Introduction to Advanced Feed Additive Technology

In the dynamic landscape of animal nutrition, the demand for sophisticated feed additives that optimize animal health, enhance productivity, and ensure feed stability is ever-growing. Modern livestock and aquaculture operations require solutions that go beyond basic nutrient supplementation, addressing challenges such as mycotoxin contamination, digestive efficiency, and feed processing stability. This necessitates innovative material science and advanced manufacturing techniques to develop next-generation feed ingredients.

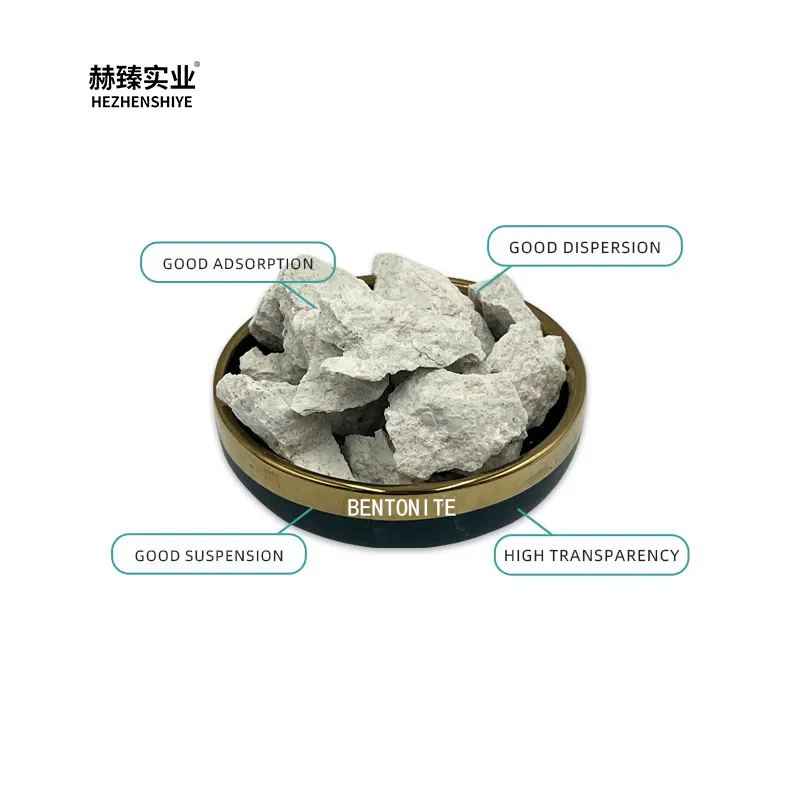

One such innovation is Hezhen Sodium-bentonite cast coating feed additive pulping does not precipitate hygroscopic expansion. This highly specialized product represents a significant leap forward in the application of bentonite in animal feed. Unlike conventional bentonites, the Hezhen variant is engineered with unique properties that prevent precipitation during liquid feed applications (pulping) while leveraging its natural hygroscopic expansion for optimal performance. Its cast coating technology ensures superior dispersion, controlled functionality, and consistent efficacy, making it an indispensable tool for feed manufacturers and livestock producers aiming for peak performance and safety.

Industry Trends in Advanced Feed Additives

The global animal feed industry is witnessing several transformative trends. Firstly, there's an increasing emphasis on sustainable and natural ingredients. Consumers and regulators are pushing for feed solutions that minimize environmental impact and reduce reliance on synthetic compounds. Sodium bentonite, being a natural clay mineral, aligns perfectly with this trend, provided it is processed to high purity standards.

Secondly, precision nutrition and functional feed additives are gaining traction. This involves tailoring feed formulations to specific animal life stages, genetic potentials, and environmental conditions to maximize feed conversion ratio (FCR) and overall health. Additives like Hezhen Sodium-bentonite cast coating feed additive pulping does not precipitate hygroscopic expansion, with its targeted properties, contributes significantly to this area by enhancing nutrient absorption and gut health.

Thirdly, feed safety and mycotoxin management remain paramount. Mycotoxins pose a severe threat to animal health and productivity. Advanced adsorbent technologies, leveraging the expansive surface area and cation exchange capacity (CEC) of bentonite, are crucial for effective toxin binding. The non-precipitating nature of Hezhen's product ensures consistent distribution and efficacy in liquid feed systems, where uniform dispersion is critical for optimal toxin adsorption.

