Advancing Industrial Ceramics with High-Performance Calcined Kaolin

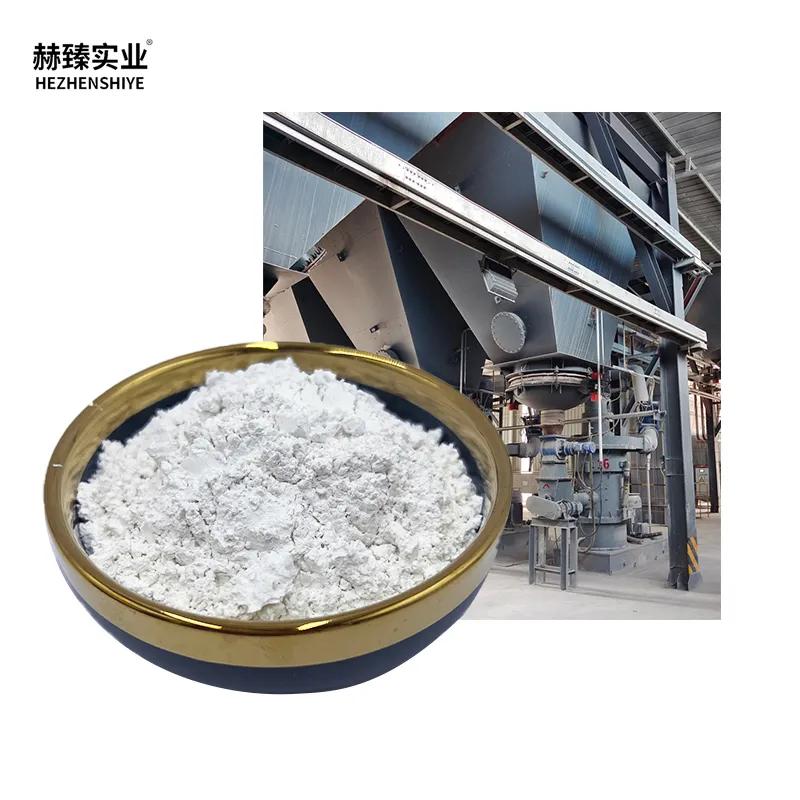

The modern industrial landscape demands materials that offer unparalleled performance, efficiency, and sustainability. In the realm of ceramic production, paper manufacturing, and specialized coatings, the quality of raw materials directly dictates the end product's integrity and market competitiveness. A pivotal innovation in this sector is Hezhen Ceramic glaze high adhesion rubber paper super white water wash calcined kaolin, a high-purity, extensively processed material engineered to meet the stringent demands of advanced applications. This specialized calcined kaolin is not merely an additive; it is a fundamental component designed to elevate product performance across a spectrum of industries.

Industry trends are increasingly focused on achieving superior whiteness, enhanced adhesion, and improved rheological properties in ceramic glazes, rubber compounds, and paper coatings. Manufacturers are pushing for materials that contribute to energy savings during processing, exhibit exceptional chemical stability, and maintain structural integrity under various operational conditions. The global market for calcined kaolin is experiencing steady growth, driven by expanding applications in high-performance ceramics, the rising demand for bright and durable paper products, and the continuous innovation in the paints and coatings sector. Environmental regulations are also influencing material selection, favoring products with low impurity levels and efficient processing characteristics. This evolution necessitates advanced materials like Hezhen's offering, which align with both performance and sustainability objectives.

The Advanced Manufacturing Process of Hezhen Calcined Kaolin

The superior characteristics of Hezhen Ceramic glaze high adhesion rubber paper super white water wash calcined kaolin are a direct result of a meticulously controlled, multi-stage manufacturing process designed to achieve optimal purity, whiteness, and functional properties. This process integrates advanced mineral processing techniques with rigorous quality assurance protocols, ensuring a product that consistently exceeds industry benchmarks.

Process Flow Overview:

- Raw Material Sourcing & Selection: High-grade kaolinite clay deposits are carefully selected for their low impurity levels and ideal mineralogical composition. This initial phase involves comprehensive geological surveys and detailed chemical analysis to ensure the raw material meets strict quality criteria. Key parameters like Al2O3 content and Fe2O3 levels are critical at this stage.

