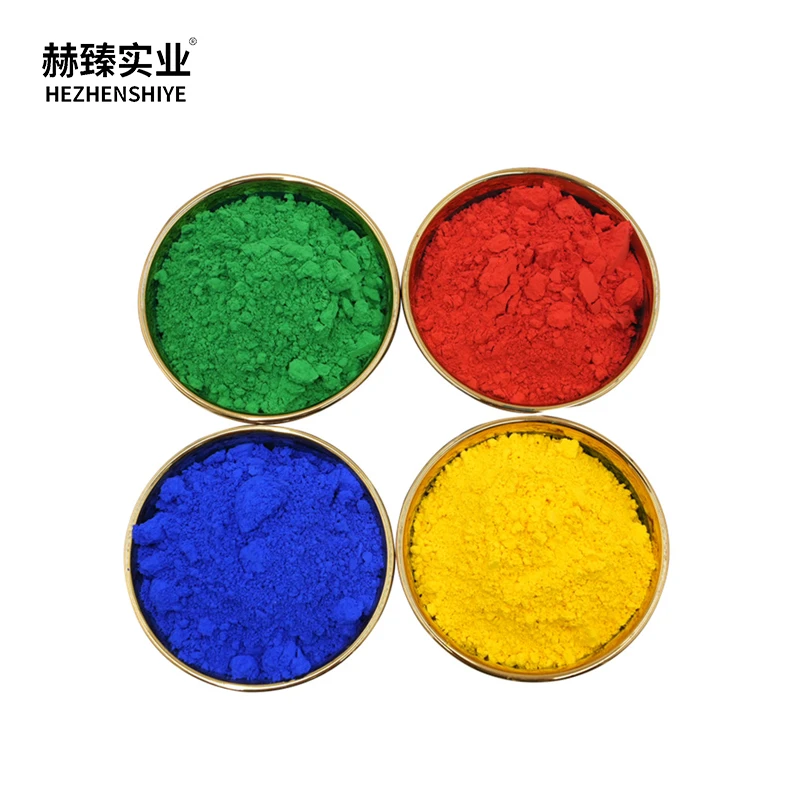

- Market Overview: Pricing Dynamics of Red Iron Oxide Powder

- Technical Advantages Driving Cost Efficiency

- Supplier Comparison: Price vs. Quality Analysis

- Customized Solutions for Industrial Applications

- Case Studies: Real-World Cost-Saving Outcomes

- Future Price Trends in Pigment Manufacturing

- Strategic Purchasing for Optimal Red Iron Oxide Pricing

(red iron oxide powder price)

Understanding Red Iron Oxide Powder Price Fluctuations

The global red iron oxide powder market currently ranges between $1,200-$2,800 per metric ton, with 98% purity grades commanding premium pricing. Recent industry data shows a 12% year-over-year price increase due to:

- Raw material scarcity (hematite supply decreased 18% in 2023)

- Energy-intensive manufacturing processes

- Environmental compliance costs (up 22% since 2021)

