Introduction to Advanced Bentonite Solutions

In diverse industrial landscapes, the demand for versatile and high-performance material solutions is ever-growing. Among these, bentonite stands out as a critical mineral, valued for its unique properties in thickening, binding, adsorption, and waterproofing. This comprehensive article delves into the multifaceted applications and technical superiority of Hezhen Waterproof material bentonite -thickener cat litter oilfield drilling foundry industry, exploring its manufacturing intricacies, performance benchmarks, and strategic advantages across key sectors. Our focus is on providing B2B decision-makers and technical engineers with profound insights into how this specialized bentonite can optimize operational efficiency and product quality.

Bentonite, primarily composed of montmorillonite, offers unparalleled thixotropic and swelling capabilities when hydrated, making it indispensable in environments requiring rheological control, sealing, or adsorption. From enhancing the integrity of drilling fluids to ensuring the cleanliness of pet environments and fortifying casting molds, the bespoke formulations developed by Hezhen address specific industrial challenges with precision and reliability.

Industry Trends and Market Dynamics

The global bentonite market is experiencing robust growth, driven by increasing demand from the oil & gas, construction, foundry, and pet care industries. Projections indicate a compound annual growth rate (CAGR) of approximately 4-6% over the next five years, with significant innovation focused on enhanced performance, environmental sustainability, and cost-effectiveness. Key trends include:

- Sustainable Solutions: A growing emphasis on environmentally friendly and naturally derived materials, positioning bentonite as a preferred choice over synthetic alternatives.

- Advanced Drilling Fluids: Increasing deep-water and unconventional oil & gas exploration drives demand for high-performance bentonite to manage complex downhole conditions (e.g., high-temperature, high-pressure environments).

- Specialized Foundry Binders: Foundries seek bentonite formulations that offer superior green strength, mold stability, and reduced defects, particularly in complex casting processes.

- Premium Cat Litter Products: Consumer preference for highly absorbent, odor-controlling, and dust-free cat litter fuels innovation in bentonite-based formulations.

- Waterproofing and Geotechnical Engineering: Bentonite's inherent impermeability makes it critical in liner systems for landfills, ponds, and groundwater protection.

These trends highlight the critical role of specialized bentonite products, such as Hezhen Waterproof material bentonite -thickener cat litter oilfield drilling foundry industry, in meeting evolving industry requirements and ensuring operational excellence.

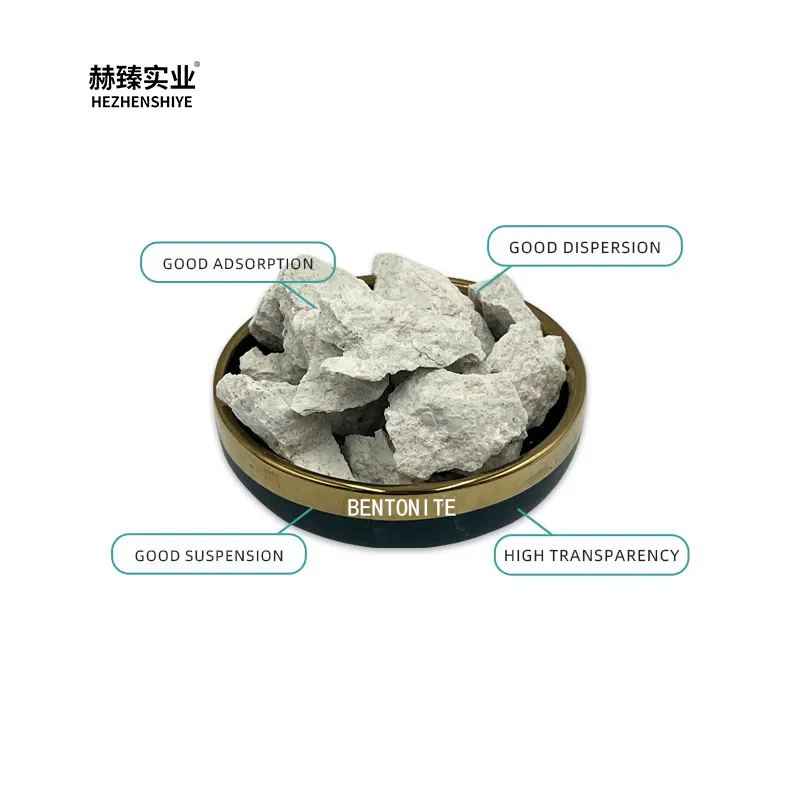

Figure 1: Bentonite in its natural processed state.