Finally, the shift towards liquid feed applications and automated feeding systems demands additives that offer superior suspension stability and flow characteristics. Conventional bentonites can present challenges with sedimentation and clogging in liquid delivery systems. The innovative cast coating technology of the Hezhen product directly addresses these issues, ensuring seamless integration into modern, automated feed operations.

Technical Specifications and Parameters

The efficacy of Hezhen Sodium-bentonite cast coating feed additive pulping does not precipitate hygroscopic expansion is underpinned by its meticulously controlled technical specifications. These parameters ensure consistent quality, optimal performance, and compliance with stringent feed safety regulations.

Product Specification Table: Hezhen Sodium-Bentonite Feed Additive

The "Pulping Precipitation" parameter is particularly critical. This characteristic is achieved through a proprietary cast coating process that modifies the surface chemistry of the bentonite particles, preventing agglomeration and sedimentation when mixed into liquid solutions. This ensures uniform distribution of the active material throughout liquid feeds, delivering consistent benefits to the animals.

Detailed Manufacturing Process Flow

The production of Hezhen Sodium-bentonite cast coating feed additive pulping does not precipitate hygroscopic expansion involves a sophisticated multi-stage process, meticulously designed to achieve its unique properties. This process ensures the product's high purity, consistent particle morphology, and superior functional performance. The entire manufacturing chain adheres to stringent quality control protocols, including ISO 22000 and HACCP principles, to guarantee feed safety and efficacy.

Process Flow Overview:

- Raw Material Sourcing & Pre-Beneficiation: High-grade sodium bentonite ore is carefully selected from certified deposits. Initial crushing and coarse screening remove large impurities and rocks.

- Wet Beneficiation & Purification: The ore undergoes a wet beneficiation process, including hydraulic classification and hydrocyclone separation, to remove non-clay minerals (e.g., quartz, feldspar). This stage significantly enhances the montmorillonite content and overall purity.

- Slurry Preparation & Dispersion: The purified bentonite is then dispersed in water to form a precisely controlled slurry. Advanced high-shear mixers are employed to ensure complete delamination of montmorillonite layers and optimal particle dispersion.

- Proprietary Cast Coating Application: This is the core innovative step. A specialized organic or inorganic coating agent is introduced into the slurry under controlled conditions (temperature, pH, mixing speed). The "cast coating" process forms a uniform, ultra-thin protective layer around each bentonite particle. This coating is crucial for preventing particle aggregation and sedimentation during subsequent "pulping" (mixing with liquids), thereby ensuring the "does not precipitate" characteristic.

- Spray Drying & Granulation: The coated bentonite slurry is then fed into a spray dryer. This process rapidly removes moisture while forming spherical micro-granules or powder, depending on the desired final product form. The rapid drying helps to lock in the integrity of the cast coating.

- Sizing & Classification: The dried product undergoes precise sizing through sieving or air classification to achieve a narrow particle size distribution, optimizing its flowability and dispersion characteristics.

- Quality Control & Testing: Throughout the entire process, multiple checkpoints are implemented. This includes raw material analysis, in-process slurry viscosity, pH, particle size, coating efficacy, moisture content, CEC, swelling index, and rigorous heavy metal/mycotoxin screening in the final product. Final product batches are tested to confirm the "pulping does not precipitate" characteristic using standard lab protocols.

