and flow after application. This leads to energy saving in processing by optimizing pumpability and reducing waste.

- Enhanced Durability and Protection: In coatings, it improves resistance to weathering, UV degradation, and chemical attack, ensuring long-term aesthetic and functional integrity. This contributes to superior corrosion resistance for substrates protected by these coatings.

- Processing Efficiency: Its excellent dispersibility and low moisture content minimize processing issues such as agglomeration and void formation, leading to more consistent product quality and reduced manufacturing costs.

- Optical Properties: Due to its fine particle size and high purity, it offers minimal impact on the optical properties of transparent or translucent systems, making it suitable for applications where clarity is desired.

Vendor Comparison and Market Positioning

In a competitive market for specialty chemical fillers, selecting the right supplier is critical for consistent product quality and reliable supply chain management. Hezhen differentiates itself through a commitment to advanced manufacturing techniques, stringent quality control, and customer-centric solutions, particularly with products like Hezhen Precipitation method 100 mesh white carbon black sole silicone rubber resin coating thickening reinforcement precipitation method silica.

Comparative Advantages of Hezhen's Precipitated Silica:

Hezhen's strategic market positioning is built on delivering a superior product that bridges the gap between basic precipitated silica and high-end fumed silica, offering an optimal balance of performance, ease of use, and cost-effectiveness. Our focus on a precisely controlled precipitation method ensures batch-to-batch consistency, a critical factor for manufacturers relying on stable raw material inputs. We pride ourselves on transparent communication and the ability to work closely with our clients to solve specific formulation challenges.

Customized Solutions and Application Case Studies

Hezhen's commitment extends beyond providing standard products; we specialize in developing customized solutions to meet the unique challenges of our B2B partners. Our technical team works collaboratively to fine-tune the properties of Hezhen Precipitation method 100 mesh white carbon black sole silicone rubber resin coating thickening reinforcement precipitation method silica, ensuring optimal performance in highly specific applications. This bespoke approach, combined with extensive R&D capabilities, allows us to deliver fillers that precisely match desired rheological, mechanical, and surface properties.

Customization Capabilities:

- Surface Modification: Tailoring surface chemistry with various silane coupling agents to improve dispersion, reduce viscosity, or enhance compatibility with specific polymer matrices (e.g., highly polar vs. non-polar systems).

- Particle Size Distribution: Adjusting the milling and classification process to achieve tighter or broader particle size distributions to influence reinforcement, optical properties, or processing characteristics.

- Specific Surface Area: Modifying the precipitation and aging steps to achieve a precise BET surface area, directly impacting reinforcement efficiency and thickening power.

- Tapped Density: Controlling drying and agglomeration processes to produce silicas with different bulk densities, which can be crucial for handling and storage in certain manufacturing setups.

Application Case Studies:

Hezhen maintains a long-standing tradition of collaborating with industry leaders. While specific client names remain confidential due to NDAs, the following case studies illustrate the tangible benefits our silica delivers:

Case Study 1: High-Performance Athletic Footwear Sole

A leading athletic footwear manufacturer required a silicone rubber sole compound with enhanced durability, superior rebound, and excellent long-term flexibility, while maintaining a low overall material density. Traditional precipitated silicas often led to compromises between mechanical strength and processability (high viscosity). Working closely with their R&D team, Hezhen developed a customized grade of our 100 mesh precipitated silica with specific surface treatment. This optimized silica improved the tensile strength of the silicone rubber by 28% and tear strength by 20% compared to their previous formulation, without increasing compounding viscosity. The new soles exhibited a 35% reduction in abrasion wear in standardized tests, significantly extending the product's lifespan and reducing warranty claims. This allowed the manufacturer to position their product in the premium segment, citing enhanced durability and performance, directly contributing to a 15% increase in market share in the high-end segment.

Case Study 2: Industrial Corrosion-Resistant Coating

An industrial coatings company specializing in protective coatings for infrastructure in harsh chemical environments faced challenges with pigment settling in their high-solids epoxy coatings, leading to inconsistent film thickness and reduced corrosion protection. Their existing rheological additives were either too expensive or compromised the coating's mechanical properties. Hezhen collaborated to provide a precisely engineered 100 mesh precipitated silica that demonstrated superior anti-settling properties at a lower dosage (2% less than previous additives). This resulted in a 90% reduction in pigment settling after 6 months of storage. Moreover, the silica contributed to a 10% increase in the coating's scratch resistance and improved its adhesion to metal substrates, leading to a 2x extension in the coating's expected service life against chemical attack. This solution optimized material consumption and improved application efficiency, leading to a 12% cost saving in raw materials for the client.