Process Flow: Manufacturing of Hezhen Bentonite

The production of Hezhen Waterproof material bentonite -thickener cat litter oilfield drilling foundry industry involves a meticulously controlled process to ensure consistent quality and optimized performance across its diverse applications. Our manufacturing methodology adheres to stringent international standards, including ISO 9001 for quality management and relevant ASTM/API specifications where applicable.

Manufacturing Process Steps:

- Raw Material Sourcing & Selection: High-grade sodium or calcium bentonite ore, primarily montmorillonite-rich, is ethically sourced from certified quarries. Strict quality checks are performed on raw ore for purity, swelling index, and cation exchange capacity (CEC).

- Crushing & Pre-Grinding: The raw ore undergoes primary crushing to reduce its size, followed by pre-grinding to prepare it for efficient drying and further processing.

- Drying: Moisture content is critical. The bentonite is dried in rotary kilns or flash dryers to precise specifications, typically below 10-12%, to prevent clumping and ensure optimal activation during hydration.

- Fine Grinding & Micronization: The dried material is then finely ground using roller mills or ball mills to achieve the desired particle size distribution, which directly impacts swelling, viscosity, and filtration properties. For specific applications like drilling muds, ultra-fine micronization may be employed.

- Activation (for Sodium Bentonite): Calcium bentonite often undergoes a sodium activation process, where sodium carbonate is added and thoroughly mixed to convert calcium ions to sodium ions, significantly enhancing its swelling and colloidal properties. This is a critical step for many waterproofing and drilling applications.

- Homogenization & Blending: The processed bentonite is homogenized to ensure uniform consistency. For customized solutions, specific additives (e.g., polymers, deflocculants, activators) are precisely blended to tailor the product's performance for particular applications (e.g., rheology control in drilling, enhanced clumping in cat litter, or superior green strength in foundry sands).

- Quality Control & Testing: Throughout the entire process, rigorous testing is conducted. This includes particle size analysis, moisture content, swelling index (e.g., API 13A Section 5.1), liquid limit (e.g., ASTM D4318), apparent viscosity, filtration loss (e.g., API RP 13B-1), and wet tensile strength for foundry applications.

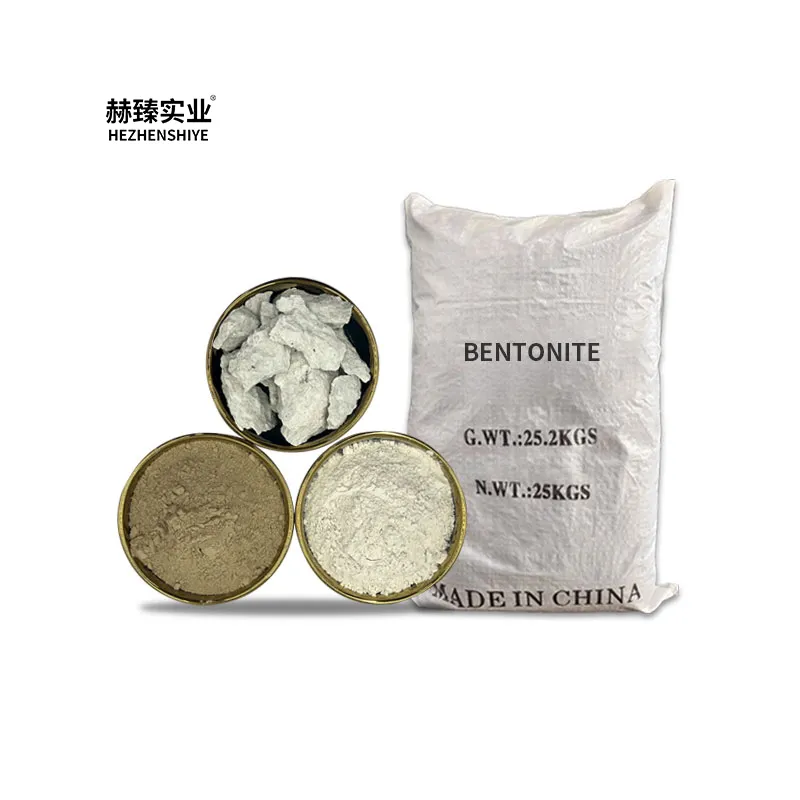

- Packaging & Distribution: The final product is packaged in various formats (e.g., 25kg bags, 1-ton jumbo bags) designed to protect material integrity and facilitate efficient handling and storage.

Figure 2: Quality control procedures for bentonite products.

Our dedication to these detailed process flows ensures a consistent, high-quality product with a service life optimized for demanding industrial environments, ultimately translating to energy saving and superior corrosion resistance in relevant applications. Target industries include petrochemical, metallurgy, water supply & drainage, and environmental engineering.

