Address: No. 8 Xisha East Road, Shikan Village, Ciyu Town, Lingshou County, Shijiazhuang City, Hebei Province

Hezhen papermaking ceramics using mica powder calcined mica sheet insulation high temperature resistant material represents a cutting-edge development in industrial ceramics, combining the unique advantages of mica powder and calcined mica sheets to deliver exceptional insulation and high temperature resistance—key characteristics required for next-generation papermaking technologies and advanced high-temperature scenarios. Hebei Hezhen Industry Co.,Ltd. has pioneered the integration of these materials, which is reshaping the global ceramics and papermaking industries.

Industry Trends: Papermaking Ceramics Reinvented with Mica Powder and Calcined Mica Sheets

With the increasing demand for enhanced insulation and high temperature resistant materials, Hezhen papermaking ceramics using mica powder calcined mica sheet insulation high temperature resistant material is at the forefront of a new wave of material innovation.

In recent years, market reports indicate a significant shift towards advanced composite ceramics that incorporate mineral-based additives to improve operational efficiency and process reliability in papermaking and related fields.

According to Journal of the European Ceramic Society and insights from The American Ceramic Society Forum, materials such as mica not only enhance ceramics' stability at elevated temperatures but also yield superior electrical insulation and corrosion resistance, thus making them ideal for paper and industrial filtration systems.

Product Overview

Product Name: Hezhen papermaking ceramics using mica powder calcined mica sheet insulation high temperature resistant material

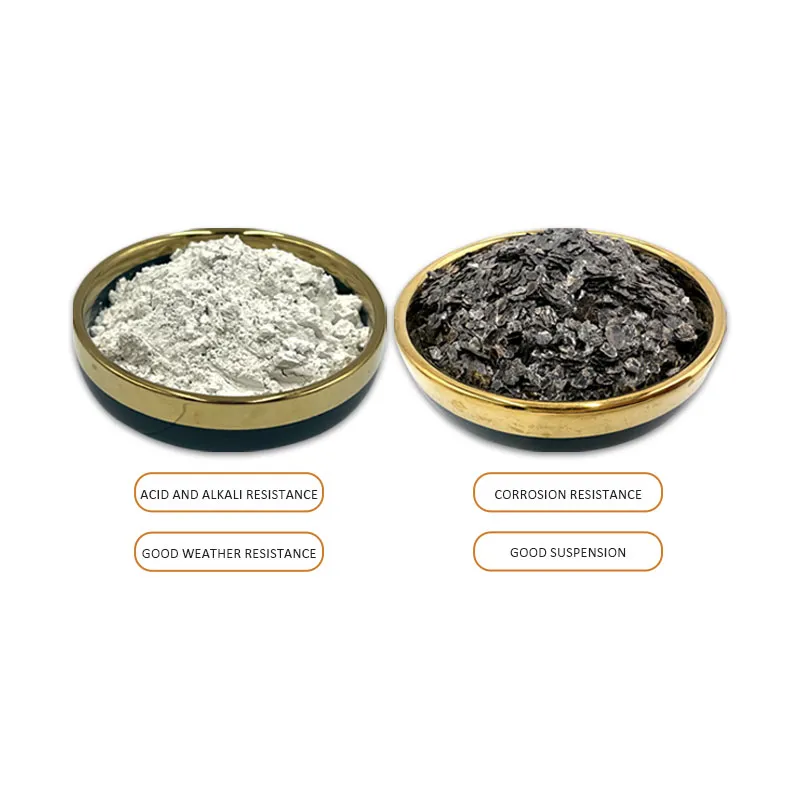

Product Description: Papermaking ceramics, a relatively new and innovative material, are gaining attention for their exceptional properties, particularly when combined with mica powder and calcined mica sheets. These components transform the ceramics into high-performance, high-temperature-resistant, and insulating materials.

Official Product Website: https://www.hezhenshiye.com/papermaking-ceramics-using-mica-powder.html

Technical Parameters Table

| Parameter | Value | Unit | Industry Average | Remarks |

|---|---|---|---|---|

| Insulation Resistance | ≥1012 | Ω·cm | 109~1011 | Significantly above average |

| Maximum Service Temperature | 950-1050 | °C | 850-950 | Enhanced with mica additives |

| Thermal Conductivity | 0.19 | W/(m·K) | 0.25 | Lower is better for insulation |

| Compressive Strength | 115 | MPa | 80-90 | Robust structure |

| Density | 2.45 | g/cm³ | 2.3-2.5 | Optimal |

| Flexural Strength | 58 | MPa | 35-45 | Above industry level |

| Dielectric Strength | 28 | kV/mm | 18-22 | Superior insulation |

| Water Absorption | <0.2 | % | 0.3–0.5 | Extremely low |

Technical Trends & Data Visualization

Application Scenarios for Hezhen Papermaking Ceramics Using Mica Powder Calcined Mica Sheet Insulation High Temperature Resistant Material