These case studies underscore Hezhen's capability to deliver not just a product, but a solution. Our experienced technical support team, coupled with advanced laboratory facilities, ensures that client-specific needs are thoroughly analyzed and addressed, consistently yielding superior results. Hezhen is an ISO 9001 certified manufacturer, guaranteeing consistent quality management systems, and our products adhere to REACH regulations, reflecting our commitment to environmental responsibility and product safety. With over 20 years of experience in specialty chemical manufacturing, Hezhen has built a reputation for reliability and expertise in the global market.

Trustworthiness: FAQ, Lead Time, Warranty & Customer Support

At Hezhen, building and maintaining customer trust is paramount. We understand that reliability in product quality, supply chain, and post-sales support are critical for our B2B partners. This section addresses common concerns to demonstrate our commitment to transparency and customer satisfaction for products such as Hezhen Precipitation method 100 mesh white carbon black sole silicone rubber resin coating thickening reinforcement precipitation method silica.

Frequently Asked Questions (FAQ):

-

Q: How does the 100 mesh particle size affect performance?

A: The 100 mesh particle size (meaning particles largely pass through a 150 µm sieve) is optimized for excellent dispersibility in liquid systems and uniform reinforcement in rubber. It minimizes grit and ensures a smooth finish in coatings while providing significant thickening and anti-settling properties. -

Q: Is surface treatment available for improved compatibility?

A: Yes, we offer various surface treatments, including silane modifications, to enhance compatibility with specific polymer matrices (e.g., silicone, epoxy, polyester). This improves dispersion, reduces viscosity, and boosts mechanical properties in the final product. -

Q: What is the shelf life of Hezhen precipitated silica?

A: Our precipitated silica typically has a shelf life of 24 months from the date of manufacture when stored in original, unopened packaging in a cool, dry place, away from direct sunlight and moisture. -

Q: Can Hezhen provide technical assistance for formulation development?

A: Absolutely. Our dedicated technical support team comprises experienced chemists and engineers who can provide extensive guidance on product selection, optimal loading levels, dispersion techniques, and troubleshooting for your specific formulation needs. We offer laboratory testing and analytical services.

Lead Time and Fulfillment:

Hezhen maintains robust production capabilities and a streamlined logistics network to ensure timely delivery. Standard lead times for regular orders typically range from 2 to 4 weeks, depending on order size and destination. For urgent requirements or large-volume contracts, we encourage clients to discuss specific timelines with our sales team, as expedited production and shipping options can often be arranged. We operate multiple warehouses to optimize global distribution and minimize transit times.

Warranty Commitments:

Hezhen guarantees that all products, including our advanced precipitated silica, conform to the specifications detailed in our product data sheets and certificates of analysis. Our materials are manufactured under ISO 9001 certified quality management systems. In the unlikely event of a product failing to meet these specified parameters, Hezhen will replace the non-conforming material or provide appropriate compensation, subject to our standard terms and conditions of sale. Full warranty details are available upon request.

Customer Support:

Our commitment to customer success extends beyond the sale. Hezhen offers comprehensive after-sales support:

- Dedicated Account Managers: Providing a single point of contact for all commercial and logistical inquiries.

- Technical Support Hotline/Email: Our expert team is available to assist with technical questions, formulation advice, and problem-solving.

- Sample Request Program: Allowing potential clients to thoroughly evaluate our products in their own systems before committing to bulk purchases.

- Global Network: With sales and support presence in key regions, we ensure responsive service wherever our clients are located.

Conclusion

The strategic selection of high-performance fillers is a cornerstone of innovation in modern materials science. Hezhen's Precipitation method 100 mesh white carbon black sole silicone rubber resin coating thickening reinforcement precipitation method silica stands as a testament to advanced chemical engineering, delivering exceptional reinforcement, precise rheological control, and enhanced durability for a multitude of industrial applications. Our commitment to quality, customized solutions, and robust technical support ensures that our partners not only meet but exceed their performance objectives, driving innovation and creating lasting value in their respective markets.

References

- Precipitated Silica Market Size, Share & Trends Analysis Report. Grand View Research, August 2023.

- International Organization for Standardization (ISO) – Standards for Chemical Testing and Quality Management. www.iso.org

- European Chemicals Agency (ECHA) – REACH Regulations on Silica. www.echa.europa.eu

- Kraus, G. "Reinforcement of Elastomers by Fillers." Rubber Chemistry and Technology, Vol. 51, No. 3, 1978.

- "Silica and Silicate Fillers." In: Wypych, G. (ed.) Handbook of Fillers, Second Edition. ChemTec Publishing, 2000.

- The Royal Society of Chemistry – Materials Science Journals and Databases. www.rsc.org