Technical Specifications and Performance Parameters

The efficacy of Hezhen Waterproof material bentonite -thickener cat litter oilfield drilling foundry industry is quantified by its adherence to rigorous technical specifications. Below is a representative table outlining typical performance parameters for our premium bentonite grades, which are engineered to exceed industry standards (e.g., API 13A for drilling-grade bentonite, ASTM E104 for moisture, AFS for foundry sand properties).

Hezhen Premium Bentonite Typical Specification

| Parameter | Unit | Typical Value Range | Relevant Standard |

|---|---|---|---|

| Montmorillonite Content | % | ≥ 85 | X-ray Diffraction |

| Swelling Index (2g in 100ml water) | ml | ≥ 18-24 | API 13A Section 5.1 |

| Liquid Limit | % | ≥ 400 | ASTM D4318 |

| Moisture Content | % | ≤ 10 | ASTM E104 |

| Sieve Residue (+200 mesh) | % | ≤ 2.5 | API 13A Section 5.2 |

| API Fluid Loss (max) | ml | ≤ 13.5 (for drilling grade) | API RP 13B-1 |

| Yield Point (600 rpm / 300 rpm) | Pa / cP | Varies by application | API RP 13B-1 |

These parameters ensure that our bentonite products deliver exceptional performance in their intended applications, providing optimal rheological control for drilling fluids, robust binding for foundry sands, superior absorbency for cat litter, and impermeable barriers for waterproofing.

Figure 3: Advanced laboratory testing for bentonite properties.

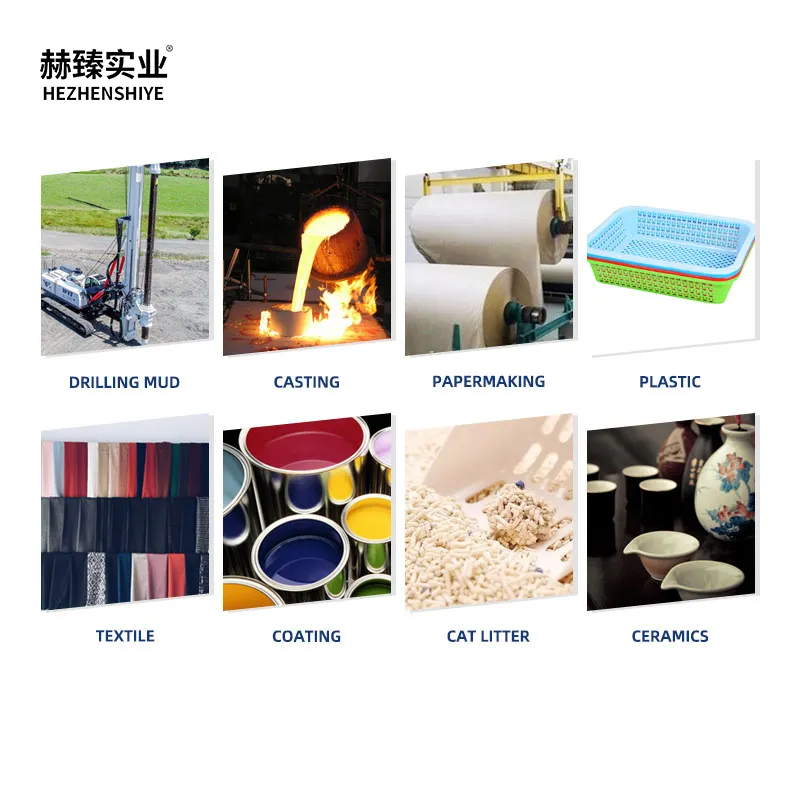

Diverse Application Scenarios

The remarkable versatility of bentonite allows for its application across a multitude of industries. Hezhen Waterproof material bentonite -thickener cat litter oilfield drilling foundry industry is specifically engineered to excel in several demanding sectors:

- Oilfield Drilling: As a primary component of drilling muds, bentonite provides viscosity, suspension of cuttings, and filter cake formation, preventing fluid loss and borehole instability. Its thixotropic properties are crucial for maintaining suspension when circulation stops and reducing pressure when pumping resumes.

- Foundry Industry: Bentonite serves as a vital binder in green sand molding, imparting plasticity, green strength, and thermal stability to molds. This ensures precise casting dimensions, smooth surface finishes, and reduced defects in ferrous and non-ferrous casting processes.