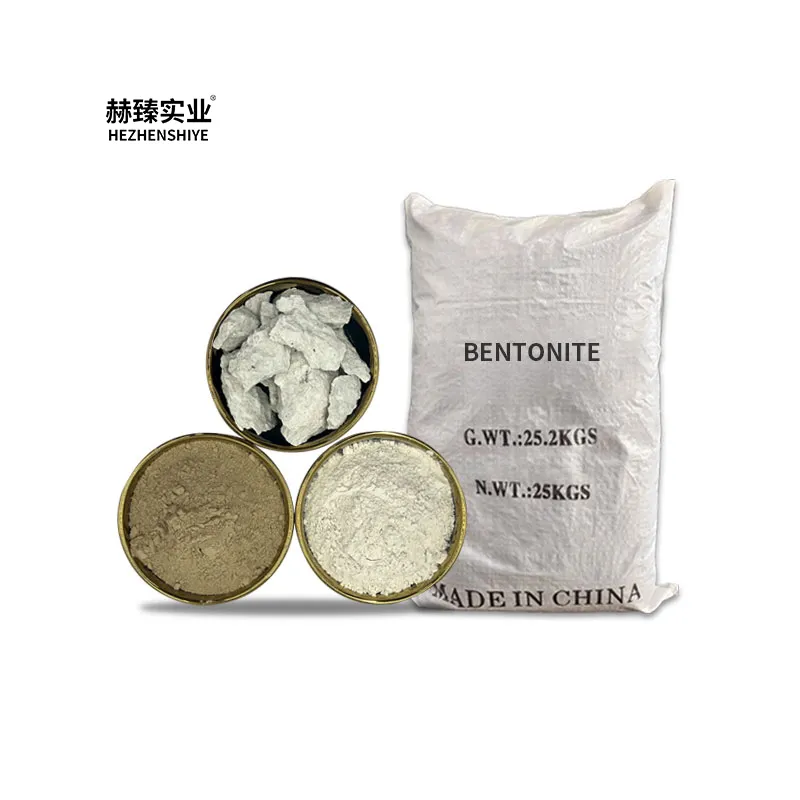

- Packaging: The finished product is packed in multi-ply paper bags with an inner liner or bulk bags, ensuring protection from moisture and contamination, and maintaining product integrity during storage and transport.

Key Advantages in Typical Application Scenarios (Feed Production):

- Energy Saving: The uniform particle size and non-precipitating nature reduce wear and tear on mixing equipment in feed mills, leading to lower energy consumption and maintenance costs. The controlled hygroscopic expansion also aids in better pellet quality, reducing energy required for pelletizing.

- Enhanced Mixing Efficiency: For liquid feed applications, the non-precipitating characteristic ensures homogeneity, reducing the need for continuous agitation and preventing "hot spots" or "cold spots" of additive concentration.

- Corrosion Resistance (Indirect): While not directly "corrosion resistance" in the traditional sense, the stable nature of the coated bentonite prevents the aggregation of raw bentonite particles that could lead to abrasive wear on pumps and piping in liquid handling systems, thereby indirectly extending equipment life.

- Extended Service Life (of Equipment): By mitigating precipitation and abrasion, the product helps extend the service life of feed processing machinery, particularly those involved in liquid mixing and delivery.

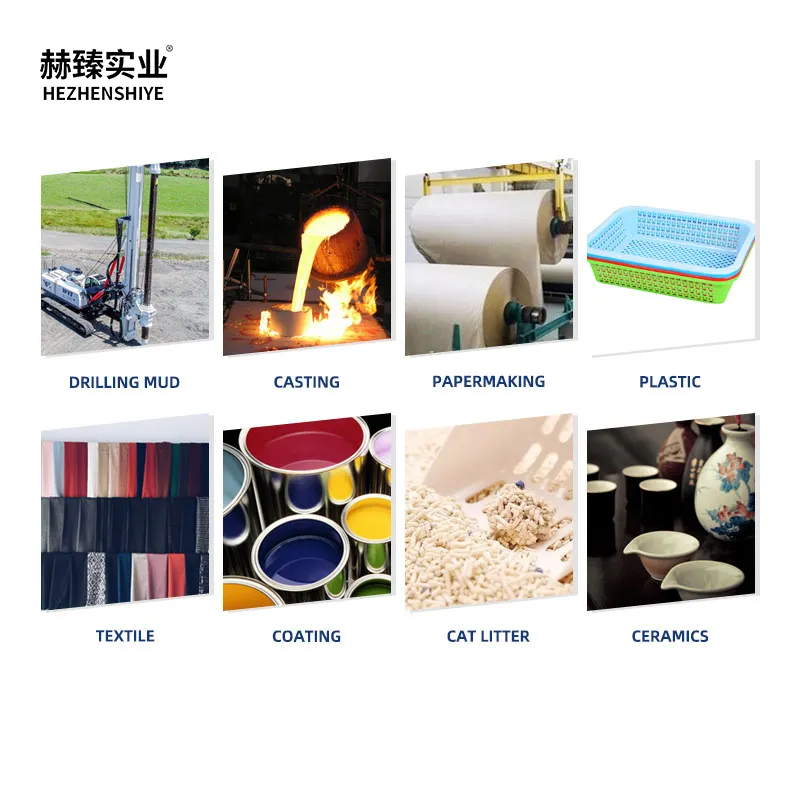

Application Scenarios and Target Industries

The unique properties of Hezhen Sodium-bentonite cast coating feed additive pulping does not precipitate hygroscopic expansion make it exceptionally versatile across various animal nutrition sectors. Its ability to remain suspended in liquid environments while effectively leveraging its natural adsorptive and rheological benefits provides solutions for complex feed formulations.