- Beneficiation (Washing & Flotation): The raw clay undergoes a multi-stage washing process to remove coarse impurities, sand, and other non-kaolinitic minerals. Advanced flotation techniques are then employed to separate fine particulate impurities, significantly enhancing the purity of the kaolin suspension. This step is crucial for achieving the "super white" characteristic.

- Slurry Preparation & Delamination: The purified kaolin is processed into a precisely controlled slurry. Mechanical and chemical delamination techniques are utilized to separate the kaolinite platelets, optimizing particle size distribution and increasing the surface area, which is vital for adhesion properties.

- Calcination: The delaminated kaolin slurry is dewatered and then subjected to high-temperature calcination in rotary kilns. This thermal treatment, typically between 800°C and 1100°C, removes structural hydroxyls (dehydroxylation), transforming the kaolinite into metakaolin and further into spinel and mullite phases at higher temperatures. This process dramatically improves whiteness, opacity, and chemical inertness. Precise temperature control is paramount to prevent sintering and maintain desired particle morphology.

- Water Wash & Milling: Post-calcination, the material undergoes a specialized water-wash treatment to remove any soluble salts or residual impurities that may have formed or become concentrated during calcination. This "water wash" step ensures ultra-high purity. Subsequently, the calcined kaolin is finely milled using advanced grinding equipment to achieve the target particle size distribution (e.g., D50 often below 2 microns) and shape, which are crucial for consistent rheology and excellent dispersion.

- Surface Treatment & Activation: Depending on specific application requirements, the finely milled calcined kaolin may undergo proprietary surface treatment processes. These treatments enhance dispersion in various media, improve hydrophobicity or hydrophilicity, and further boost adhesion characteristics, particularly relevant for rubber and paper applications.

- Quality Control & Packaging: Throughout the entire process, stringent quality control measures are implemented. Samples are regularly tested against international standards such as ISO 9001 and industry-specific benchmarks for whiteness (e.g., ISO Brightness), particle size, chemical composition, rheological properties, and adhesion performance. The final product is then carefully packaged to prevent contamination and ensure stability during transit and storage.

Target industries benefiting from this precise manufacturing process include petrochemical for catalyst supports, metallurgy for refractory components, and water supply & drainage for durable pipe coatings. The meticulously controlled calcination and washing steps ensure advantages such as superior corrosion resistance in aggressive chemical environments and significant energy savings due to optimized firing properties in ceramic applications, thereby extending the service life of end products.

Technical Specifications and Performance Parameters

The performance of Hezhen Ceramic glaze high adhesion rubber paper super white water wash calcined kaolin is defined by its precise technical specifications, which are critical for engineers and product developers seeking consistent and reliable material properties. These parameters ensure optimal integration and functionality across diverse applications.

Key Product Specifications:

| Property | Measurement Unit | Typical Value | Test Method/Standard |

|---|---|---|---|

| Whiteness (ISO Brightness R457) | % | ≥ 93 | ISO 2470 |

| Particle Size D50 | μm | 1.5 - 2.5 | Laser Diffraction (e.g., ISO 13320) |

| Top Cut (D90) | μm | ≤ 8 | Laser Diffraction |

| Oil Absorption | g/100g | 50 - 65 | ASTM D281 |

| Specific Surface Area (BET) | m²/g | 10 - 15 | ISO 9277 |

| Density | g/cm³ | 2.6 - 2.7 | ISO 787-10 |

| pH (10% slurry) | - | 6.0 - 7.5 | ISO 787-9 |

| Loss on Ignition (1000°C) | % | < 0.5 | ISO 787-2 |

| Refractive Index | - | 1.62 | ASTM D280 |

Chemical Composition (Typical, % by Weight):

- SiO₂: 52 - 54%

- Al₂O₃: 44 - 46%

- Fe₂O₃: < 0.1%

- TiO₂: < 0.15%

- K₂O + Na₂O: < 0.5%

These specifications underscore the high purity and consistent quality of Hezhen Ceramic glaze high adhesion rubber paper super white water wash calcined kaolin. The low levels of iron and titanium oxides contribute directly to its exceptional whiteness, while the controlled particle size distribution ensures superior rheological control and dispersibility in various matrices. The precise calcination process significantly reduces the Loss on Ignition (LOI), indicating thermal stability and minimal volatile content, which is critical for high-temperature applications like ceramic firing.