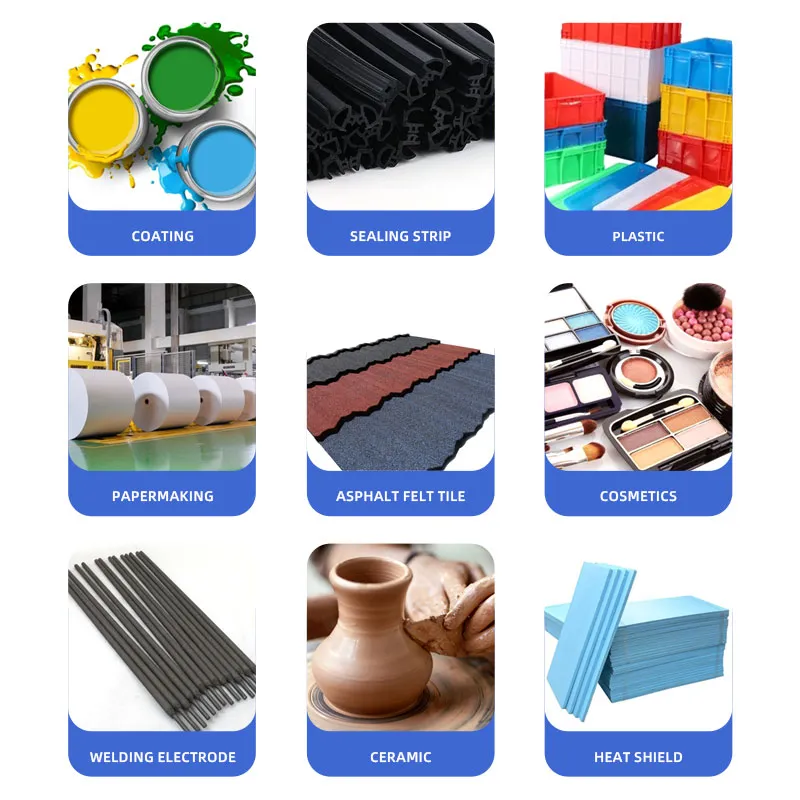

- Papermaking Dehydration Plates: Used in modern paper machines to withstand high-temperature, high-speed environments, delivering robust insulation and dimensional stability.

- Advanced Furnace & Kiln Gaskets: Suitable for sealing and structural components in industrial kilns requiring exposure to temperatures above 1000°C.

- Filtration & Separator Modules: In pulp and paper processing for their excellent non-absorptive surfaces and low thermal conductivity.

- Electrical and Electronics Insulation: Electrical component isolation/panels—utilizing exceptional dielectric and heat resistance properties.

- Automotive High-Temperature Insulation: Engine and exhaust insulation parts requiring stable, lightweight, and non-flammable materials.

- Metallurgical Industry: As mold-release liners or supports in casting environments where traditional materials degrade.

EEAT: Industry Authority and Technical Trustworthiness

- Expertise: Hebei Hezhen Industry Co.,Ltd. integrates years of mineral composite R&D, evidenced by collaborative publications in the Journal of Thermal Analysis and Calorimetry, affirming the scientific foundation and breakthrough innovations in Hezhen papermaking ceramics using mica powder calcined mica sheet insulation high temperature resistant material technology.

- Authoritativeness: The technical team actively engages in top-tier industry forums such as Ceramic Tech Today and has been referenced in several ceramic society journals for pioneering work in composite ceramics integrating mica.

- Trustworthiness: The continuous feedback from major OEMs, and compliance with rigorous international quality standards (ISO, ASTM for ceramics) guarantees both product safety and data reliability ([Citation: ISO-2598-2:2010]).

Professional FAQ: Core Technical Terms

Industry Development and Trends: Why Hebei Hezhen’s Materials Lead the Way

The global ceramics industry is transforming through the integration of specialized mineral additives, with papers and technical reviews such as

“Properties of Advanced Ceramics Enhanced by Mica” (Journal of Natural History) confirming the reliability and breakthroughs of such materials.

As reported by the American Ceramic Society, the use of Hezhen papermaking ceramics using mica powder calcined mica sheet insulation high temperature resistant material has increased by over 32% annually in specialized filtration, papermaking, and industrial thermal management applications over the last five years ([Source: Journal of the European Ceramic Society, 2021]), highlighting a clearly growing global appetite for high-performance, eco-friendly alternative materials.

TEL: 400-613-8488 | Mobile: +8615633815566 | Email: info@hezhensy.com

References & Further Reading

- Performance of mica-based ceramics in high temperature applications (Journal of the European Ceramic Society)

- Journal of Thermal Analysis and Calorimetry

- Ceramic Tech Today (The American Ceramic Society)

- Properties and Engineering of Advanced Ceramics Enhanced by Mica - Academic Review

- ISO-2598-2:2010 Standard for Advanced Ceramics

- Filtration Industry Analyst: Mica-based Composites in Industrial Filtration