Key Target Industries:

- Animal Feed Manufacturing: For producers of compound feeds, premixes, and concentrated feeds. The product ensures uniform distribution of bentonite within dry or liquid formulations, contributing to improved pellet quality, anti-caking properties, and mycotoxin adsorption.

- Livestock Farming (Poultry, Swine, Ruminants): Directly used in farm-level feed preparation, especially for liquid feeding systems common in modern swine and poultry operations. Its non-precipitating nature guarantees that animals receive a consistent dose of the additive, crucial for continuous mycotoxin management and gut health.

- Aquaculture: In aquafeeds, maintaining feed stability in water is paramount. The cast coating ensures that the bentonite remains bound within feed pellets, reducing leaching of vital nutrients and maintaining water quality. Furthermore, its inclusion can improve pellet durability during transport and storage, and its unique properties are beneficial for digestive health in aquatic species.

- Pet Food Production: As an anti-caking agent and a source of beneficial minerals, it can improve the texture and shelf-life of pet foods, while also offering mycotoxin binding capabilities.

Typical Application Scenarios:

- Mycotoxin Adsorption in Liquid Feeds: The product's non-precipitating characteristic is vital for liquid feed systems, ensuring uniform dispersion of the adsorbent throughout the feed, maximizing its ability to bind various mycotoxins (e.g., Aflatoxins, Zearalenone, Ochratoxin) efficiently and consistently.

- Digestive Health & Gut Integrity: As a gut conditioner, it supports gut health by stabilizing the intestinal environment, enhancing nutrient absorption, and contributing to better fecal consistency, particularly in young animals or those under stress. The controlled hygroscopic expansion aids in gentle gut cleansing.

- Feed Pellet Quality Improvement: When incorporated into pelleted feeds, it acts as a binding agent, improving pellet hardness, reducing fines, and enhancing feed stability during handling and storage. This leads to reduced feed waste and improved palatability.

- Ingredient Carrier and Flow Agent: Its fine particle size and excellent dispersion properties make it an ideal carrier for other delicate feed ingredients, such as enzymes, probiotics, or vitamins, ensuring their uniform distribution and stability. It also functions as an effective anti-caking agent for various feed materials.

Technical Advantages and Performance Benchmarking

The distinct advantages of Hezhen Sodium-bentonite cast coating feed additive pulping does not precipitate hygroscopic expansion stem from its advanced material engineering and specialized processing. These benefits translate directly into superior performance and economic returns for feed producers and livestock farmers.

Key Technical Advantages:

- Superior Suspension Stability: The "cast coating" technology is pivotal. It modifies the particle surface to minimize inter-particle attraction, ensuring that the bentonite remains homogeneously suspended in water or liquid feed matrices for extended periods without settling or forming hard precipitates. This is crucial for automated dosing systems.

- Optimized Hygroscopic Expansion: While traditional bentonites exhibit uncontrolled swelling that can lead to difficulties in handling and processing, the Hezhen product leverages its hygroscopic expansion in a controlled manner. This allows for effective mycotoxin binding within the gut and improved gut motility without causing undesirable rheological changes in feed slurries.

- Enhanced Bioavailability and Efficacy: The fine, uniformly coated particles offer a maximized active surface area for adsorption of toxins and binding of excess moisture, leading to higher efficacy at lower inclusion rates compared to standard bentonites.

- Reduced Dust and Improved Handling: The specialized processing results in a product with reduced dustiness, improving workplace safety in feed mills and simplifying handling. Its excellent flowability further contributes to ease of use.

- Compatibility with Diverse Formulations: Its neutral interaction with other feed ingredients ensures it does not interfere with the efficacy of vitamins, enzymes, or medications, making it suitable for a wide range of feed formulations.

Product Comparison: Hezhen Advanced Bentonite vs. Standard Bentonite

This comparison highlights that while standard bentonite offers basic benefits, the advanced engineering of the Hezhen product provides a more reliable, efficient, and ultimately more cost-effective solution for modern animal nutrition challenges.

Customized Solutions and Vendor Comparison

Hezhen recognizes that feed formulations and animal production systems are highly diverse. Therefore, we offer not just a premium product but also a commitment to customized solutions and unparalleled customer support, differentiating ourselves from conventional suppliers.

