Introduction to Advanced Mica Flake Solutions

In demanding industrial sectors such as rubber, construction, and ceramics, material selection profoundly impacts product performance, durability, and cost-efficiency. High-performance functional fillers are essential to meet stringent application requirements. Among these, mica, known for its unique lamellar structure and exceptional properties, stands out.

Hezhen Shiye, a leader in advanced mineral solutions, provides premium-grade Hezhen Irregular Mica Flake for Rubber Construction Ceramics Industry. This specialized product is engineered to deliver superior reinforcement, insulation, and barrier properties, addressing critical challenges faced by manufacturers across these diverse industries. Our mica flakes are meticulously processed to ensure consistent quality and optimal performance, setting a new benchmark for industrial fillers.

The Manufacturing Process: From Ore to Advanced Flake

The production of high-quality Hezhen Irregular Mica Flake for Rubber Construction Ceramics Industry is a sophisticated process that begins with careful sourcing of raw materials and culminates in a finely engineered product. Our commitment to precision and quality control ensures that each batch meets the highest industry standards. The primary material is natural muscovite mica, renowned for its excellent mechanical and electrical properties.

Process Flow Overview:

- 1. Raw Material Sourcing & Inspection: We select high-purity muscovite mica ore from established quarries. Each batch undergoes rigorous incoming inspection for mineralogical composition, absence of contaminants, and initial quality assessment, adhering to internal Hezhen Shiye standards.

- 2. Primary Crushing: Large blocks of mica ore are fed into crushers, reducing them to smaller, manageable sizes. This stage utilizes advanced jaw and cone crushers to ensure efficient reduction while minimizing fines.

- 3. Grinding & Delamination: The crushed material is then transferred to specialized grinding mills (e.g., hammer mills or roller mills). Here, the mica is delaminated into thinner, irregular flakes, preserving its characteristic aspect ratio. This process is carefully controlled to achieve the desired particle size distribution.

- 4. Washing & Purification: The mica flakes undergo multiple washing cycles to remove impurities such as quartz, feldspar, and other mineral contaminants. This step is critical for achieving the high purity levels required for sensitive applications.

- 5. Drying: The washed mica flakes are dried in controlled environments to remove moisture content. Rotary dryers or fluid-bed dryers are employed to ensure uniform drying without affecting the flake integrity. Moisture content is critical for product stability and application performance.

- 6. Screening & Classification: Dried mica flakes are passed through a series of vibratory screens and air classifiers. This stage precisely separates the flakes into various size fractions, ensuring a consistent particle size distribution for specific customer requirements. Advanced sieving equipment is calibrated to meet industry-specific mesh sizes.

- 7. Quality Control & Packaging: Before packaging, each batch undergoes final quality checks, including particle size analysis (e.g., using laser diffraction), aspect ratio measurement, bulk density, and chemical composition analysis. Testing standards conform to international norms such as ASTM D6070 and relevant ISO guidelines. The finished Hezhen Irregular Mica Flake for Rubber Construction Ceramics Industry is then packaged in moisture-proof bags or jumbo bags, ready for dispatch.

Our manufacturing processes are meticulously designed to ensure the mica retains its superior physical and chemical properties, resulting in a product with an extended service life and exceptional performance in target industries. In rubber applications, our mica enhances tear strength and barrier properties; in construction, it improves fire resistance and dimensional stability; and in ceramics, it contributes to thermal shock resistance and green strength. These advantages translate directly into energy savings and enhanced corrosion resistance for end-products.

Industry Trends and Market Dynamics

The demand for advanced functional fillers is on a steady rise across key industrial sectors. Manufacturers are continuously seeking materials that can enhance product performance, improve sustainability, and reduce overall costs. The market for mica flakes is particularly influenced by several prevailing trends:

- Sustainability and Eco-Friendly Materials: Growing environmental consciousness drives demand for naturally occurring, non-toxic fillers like mica, which offer alternatives to synthetic or more energy-intensive materials.

- Performance Enhancement: Industries require materials that can deliver superior mechanical strength, thermal stability, electrical insulation, and barrier properties. Hezhen Irregular Mica Flake for Rubber Construction Ceramics Industry excels in these areas, offering solutions for higher-performance composites and coatings.

- Lightweighting: In automotive and construction, the drive for lighter materials without compromising strength or safety fuels the adoption of lightweight fillers and reinforcements. Mica's high aspect ratio and relatively low density contribute to this trend.

- Specialized Applications: Increasing complexity in product design and functionality necessitates highly specialized fillers. For example, in fire-retardant applications, mica's inherent non-combustibility and lamellar structure are invaluable.

