Product Description

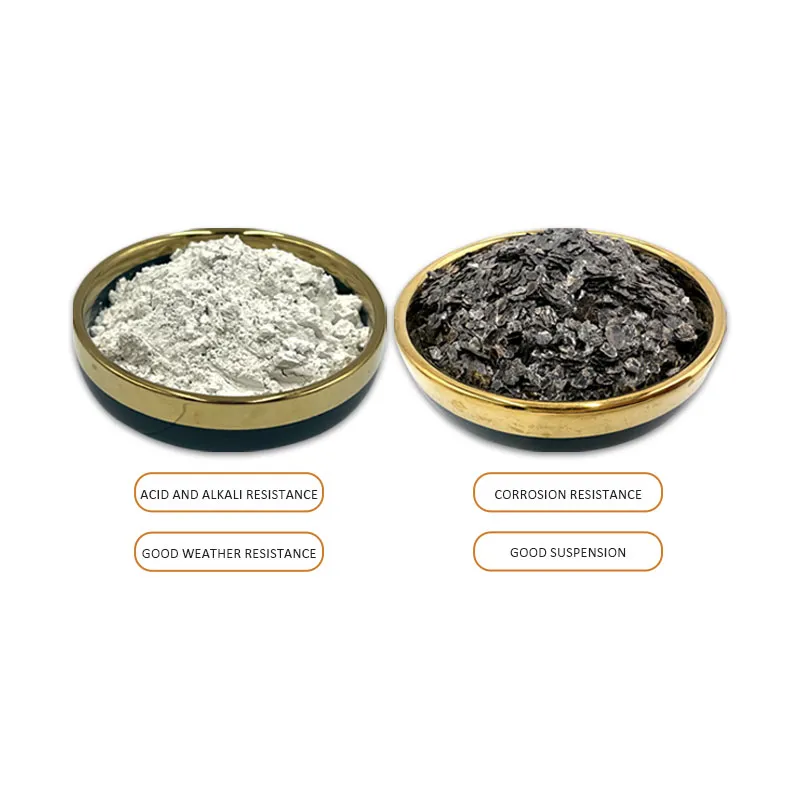

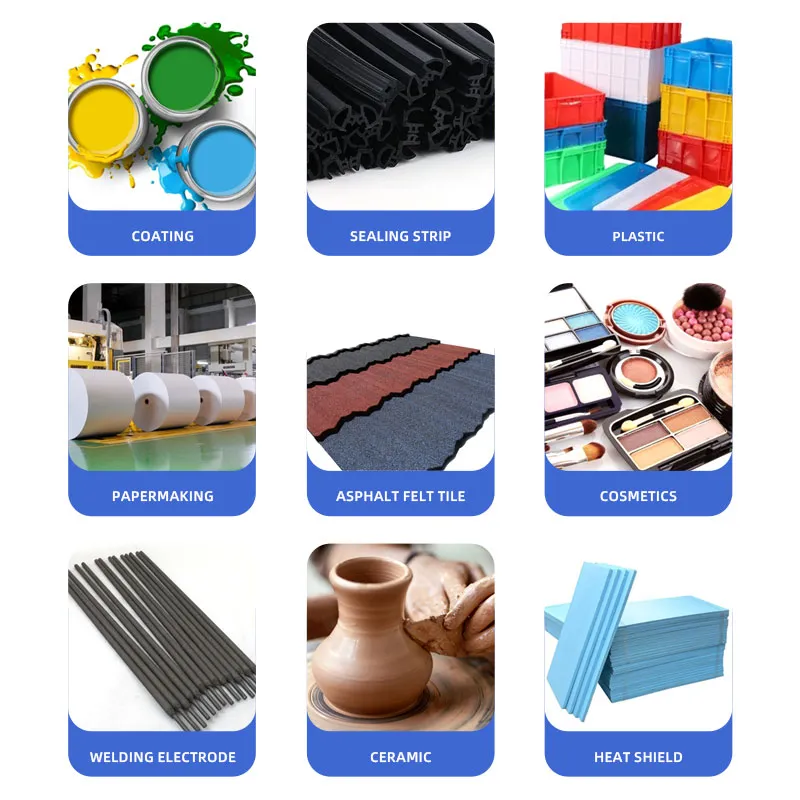

Mica powder, with its unique layered structure, is a key ingredient in papermaking ceramics. When added during the manufacturing process, it enhances the material's thermal stability. The fine particles of mica powder disperse evenly within the ceramic matrix, creating a barrier that effectively slows down heat transfer. This makes papermaking ceramics ideal for applications where insulation is crucial, such as in high - temperature industrial furnaces, electrical insulators, and aerospace components.

Calcined mica sheets further elevate the performance of papermaking ceramics. Calcination, a high - temperature treatment process, alters the structure of mica, increasing its strength and heat resistance. When integrated into the ceramics, these sheets provide additional reinforcement, preventing cracking and deformation at elevated temperatures.

The combination of mica powder and calcined mica sheets not only improves the insulation and high - temperature resistance of papermaking ceramics but also enhances their mechanical properties. As the demand for materials that can withstand extreme conditions grows, papermaking ceramics with mica - based additives are poised to play a significant role in various industries, offering a reliable and efficient solution for thermal management.

| Place of Origin | China |

| Color | White/Gold/Black/Silver |

| Shape | Flake/Powder |

| Purity | 90-95% |

| Grade | industrial Grade Food Grade |

| Package | 25kg/bag,customized package |

| MOQ | 1kg |

Banner PDF

Banner PDF Get A Quote

Get A Quote