- Waterproofing & Geotechnical Engineering: The exceptional swelling capacity of sodium bentonite makes it an ideal impermeable barrier. It is used in bentonite geo-composite liners (GCLs) for landfills, pond liners, cutoff walls, and foundation sealing, providing effective containment and groundwater protection.

- Cat Litter Production: Highly absorbent bentonite is the backbone of clumping cat litter. Its ability to rapidly absorb liquids and form firm, easily scoopable clumps ensures superior odor control and cleanliness for pet owners.

- Thickener & Binder in Various Industries: Beyond these core applications, bentonite acts as a rheological modifier, thickener, and binder in diverse products, including paints, ceramics, agricultural feed pellets, and pharmaceutical formulations.

Figure 4: Bentonite applications in environmental sealing.

Technical Advantages of Hezhen Bentonite

Hezhen's commitment to quality and innovation translates into distinct technical advantages for our bentonite products, empowering clients with superior performance and reliability.

- Optimized Rheology & Thixotropy: Our bentonite offers exceptional viscosity and gel strength development, critical for suspending solids in drilling fluids and providing stability in thickening applications. This leads to reduced fluid loss and improved borehole stability in drilling.

- High Swelling Capacity: Particularly for waterproofing applications, the high swelling index of our sodium-activated bentonite creates robust, low-permeability barriers capable of self-sealing minor punctures or cracks, offering long-term protection.

- Superior Binding Strength: In the foundry industry, Hezhen bentonite provides excellent green strength and dry strength to molding sands, minimizing mold erosion and ensuring high-quality casting finishes with fewer defects.

- Efficient Adsorption & Odor Control: For cat litter, the microporous structure and high surface area of our bentonite enable rapid liquid absorption and effective encapsulation of odors, enhancing product performance and consumer satisfaction.

- Chemical & Thermal Stability: Engineered to withstand challenging industrial environments, our bentonite maintains its structural integrity and performance across a wide range of pH and temperature conditions, crucial in oilfield and metallurgical applications.

- Consistent Quality & Purity: Rigorous quality control measures ensure that every batch of Hezhen Waterproof material bentonite -thickener cat litter oilfield drilling foundry industry meets specified parameters for purity, particle size, and performance characteristics, leading to predictable results and operational consistency for our clients.

Figure 5: High-performance bentonite in industrial packaging.

Vendor Comparison: Why Choose Hezhen

Choosing the right bentonite supplier is paramount for ensuring consistent product quality and operational efficiency. While numerous vendors offer bentonite, Hezhen distinguishes itself through a combination of superior product quality, technical expertise, and client-centric service.

Hezhen vs. Generic Bentonite Suppliers

| Feature | Hezhen Waterproof material bentonite -thickener cat litter oilfield drilling foundry industry | Generic Bentonite Suppliers |

|---|---|---|

| Montmorillonite Purity | High (≥85%), consistent batches | Varies, often lower purity and inconsistent |

| Customization Capabilities | Extensive, tailor-made formulations for specific applications | Limited standard products, little to no customization |

| Technical Support | Dedicated technical team, application engineers, R&D support | Basic product information, minimal application guidance |

| Quality Certifications | ISO 9001, API 13A compliant grades, internal rigorous QMS | May have basic certifications, inconsistent adherence |

| Performance Consistency | Guaranteed batch-to-batch consistency due to advanced processing | Significant variability, leading to unpredictable results |

| Logistics & Reliability | Robust supply chain, on-time delivery, global reach | Potential for delays, limited geographic coverage |

Hezhen prides itself on not just supplying a product but providing a complete solution, backed by decades of experience and a client-first approach. Our product ensures enhanced operational performance and cost-effectiveness for our clients.

Figure 6: Global distribution and logistics network.

Customized Solutions and Application Case Studies

Recognizing that every industrial application has unique requirements, Hezhen offers highly customized bentonite solutions. Our expert R&D team collaborates closely with clients to develop formulations that precisely meet specific technical challenges, ensuring optimal performance and efficiency.

Customization Capabilities:

- Particle Size Distribution: Tailoring particle size for specific rheological profiles in drilling or optimal binding in foundry sands.

- Swelling Index & Viscosity: Adjusting activation levels and additives to achieve desired swelling capacity for waterproofing or viscosity for thickening.

- Additive Integration: Incorporating specific polymers, dispersants, or other functional additives to enhance performance characteristics like filtration control, thermal stability, or clumping strength.

- Chemical Modification: Developing specialized bentonite types for resistance to salt contamination, high temperatures, or extreme pH environments.

Application Case Studies:

Our Hezhen Waterproof material bentonite -thickener cat litter oilfield drilling foundry industry has been instrumental in numerous successful projects globally.