- Urbanization and Infrastructure Development: Rapid urbanization, particularly in emerging economies, propels demand for construction materials that are durable, energy-efficient, and aesthetically pleasing, creating a strong market for mica in paints, coatings, and cementitious products.

These trends underscore the critical role of materials like our Hezhen Irregular Mica Flake for Rubber Construction Ceramics Industry in enabling the next generation of industrial products and processes.

Technical Specifications and Performance Parameters

The efficacy of Hezhen Irregular Mica Flake for Rubber Construction Ceramics Industry is defined by its precise technical specifications and inherent material properties. Our flakes are characterized by a high aspect ratio, excellent chemical inertness, superior thermal stability, and robust electrical insulating properties, making them ideal for high-performance applications. We provide a range of grades to suit varied industrial requirements.

Typical Product Specifications for Hezhen Irregular Mica Flake:

| Parameter | Typical Value (Example Grade: M-200) | Testing Standard |

|---|---|---|

| Particle Size (D50) | 50 - 75 µm | ISO 13320 / ASTM D4464 |

| Aspect Ratio (Avg.) | 30:1 - 80:1 | Internal Hezhen Method (Image Analysis) |

| Purity (Mica Content) | ≥ 95% | ASTM D7190 |

| Moisture Content | ≤ 0.5% | ASTM D280 |

| Specific Gravity | 2.8 - 2.9 g/cm³ | ASTM D153 |

| pH Value | 7.0 - 9.0 | ASTM E70 |

| Mohs Hardness | 2.5 - 3.0 | Standard Mohs Scale |

| Max. Operating Temperature | Up to 800°C (1472°F) | Theoretical / Application Based |

These parameters are critical for engineers and product developers to ensure compatibility and optimal performance in their formulations. Our stringent quality control measures, including ISO 9001 certification, guarantee consistent product quality batch after batch.

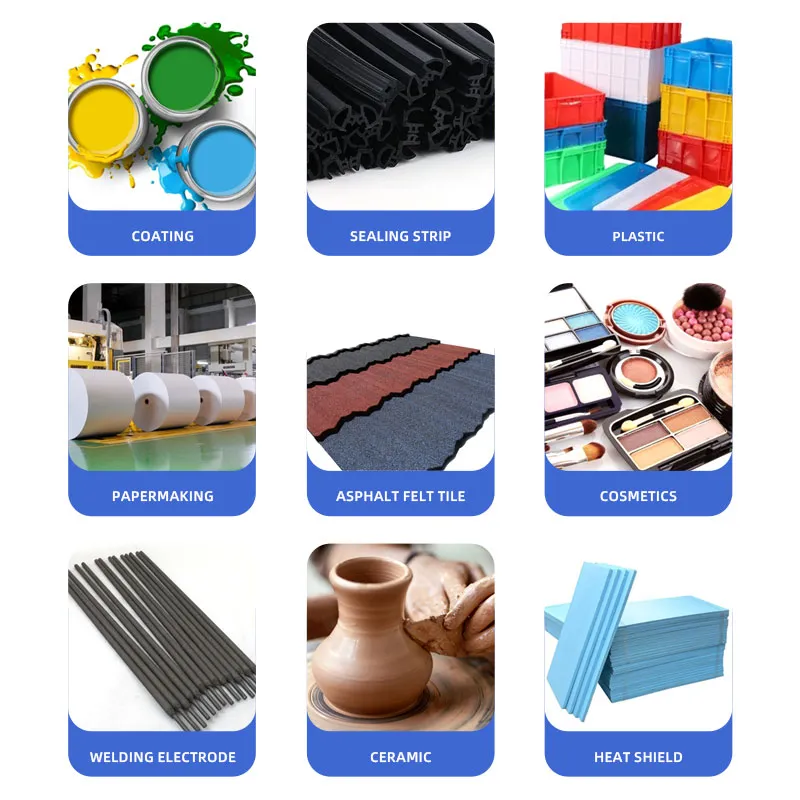

Application Scenarios Across Key Industries

The versatile properties of Hezhen Irregular Mica Flake for Rubber Construction Ceramics Industry make it an indispensable additive across a multitude of applications. Its lamellar structure imparts unique benefits that significantly enhance the performance and longevity of end products.

Rubber Industry:

- Reinforcement & Stiffness: In tires, belts, and hoses, mica flakes improve tensile strength, tear resistance, and modulus, contributing to longer service life and reduced material consumption.