Technical Advantages and Diverse Application Scenarios

The distinctive properties of Hezhen Ceramic glaze high adhesion rubber paper super white water wash calcined kaolin translate into significant technical advantages across a multitude of industrial applications, driving enhanced performance and cost efficiencies for manufacturers.

Key Technical Advantages:

- Exceptional Whiteness and Opacity: The "super white" characteristic (ISO Brightness ≥ 93%) provides unparalleled brilliance in ceramic glazes, paints, and paper coatings. This high opacity also reduces the need for expensive TiO₂ pigments, offering significant cost savings while maintaining aesthetic appeal.

- Superior Adhesion and Mechanical Strength: The optimized particle size and surface chemistry contribute to excellent adhesion properties, particularly crucial for rubber compounds, where it acts as a reinforcing filler, and in paper coatings, enhancing printability and surface strength. In glazes, it improves adherence to the ceramic body, reducing defects.

- Enhanced Rheological Control: The controlled morphology and fine particle size ensure stable and predictable rheology in slurries and suspensions, vital for uniform application in glazes and coatings, and for maintaining processability in rubber and plastic compounding.

- High Chemical Inertness and Thermal Stability: As a calcined product, it exhibits superior chemical resistance to acids and alkalis, and excellent thermal stability, making it suitable for high-temperature processes and durable end products. This contributes to improved corrosion resistance and product longevity.

- Low Abrasivity: The carefully processed fine particles exhibit low abrasivity, minimizing wear on processing equipment, which leads to reduced maintenance costs and extended equipment service life.

Diverse Application Scenarios:

- Ceramic Glazes & Bodies: Provides high whiteness, improved firing characteristics, and enhanced scratch resistance. It acts as a flux extender and improves glaze opacity and gloss. The high adhesion helps prevent crawling and pinholing. It also contributes to energy saving by potentially lowering firing temperatures while maintaining desired hardness and durability.

- Rubber Compounds: Functions as a semi-reinforcing filler, imparting improved tensile strength, tear resistance, abrasion resistance, and hardness to natural and synthetic rubbers. Its high adhesion to polymer matrices is particularly beneficial in tire compounds, conveyor belts, and technical rubber goods.

- Paper & Board Coatings: Enhances brightness, opacity, smoothness, and print gloss of paper and board. Its fine particle size ensures excellent coating coverage and processability, leading to high-quality graphic papers, labels, and packaging materials.

- Paints & Coatings: Serves as an excellent extender and flatting agent, improving scrub resistance, weatherability, and hiding power in architectural, industrial, and specialty coatings. Its inertness prevents chemical reactions, ensuring long-term color stability and corrosion resistance for painted surfaces.

- Plastics: Used as a functional filler to improve mechanical properties, dimensional stability, and surface finish in various plastic formulations, including PVC, polyethylene, and polypropylene.

Vendor Comparison and Customized Solutions

In a competitive market, selecting the right calcined kaolin supplier is paramount. While many vendors offer calcined kaolin, the distinct processing and quality control applied to Hezhen Ceramic glaze high adhesion rubber paper super white water wash calcined kaolin set it apart, delivering a tangible performance advantage. Understanding these differences is crucial for optimizing product formulations and manufacturing processes.

Comparative Analysis: Hezhen vs. Standard Calcined Kaolin

| Feature/Property | Hezhen Ceramic Glaze Calcined Kaolin | Standard Calcined Kaolin (Generic) |

|---|---|---|

| Whiteness (ISO R457) | ≥ 93% (Super White) | Typically 88-91% |

| Iron Oxide (Fe₂O₃) Content | < 0.1% (Ultra-Low) | Typically 0.2-0.5% |

| Particle Size Control | Highly Controlled (D50 1.5-2.5 μm), narrow distribution | Variable, often wider distribution |

| Adhesion Properties | High Adhesion, surface-engineered | Moderate, primarily mechanical bonding |

| Water Wash Process | Yes, multi-stage post-calcination wash | Rarely, if ever, post-calcination wash |

| Rheology Control | Excellent and consistent | Good but often less consistent |

| Impact on End Product | Superior whiteness, enhanced mechanicals, reduced defects, longer service life | Acceptable performance, but limits on ultimate quality |

This comparison highlights Hezhen's commitment to delivering a premium product. The "water wash calcined" distinction specifically refers to a post-calcination treatment that removes residual soluble salts and further refines the surface, contributing to exceptional purity and whiteness that generic products cannot match. This additional step ensures a cleaner, more reactive surface, which directly translates to the 'high adhesion' characteristic.