Case Study 1: Enhanced Drilling Fluid Performance in Deep-Sea Exploration

A major offshore drilling company faced challenges with fluid loss and borehole instability in deep-water wells characterized by high temperatures and pressures. Hezhen provided a customized bentonite formulation with enhanced filtration control and thermal stability. The client reported a 15% reduction in fluid loss and significant improvement in wellbore integrity, leading to a 7% reduction in non-productive time (NPT) and substantial cost savings.

Case Study 2: Superior Casting Quality in Automotive Foundry

An automotive component manufacturer struggled with surface defects and mold erosion in their casting operations. After implementing Hezhen's foundry-grade bentonite, tailored for optimal green strength and refractoriness, they observed a 20% reduction in casting defects. This resulted in higher production yields and reduced post-casting finishing, improving overall efficiency and product quality. Customer feedback highlighted the consistent batch quality and the responsive technical support from Hezhen.

Case Study 3: Large-Scale Landfill Liner Project

For a municipal solid waste landfill expansion, a geotechnical engineering firm required an impermeable barrier system. Hezhen supplied high-swelling, sodium-activated bentonite specifically designed for Geocomposite Clay Liners (GCLs). The project successfully achieved a permeability coefficient of 1x10-9 cm/s, exceeding regulatory requirements and providing a reliable, long-term containment solution. The ease of deployment and material consistency were praised by the engineering team.

Figure 7: Successful application of bentonite in a construction project.

Trust and Support: FAQ, Logistics, Warranty

Frequently Asked Questions (FAQ):

-

Q: What is the primary difference between sodium and calcium bentonite?

A: Sodium bentonite exhibits superior swelling properties when hydrated, making it ideal for waterproofing and drilling fluid applications requiring high viscosity and low permeability. Calcium bentonite has lower swelling capacity but is excellent for adsorption and often used in industrial absorbents or certain catalytic applications. Hezhen offers activated sodium bentonite variants with enhanced performance characteristics. -

Q: How does Hezhen ensure product quality and consistency?

A: We adhere to ISO 9001 quality management systems and conduct multi-stage testing, from raw material inspection to final product analysis, using international standards like API 13A and ASTM methods. Our advanced processing techniques and automated blending systems minimize batch-to-batch variation. -

Q: Can Hezhen bentonite be used in high-temperature drilling environments?

A: Yes, our specialized drilling-grade bentonite formulations are designed with enhanced thermal stability, suitable for high-temperature, high-pressure (HTHP) drilling conditions, maintaining rheological properties under challenging downhole environments. -

Q: What packaging options are available?

A: We offer flexible packaging solutions including 25kg paper bags, 1-ton jumbo bags, and bulk tanker deliveries, tailored to client requirements and logistics efficiency.

Lead Time & Fulfillment:

Hezhen maintains a robust supply chain and optimized production schedule to ensure timely delivery. Standard lead times for regular orders typically range from 7 to 14 business days, depending on order volume and destination. For customized formulations or large-scale projects, specific lead times will be communicated upon order confirmation. We work closely with our logistics partners to facilitate efficient global and domestic shipping.

Warranty & Customer Support:

Hezhen guarantees that all Hezhen Waterproof material bentonite -thickener cat litter oilfield drilling foundry industry products conform to the specifications outlined in our technical data sheets and agreed-upon client specifications. We warrant our products against defects in material and workmanship under normal use and storage conditions. Our dedicated customer support team and technical specialists are available to provide comprehensive pre-sales consultation, application guidance, and post-sales support to ensure optimal product performance and client satisfaction. For detailed warranty terms or technical inquiries, please contact our support team directly.

Conclusion

The advanced properties and diverse applications of Hezhen Waterproof material bentonite -thickener cat litter oilfield drilling foundry industry position it as a critical component in achieving operational excellence across the oilfield, foundry, waterproofing, and pet care sectors. Hezhen's commitment to precision manufacturing, rigorous quality control, and client-focused customization ensures that our bentonite solutions not only meet but exceed the demanding requirements of modern industry. Partner with Hezhen to leverage superior bentonite technology for enhanced performance, efficiency, and sustainability.

Authoritative References:

- American Petroleum Institute (API) Recommended Practice 13B-1: Standard Procedure for Field Testing Water-based Drilling Fluids.

- ASTM International Standards for Soil and Rock (e.g., D4318 for Liquid Limit, D5890 for Swell Index).

- International Organization for Standardization (ISO) 9001: Quality Management Systems – Requirements.

- American Foundry Society (AFS) standards for molding sand testing.

- Grim, R.E. (1962). Applied Clay Mineralogy. McGraw-Hill.