- Barrier Properties: The plate-like structure creates an impermeable barrier, reducing gas and liquid permeability in rubber products like seals, gaskets, and inner tubes. This enhances chemical resistance and reduces aging.

- Anti-Blocking & Anti-Stick Agent: Used as a dusting agent or filler in rubber compounds to prevent adhesion during processing and storage.

- Vibration Dampening: Contributes to improved acoustic and vibration dampening in rubber mounts and automotive components.

Construction Industry:

- Paints & Coatings: Imparts sheen, acts as a barrier to moisture and UV radiation, improves scrub resistance, and enhances crack prevention in architectural and industrial coatings. Used in road marking paints for reflectivity and durability.

- Joint Compounds & Plasters: Improves workability, reduces shrinkage, prevents cracking, and provides structural integrity to gypsum products and cements.

- Roofing Materials: Used as a surfacing agent on asphalt shingles and roofing felts to prevent sticking, improve weatherability, and reflect heat.

- Fire Resistance: Mica's non-combustible nature makes it an excellent additive for fire-retardant building materials, enhancing safety standards.

Ceramics Industry:

- Thermal Shock Resistance: In refractory bricks and ceramics, mica reduces thermal expansion, improving resistance to rapid temperature changes.

- Insulation: Acts as an excellent electrical and thermal insulator in specialized ceramic components.

- Green Strength: Improves the handling strength of unfired ceramic bodies, reducing breakage during processing.

- Glaze & Enamel Additive: Used to create unique aesthetic effects and improve the durability of glazes and enamels.

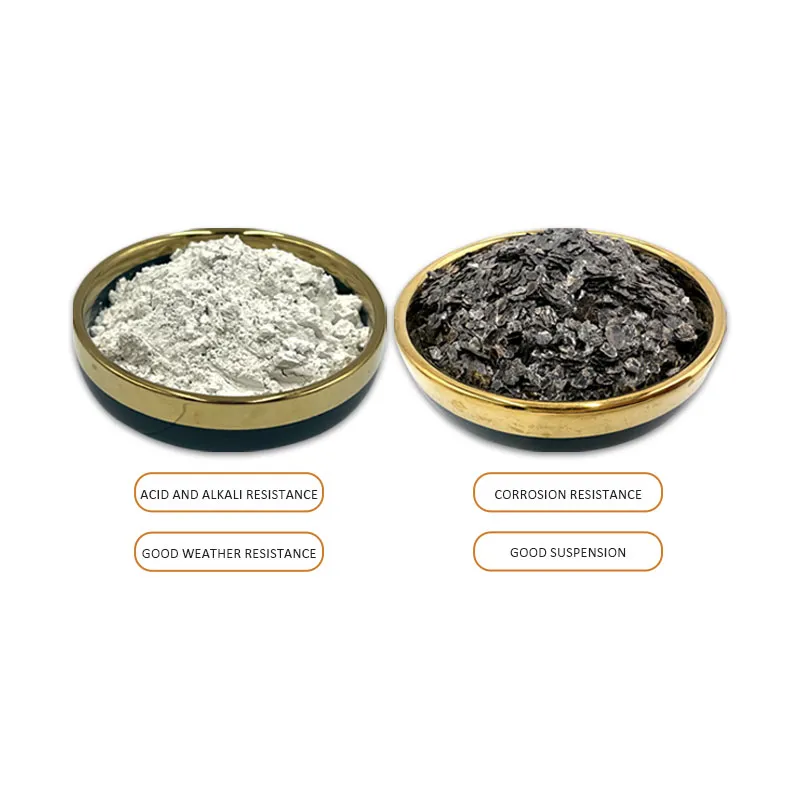

Technical Advantages of Hezhen Irregular Mica Flake

Hezhen Shiye's irregular mica flakes are not merely fillers; they are performance enhancers engineered to deliver significant technical and economic advantages. Our product differentiates itself through its consistent quality and optimized morphological characteristics.

- Exceptional Aspect Ratio: The irregular, plate-like structure provides a high aspect ratio (diameter-to-thickness ratio), which is crucial for effective reinforcement, barrier formation, and anti-sag properties in coatings. This leads to improved mechanical strength and reduced material usage.

- Superior Chemical Inertness: Mica is highly resistant to chemical attack, including acids, alkalis, and solvents. This makes our flakes ideal for corrosive environments and ensures long-term stability in various matrices.

- High Thermal Stability: With a decomposition temperature far exceeding typical application temperatures, Hezhen Irregular Mica Flake for Rubber Construction Ceramics Industry maintains its integrity and performance even under extreme heat, crucial for high-temperature composites and ceramics.