Customized Solutions:

Hezhen understands that standard specifications may not always perfectly align with unique application requirements. Therefore, we offer flexible customization options for Hezhen Ceramic glaze high adhesion rubber paper super white water wash calcined kaolin to optimize its performance for specific industrial needs. Our technical team works closely with clients to understand their challenges and develop tailor-made solutions:

- Particle Size Engineering: Fine-tuning the particle size distribution (D50, D90) to optimize rheology for specific coating weights or improve gloss/opacity in glazes.

- Surface Treatment Modifications: Applying specialized surface coatings to enhance dispersibility in particular polymer systems, adjust hydrophilicity/hydrophobicity, or further boost interfacial adhesion in complex matrices.

- Rheological Adjustments: Modifying the material's surface charge and particle interactions to achieve desired viscosity and shear-thinning properties for advanced formulations.

- Purity and Trace Element Control: For highly sensitive applications (e.g., electronic ceramics or medical-grade polymers), we can implement additional purification steps to achieve even lower trace element concentrations.

- Packaging Solutions: Offering diverse packaging options from bulk bags to specialized container111s to meet logistical and handling requirements.

Our commitment to collaborative development ensures that clients receive a product precisely engineered for their success, translating into measurable improvements in production efficiency and final product quality.

Application Case Studies and Customer Experience

Real-world application demonstrates the tangible benefits of Hezhen Ceramic glaze high adhesion rubber paper super white water wash calcined kaolin. Our partnerships with leading manufacturers across various industries have yielded significant improvements in product quality, process efficiency, and cost-effectiveness.

Case Study 1: High-Gloss Ceramic Tile Production

Client: A prominent European ceramic tile manufacturer specializing in premium architectural surfaces.

Challenge: The client sought to achieve a brighter, more uniform white glaze on their porcelain tiles while reducing the consumption of expensive opacifiers like zirconium silicate. They also faced occasional issues with glaze crawling and inconsistent rheology during high-speed application.

Solution: Hezhen provided a tailored formulation incorporating their super white water wash calcined kaolin. The material's high ISO brightness and fine, controlled particle size were key. Our technical team collaborated on optimizing the glaze slurry's rheology.

Results:

- Achieved a 5% increase in glaze whiteness (ISO Brightness) while simultaneously reducing zirconium silicate usage by 10%.

- Significantly improved glaze adhesion, eliminating crawling defects and ensuring a smoother, more uniform finish.

- Enhanced rheological stability of the glaze slurry, leading to fewer application issues and a 7% reduction in rework.

- Overall cost savings on raw materials and reduced production waste.

Case Study 2: Performance Rubber Compounding for Industrial Belts

Client: A leading Asian manufacturer of industrial conveyor belts requiring enhanced abrasion resistance and tensile strength.

Challenge: The client needed to improve the mechanical properties of their rubber compounds, particularly tear and abrasion resistance, without negatively impacting processability or increasing material cost disproportionately. Traditional fillers offered limited reinforcement.

Solution: Hezhen's high adhesion rubber paper grade calcined kaolin was incorporated as a partial replacement for other fillers. Its fine particle size and activated surface provided superior interaction with the polymer matrix.

Results:

- Improved tensile strength by 12% and tear strength by 8% in the final rubber compound.

- Increased abrasion resistance by 15%, leading to a longer service life for conveyor belts in demanding environments.

- Maintained optimal rheology during mixing and extrusion, ensuring consistent product quality.

- Successfully met new industry standards for durability and performance.

Trustworthiness, Support, and Logistics

Hezhen is dedicated to not only providing high-quality Hezhen Ceramic glaze high adhesion rubber paper super white water wash calcined kaolin but also ensuring a robust support infrastructure that builds trust and fosters long-term partnerships. Our commitment extends from product quality to reliable logistics and comprehensive after-sales service.

