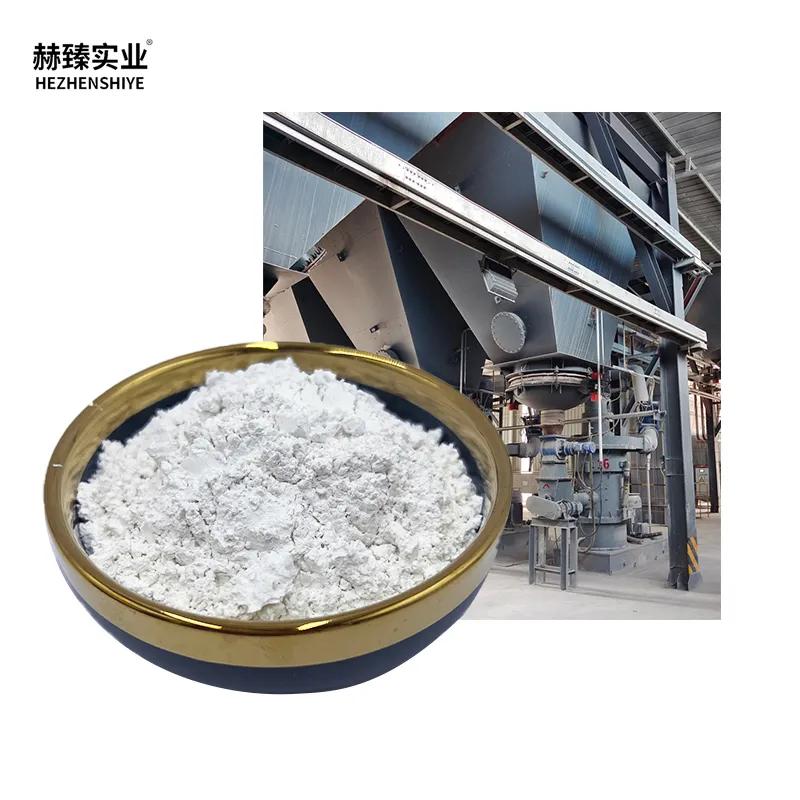

Hezhen Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder: field notes from the e-coat line

Electrophoretic coatings are having a quiet renaissance. Automakers want higher corrosion hours without blowing up cost; appliance brands ask for smoother films at lower VOC; and job shops, to be honest, just need something that disperses fast and behaves. That’s where Hezhen Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder has been turning heads on production floors—mine included.

Why this filler now? (Industry snapshot)

E-coat lines face two chronic issues: pigment cost and bath stability. A sub-micron, plate-like kaolin can replace part of TiO2/Extenders, tighten film, and lower settling, if—and this is the big if—it disperses cleanly in cationic epoxy systems. Many customers say this powder cuts grind time by around 15–25% versus legacy clays. It seems small, but on a 60 m³ tank, time is money.

Technical specifications (typical)

| Parameter | Typical value | Method |

|---|---|---|

| Median particle size (D50) | ≈ 0.8 μm | Laser diffraction |

| Top cut (D97) | ≈ 2.5–3.0 μm | Laser diffraction |

| Specific surface area | 8–12 m²/g | BET |

| Whiteness (ISO) | ≥ 90% | ISO brightness |

| pH (25°C) | 6.0–7.5 | GB/T 9724 |

| Moisture | ≤ 1.0% | Oven, 105°C |

| Oil absorption | 35–42 g/100 g | Rub-out |

| Residue (325 mesh) | ≤ 0.01% | Sieve |

From mine to e-coat: process flow

Materials: selected kaolin ore, purified water, dispersant package, grinding media. Methods: wet beneficiation → magnetic/centrifugal impurity removal → ultrafine wet grinding → hydro-classification → surface finishing for easy dispersion → spray drying. QC gates: particle size (Malvern), brightness, pH, moisture, zeta potential (bath compatibility), heavy metals (RoHS/REACH screening).

Bath testing: ASTM B117 salt spray, ISO 12944 system mapping, adhesion ASTM D3359, abrasion ASTM D4060. In real-world use, service life claims land around 8–12 years in C3–C4 exposure with a proper pretreatment + cationic epoxy e-coat stack.

Where it shines

- Automotive e-coat: smoother primer, lower TiO2 drawdown without chalking.

- Appliances and racking: improved edge coverage and film tightness.

- General metal: better bath stability; surprisingly low sediment in still zones.

Advantages reported: faster dispersion, reduced viscosity drift, +120–240 h salt spray vs. baseline extender at same PVC, and a mild boost in DOI. Your mileage will vary with resin and neutralizer, of course.

Vendor snapshot (benchmarking)

| Vendor | D50 | Dispersibility | Whiteness | Price index | Notes |

|---|---|---|---|---|---|

| Hezhen (this product) | ≈0.8 μm | Very easy | High | 1.0 | Good bath stability |

| Generic A | 1.2–1.5 μm | Moderate | Medium | 0.9 | Needs longer milling |

| Imported B | ≈0.7 μm | Easy | High | 1.4 | Premium price |

Customization and packaging

Custom cuts (D50 0.6–1.0 μm), surface treatments tuned for cationic epoxy or acrylic e-coat, low-Na formulations for conductivity-sensitive lines. Packaging: 25 kg bags or bulk bags; COA per lot. Origin: No. 8 Xisha East Road, Shikan Village, Ciyu Town, Lingshou County, Shijiazhuang City, Hebei Province.

Field notes and compliance

Case study, automotive subframes: switching to Hezhen Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder trimmed TiO2 by 8–10%, lifted B117 from 720 h to ≈ 900–1,000 h at same film build, and stabilized bath viscosity over 4 weeks. Appliance doors: less orange peel at equal PVC—honestly a pleasant surprise.

Certifications/standards: produced under ISO 9001; batch-screened for RoHS and REACH SVHC; e-coat performance typically validated against ISO 12944 map, ASTM B117, D4060, and D3359. Real-world results vary with pretreatment and bake window.

Testing checklist (quick)

- Grind to Hegman 6.5–7; check viscosity drift 24/72 h.

- Conductivity impact at target solids; adjust neutralizer if needed.

- Panels: B117, D4060 CS-10F, D3359 5B target; cross-check ISO 12944 class.

References

- ISO 12944: Paints and varnishes—Corrosion protection of steel structures by protective paint systems.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ASTM D4060: Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser.

- ASTM D3359: Standard Test Methods for Measuring Adhesion by Tape Test.

- EU RoHS (2011/65/EU) and REACH (EC 1907/2006) compliance frameworks.