- Excellent Electrical Insulation: Naturally occurring mica is an outstanding electrical insulator. Our flakes provide high dielectric strength and low dielectric loss, making them valuable in electrical and electronic applications within ceramics and specialized rubbers.

- Enhanced UV Resistance: When incorporated into paints and plastics, mica provides an effective barrier against UV degradation, significantly extending the lifespan and aesthetic appeal of outdoor applications.

- Reduced Shrinkage and Cracking: In polymer and cementitious systems, mica's reinforcing effect and low coefficient of thermal expansion help minimize shrinkage, warping, and cracking, leading to more dimensionally stable products.

- Cost-Effectiveness: By enhancing durability, reducing maintenance, and sometimes allowing for a reduction in other, more expensive ingredients, Hezhen mica flakes offer significant long-term cost savings.

These advantages underscore why Hezhen's mica flakes are a preferred choice for engineers and manufacturers striving for peak product performance.

Vendor Comparison and Hezhen's Competitive Edge

Choosing the right supplier for industrial minerals is paramount. While many vendors offer mica, Hezhen Shiye distinguishes itself through a blend of product quality, technical expertise, and customer-centric services. Our commitment to continuous improvement and stringent quality assurance processes provides a distinct competitive advantage.

Comparative Analysis: Hezhen Shiye vs. Generic Suppliers

| Feature/Parameter | Hezhen Irregular Mica Flake | Generic Mica Flake Suppliers |

|---|---|---|

| Raw Material Purity | ≥ 95% Muscovite, meticulously selected. | Variable, often lower purity with more contaminants. |

| Particle Size Consistency | Tight distribution, precise classification (e.g., D50 ± 5µm). | Broader distribution, less consistent, impacts performance. |

| Aspect Ratio Optimization | Engineered for high aspect ratio (30:1 to 80:1) to maximize functional benefits. | Often lower aspect ratio, resulting in reduced reinforcement/barrier properties. |

| Quality Control & Certification | ISO 9001 certified, comprehensive in-house lab testing for every batch. | May lack formal certifications, inconsistent testing. |

| Technical Support & Customization | Dedicated technical team, custom solutions, formulation advice. | Limited or no technical support, standard products only. |

| Supply Chain Reliability | Robust logistics, consistent supply, global reach. | Potential for supply disruptions, inconsistent delivery. |

Hezhen Shiye’s focus on quality, precision, and customer value ensures that our Hezhen Irregular Mica Flake for Rubber Construction Ceramics Industry consistently outperforms, providing a reliable and superior input for your critical applications.

Customized Solutions and Collaborative Development

Recognizing that standard products may not always meet unique application demands, Hezhen Shiye offers extensive customization capabilities for our Hezhen Irregular Mica Flake for Rubber Construction Ceramics Industry. Our team of material scientists and engineers works closely with clients to develop tailor-made solutions.

- Particle Size Customization: We can adjust the D50 and particle size distribution to achieve specific flow properties, surface finishes, or reinforcement levels required for your unique production processes.

- Surface Treatment Options: For enhanced compatibility and dispersion in various polymer matrices, we offer surface-treated mica flakes, including silane or other coupling agents, optimizing adhesion and mechanical properties.

- Purity and Whiteness Grades: Depending on the application, we can provide ultra-high purity grades or specific whiteness levels to meet aesthetic or regulatory requirements.

- Specialized Packaging: From small industrial bags to large bulk container111s, our packaging solutions are adaptable to your operational needs, ensuring ease of handling and storage.

Our collaborative approach ensures that you receive a product perfectly optimized for your performance goals, leading to reduced development cycles and superior end-product quality. This flexibility positions Hezhen as a true partner in innovation.

Application Case Studies & Customer Success

Real-world application demonstrates the tangible benefits of incorporating Hezhen Irregular Mica Flake for Rubber Construction Ceramics Industry into diverse industrial products. Our customers consistently report significant improvements in performance and efficiency.

Case Study 1: Enhanced Automotive Rubber Seals

A leading automotive parts manufacturer sought to improve the durability and gas barrier properties of EPDM rubber seals used in engine compartments. They previously experienced premature aging and slight gas permeability issues. By integrating Hezhen's M-100 grade mica flake at a 15% loading, they observed a 25% improvement in tensile strength, a 40% reduction in gas permeability, and extended operational life in high-temperature environments. The lamellar structure of the mica created an effective tortuous path for gas molecules, significantly reducing permeation and enhancing the overall integrity of the seals. This resulted in fewer warranty claims and increased customer satisfaction.