Frequently Asked Questions (FAQ):

Q1: What is the primary advantage of "water wash calcined" kaolin?

A1: The post-calcination water wash removes residual soluble salts and further purifies the kaolin, resulting in exceptionally high whiteness, improved chemical inertness, and a cleaner surface for superior adhesion in formulations.

Q2: How does Hezhen's calcined kaolin contribute to energy savings in ceramic production?

A2: Its optimized particle morphology and purity can allow for lower firing temperatures in glazes and ceramic bodies while maintaining desired strength and aesthetic properties, thereby reducing energy consumption.

Q3: Can this product be used in food-contact applications?

A3: While highly pure, specific regulatory compliance for food-contact applications varies by region and specific use. We recommend consulting our technical team and reviewing relevant certifications (e.g., FDA 21 CFR 175.300 for coatings) for your exact application.

Q4: What are the typical lead times for bulk orders?

A4: Standard lead times range from 2-4 weeks, depending on order volume, specific customization requirements, and destination. We maintain strategic inventory levels to facilitate prompt delivery and can provide expedited options upon request.

Q5: How does Hezhen ensure consistent product quality?

A5: Our manufacturing facilities adhere to ISO 9001:2015 quality management standards. Every batch undergoes rigorous testing for whiteness, particle size, chemical composition, and application-specific performance parameters before shipment. Certificates of Analysis (CoA) are provided with each order.

Lead Time & Fulfillment:

Hezhen prioritizes efficient order fulfillment. Our streamlined logistics network, combined with robust production capabilities, ensures reliable supply. For standard specifications and quantities, lead times are typically 14-28 calendar days from order confirmation. For highly customized products or exceptionally large volumes, our sales team will provide a detailed and accurate lead time estimate. We work with trusted global shipping partners to ensure on-time and secure delivery to your facility, adhering to Incoterms 2020 standards as agreed upon.

Warranty & Quality Assurance:

Hezhen guarantees that our calcined kaolin products conform to the agreed-upon technical specifications as documented in our product data sheets and Certificates of Analysis (CoA). We provide a standard warranty period of 12 months from the date of shipment, covering material defects or non-conformance to specifications. In the unlikely event of a quality issue, our dedicated technical support team will promptly investigate and work towards a satisfactory resolution, including product replacement or credit, as per our terms and conditions.

Customer Support & Technical Assistance:

Our commitment to customer success extends beyond product delivery. Hezhen offers comprehensive technical support, including:

- Expert Consultation: Our team of material scientists and application engineers is available to provide guidance on product selection, formulation optimization, and troubleshooting.

- Technical Documentation: Access to detailed product data sheets, safety data sheets (SDS), and application guidelines.

- On-site Support: For complex projects or significant challenges, on-site technical visits can be arranged to provide direct assistance.

- Responsive Communication: Dedicated account managers ensure prompt and clear communication throughout your engagement with Hezhen.

Conclusion

The demand for advanced functional fillers and extenders in high-performance industrial applications continues to grow. Hezhen Ceramic glaze high adhesion rubber paper super white water wash calcined kaolin stands as a testament to innovation in mineral processing, offering an exceptional blend of purity, whiteness, adhesion, and rheological control. Its meticulously engineered properties provide significant advantages in ceramic glazes, rubber compounds, paper coatings, and various other specialty applications, enabling manufacturers to achieve superior product quality, enhance process efficiency, and meet evolving market demands for sustainable and high-performance materials. Partnering with Hezhen ensures access to not only a premium product but also comprehensive technical expertise and reliable customer support, driving sustained success for our clients.

References:

- Murray, H. H. (2007). Applied Clay Mineralogy: Occurrences, Processing, and Applications of Kaolins, Smectites, Palymgorskite, Sepiolite, and Zeolites. Elsevier.

- Brindley, G. W., & Brown, G. (1980). Crystal Structures of Clay Minerals and Their X-ray Identification. Mineralogical Society.

- Grim, R. E. (1962). Applied Clay Mineralogy. McGraw-Hill.

- ISO 9001:2015 - Quality management systems — Requirements. International Organization for Standardization.

- ASTM D281-95 (2002) - Standard Test Method for Oil Absorption of Pigments by Spatula Rub-Out. ASTM International.