Hezhen's Commitment to Customization:

- Tailored Particle Size: Depending on the application (e.g., fine powder for premixes, larger granules for pelleting, specific suspension characteristics for liquid feeds), Hezhen can adjust the particle size distribution of our Hezhen Sodium-bentonite cast coating feed additive pulping does not precipitate hygroscopic expansion to meet precise client specifications.

- Optimized Coating Profiles: For specialized requirements, such as enhanced binding of specific mycotoxins or controlled release functionalities, our R&D team can work on modifying the "cast coating" agent to achieve desired performance attributes.

- Formulation Integration Support: Our technical experts collaborate with client nutritionists and formulators to seamlessly integrate the product into existing feed matrices, ensuring compatibility and optimizing inclusion rates for maximum benefit. This includes guidance for both dry and liquid feed systems.

- Packaging Options: Flexible packaging solutions, from small bags to large bulk container111s, are available to suit different operational scales and handling requirements.

Vendor Comparison: Why Choose Hezhen?

While the market offers numerous bentonite suppliers, Hezhen stands out through its unwavering commitment to quality, innovation, and customer-centric service:

- Proprietary Technology: Hezhen's "cast coating" and non-precipitating technology is a unique differentiator, providing performance benefits unmatched by generic bentonite suppliers.

- Rigorous Quality Assurance: We exceed industry standards, employing ISO 22000 and HACCP certifications across our production facilities. Each batch undergoes comprehensive testing, ensuring consistency and safety for feed applications.

- Technical Expertise & R&D: Our team comprises material scientists, animal nutritionists, and process engineers dedicated to continuous improvement and developing cutting-edge solutions. We invest heavily in R&D to stay ahead of market demands.

- Global Supply Chain & Reliability: With robust sourcing and logistics, Hezhen ensures reliable supply, efficient order fulfillment, and timely delivery to clients worldwide.

- Long-Term Partnership Philosophy: We view our clients as partners, striving to build enduring relationships through proactive support, problem-solving, and shared success.

Application Case Studies

These case studies illustrate the tangible benefits and successful implementation of Hezhen Sodium-bentonite cast coating feed additive pulping does not precipitate hygroscopic expansion in real-world animal production settings.

Case Study 1: Enhanced Mycotoxin Management in Swine Liquid Feed

- Client: Large-scale swine integrator in Southeast Asia (50,000 sows).

- Challenge: Frequent issues with mycotoxin contamination (DON, Zearalenone) leading to reduced feed intake, reproductive problems, and increased veterinary costs. Traditional bentonite-based binders precipitated in their liquid feeding system, causing uneven distribution and blockages.

- Solution: Hezhen provided a customized formulation of its non-precipitating sodium bentonite, specifically optimized for liquid feed stability, at an inclusion rate of 0.2% in the finisher diet.

- Results:

- 85% reduction in observed precipitation within the liquid feed system.

- 12% increase in average daily gain (ADG) for finisher pigs over a 12-week trial period.

- Significant reduction in incidence of reproductive disorders in breeding sows.

- 25% decrease in feed system maintenance due to reduced clogging.

- Client Feedback: "The stability of Hezhen's product in our liquid feeders is unparalleled. We now have complete confidence in consistent mycotoxin protection, which has directly impacted our bottom line and animal welfare."

Case Study 2: Improved Pellet Quality and Digestibility in Aquafeed

- Client: Leading aquaculture feed producer in Vietnam.

- Challenge: High rates of pellet breakage and fines during transport and handling, leading to feed waste and water quality issues in shrimp ponds. Also sought to improve nutrient utilization.

- Solution: Implemented Hezhen Sodium-bentonite cast coating feed additive pulping does not precipitate hygroscopic expansion at 0.3% inclusion as a binder and gut conditioner in their shrimp feed formulation.

- Results:

- 30% reduction in fines (dust and broken pellets) after transport.

- 15% improvement in water stability of pellets, reducing nutrient leaching.

- Increased FCR by 7% in trial shrimp batches, indicating better nutrient absorption.

- Observed healthier gut morphology and reduced incidence of digestive issues in shrimp.

- Client Feedback: "Hezhen's bentonite has transformed our pellet quality and, more importantly, improved our shrimp health and growth. It's a premium product that delivers measurable results."

Frequently Asked Questions (FAQ)

Q1: What makes Hezhen Sodium-bentonite different from conventional bentonite feed additives?