Case Study 2: Durable Exterior Architectural Coatings

A large-scale construction paint producer aimed to develop a new line of exterior coatings with enhanced weather resistance and crack bridging capabilities. Traditional fillers provided insufficient performance. After trialing various solutions, they adopted Hezhen's M-200 grade mica flake. The irregular flakes contributed to a more robust paint film, improving elasticity by 18% and significantly reducing micro-cracking upon drying. The UV-blocking properties of the mica also extended the color retention and overall durability of the coating by an estimated 30% over a 5-year period. This allowed them to offer a longer warranty, a key competitive advantage.

Case Study 3: High-Performance Refractory Ceramics

An industrial ceramics manufacturer specializing in kiln furniture faced challenges with thermal shock failure in their high-alumina refractory products. Integrating a specific coarse grade of Hezhen Irregular Mica Flake for Rubber Construction Ceramics Industry (M-300) into their formulation led to a remarkable improvement. The mica's ability to introduce micro-cracks in a controlled manner, combined with its low thermal expansion, significantly improved the thermal shock resistance by 50%. This translated to fewer product failures, reduced replacement costs, and increased operational efficiency for their end-users in metallurgy and glass manufacturing.

Trust and Support: Your Partner in Success

At Hezhen Shiye, we understand that product quality goes hand-in-hand with reliable service and unwavering support. We are committed to fostering long-term partnerships built on trust and mutual success. Our operations are backed by robust certifications and transparent policies.

Frequently Asked Questions (FAQ):

Q1: What grades of Hezhen Irregular Mica Flake are available?

A1: We offer a comprehensive range of grades, typically from 20 mesh (coarse) down to 325 mesh (fine), with custom particle size distributions available upon request. Please consult our technical data sheets for specific grade details.

Q2: Is the mica chemically treated or natural?

A2: Our standard Hezhen Irregular Mica Flake for Rubber Construction Ceramics Industry is natural, untreated muscovite mica. However, we also offer surface-treated grades with silanes or other coupling agents to enhance compatibility with specific polymer systems.

Q3: What are your lead times for bulk orders?

A3: Standard lead times for bulk orders typically range from 2-4 weeks, depending on the specific grade and order volume. Expedited options may be available for urgent requirements. Please contact our sales team for precise lead time estimates.

Lead Time & Fulfillment:

Hezhen Shiye maintains robust inventory levels and efficient logistics to ensure timely delivery. Our typical lead time for standard products is 2-4 weeks from order confirmation, with flexibility for urgent requests or scheduled deliveries. We partner with reputable logistics providers to ensure secure and efficient global shipping, minimizing transit times and costs.

Warranty & Quality Assurance:

All Hezhen Irregular Mica Flake for Rubber Construction Ceramics Industry products are manufactured under strict ISO 9001:2015 certified quality management systems. We guarantee our products meet the specified technical parameters and are free from material defects. In the rare event of a quality discrepancy, our dedicated support team will work swiftly to resolve the issue in accordance with our comprehensive warranty policy, ensuring customer satisfaction.

Customer Support:

Our experienced technical and sales teams are available to provide expert advice, assist with product selection, and offer post-sales support. We provide detailed technical data sheets (TDS) and safety data sheets (SDS) for all products. For technical inquiries, custom solutions, or general support, please reach out via our website contact form, email, or telephone. We are committed to providing responsive and knowledgeable assistance.

Conclusion

The demand for advanced, high-performance materials in the rubber, construction, and ceramics industries continues to grow. Hezhen Shiye's Hezhen Irregular Mica Flake for Rubber Construction Ceramics Industry provides a proven solution, offering unparalleled benefits in reinforcement, insulation, and barrier properties. With stringent quality control, comprehensive technical support, and a commitment to customized solutions, Hezhen Shiye is your trusted partner for superior mineral additives. Explore how our mica flakes can elevate your products and processes.

References

- ASTM International. (2023). Annual Book of ASTM Standards. West Conshohocken, PA: ASTM International.

- ISO (International Organization for Standardization). (2023). ISO 9001:2015 Quality management systems – Requirements. Geneva, Switzerland: ISO.

- United States Geological Survey. (2023). Mineral Commodity Summaries 2023: Mica. Reston, VA: U.S. Geological Survey.

- European Mica Federation. (2022). Mica in Coatings and Polymers. Brussels, Belgium: European Mica Federation.

- The American Ceramic Society. (2023). Journal of the American Ceramic Society. Hoboken, NJ: Wiley-Blackwell.