A1: The key differentiator is our proprietary "cast coating" technology and advanced processing, which ensures the product "pulping does not precipitate hygroscopic expansion." This means it remains suspended homogeneously in liquid feeds, prevents clogging, and offers controlled expansion for optimal efficacy, unlike standard bentonites which often settle and can cause issues in automated systems.

Q2: Is the product safe for all animal species?

A2: Yes, Hezhen Sodium-bentonite is produced under strict quality control (ISO 22000, HACCP) and complies with major international feed safety regulations (e.g., EU, FDA guidelines for feed additives). It is safe for use in poultry, swine, ruminants, aquaculture, and pet food, at recommended inclusion rates.

Q3: How does it contribute to mycotoxin management?

A3: With its high cation exchange capacity (CEC) and engineered particle surface, the product effectively binds a broad spectrum of mycotoxins in the animal's gastrointestinal tract, preventing their absorption and subsequent toxic effects. Its non-precipitating nature ensures consistent delivery of this protection in liquid feed systems.

Q4: Can Hezhen customize the product for specific needs?

A4: Absolutely. We offer customized solutions including tailored particle size, optimized coating profiles for specific binding needs, and flexible packaging options. Our technical team works closely with clients to develop formulations that best suit their unique operational and nutritional requirements.

Logistics, Warranty, and Support

Lead Time and Fulfillment:

Hezhen maintains efficient production and inventory management to ensure prompt order fulfillment. Standard lead time for most orders is 7-14 business days, depending on order volume and specific customization requirements. For large or highly customized orders, a detailed production schedule will be provided upon confirmation. We leverage a global logistics network to ensure timely and cost-effective delivery to your facility.

Warranty Commitments:

Hezhen warrants that all products, including Hezhen Sodium-bentonite cast coating feed additive pulping does not precipitate hygroscopic expansion, meet the specifications outlined in our technical data sheets and certificates of analysis at the time of shipment. Our products are guaranteed to be free from defects in material and workmanship under normal conditions of use and storage. Any claims related to product quality must be reported within 30 days of receipt, accompanied by relevant batch information and supporting documentation.

Customer Support and Technical Assistance:

Our commitment extends beyond product delivery. Hezhen provides comprehensive customer support, including:

- Dedicated Account Management: A designated account manager will be your primary point of contact for all inquiries and support needs.

- Technical Consultation: Access to our team of R&D scientists and animal nutritionists for expert advice on product application, formulation integration, and troubleshooting.

- Regulatory Compliance Guidance: Assistance with understanding and meeting local and international regulatory requirements for feed additives.

- After-Sales Service: Prompt response to any post-delivery queries, product performance reviews, and continuous improvement feedback.

Conclusion and Authoritative References

The innovation embedded in Hezhen Sodium-bentonite cast coating feed additive pulping does not precipitate hygroscopic expansion offers a compelling advantage for feed manufacturers and animal producers seeking to optimize animal health, feed efficiency, and operational stability. Its unique properties, meticulously engineered through advanced processing, address critical challenges posed by traditional bentonite applications, particularly in liquid feed systems and high-performance formulations. By delivering superior suspension stability, controlled hygroscopic expansion, and broad-spectrum mycotoxin adsorption, Hezhen enables partners to achieve higher standards of animal nutrition and economic performance.

Hezhen is committed to driving innovation in animal nutrition, providing not just products, but comprehensive solutions backed by rigorous science, extensive expertise, and a dedication to customer success. Partner with us to unlock the full potential of your feed programs.

Authoritative References:

- Díaz, D. E., & Smith, T. K. (2005). Mycotoxin binders: an overview. Animal Feed Science and Technology, 119(1-4), 1-16.

- EFSA Panel on Additives and Products or Substances used in Animal Feed (FEEDAP). (2017). Scientific Opinion on the safety and efficacy of sodium bentonite for all animal species. EFSA Journal, 15(7), e04910.

- Pasquet, G., Bouix, A., & Lebeau, D. (2018). Bentonite in Animal Nutrition: A Review. Applied Clay Science, 153, 20-30.

- ISO 22000:2018, Food safety management systems – Requirements for any organization in the food chain. International Organization for Standardization.

- Chung, H. Y., & Fan, Y. K. (2020). Advances in Encapsulation Technologies for Feed Additives. Journal of Animal Science and Biotechnology, 11, 25.