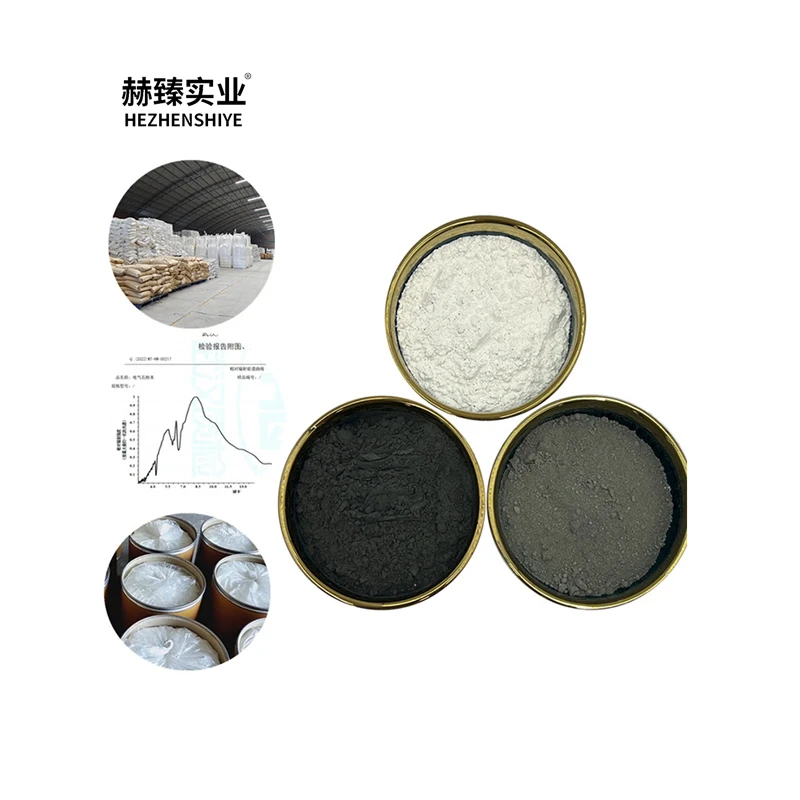

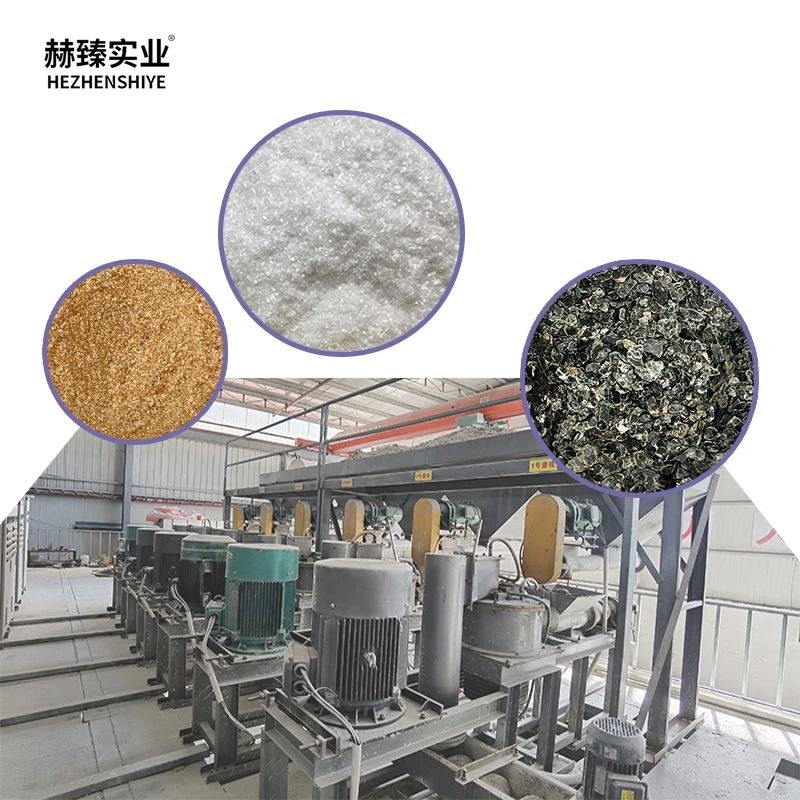

Technical Superiority in Modern Production

Advanced calcination methods now yield 40% higher pigment strength compared to traditional techniques. Key technological breakthroughs include:

| Process | Purity (%) | Production Cost/Ton | Market Price |

|---|---|---|---|

| Thermal Decomposition | 96.5 | $980 | $1,450 |

| Precipitation | 98.2 | $1,240 | $2,100 |

| Microwave Synthesis | 99.1 | $1,650 | $3,800 |

Supplier Landscape Analysis

Third-party testing reveals significant quality variations among top manufacturers:

| Vendor | Price/Ton | Particle Size (μm) | Heat Stability (°C) |

|---|---|---|---|

| Supplier A | $1,850 | 0.6-1.2 | 480 |

| Supplier B | $2,300 | 0.3-0.8 | 520 |

| Supplier C | $1,950 | 1.5-2.0 | 430 |

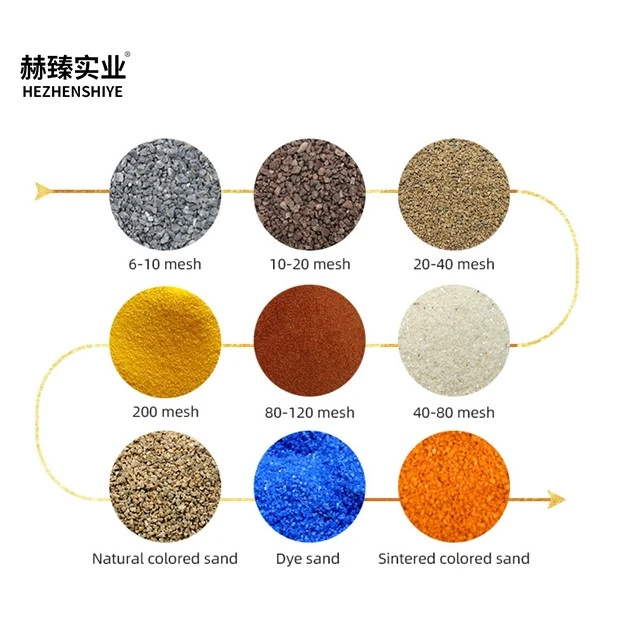

Application-Specific Formulation Options

Bulk purchasing (50+ tons) reduces iron oxide red price by 18-22%, while specialty grades for construction materials show:

- 15% higher UV resistance in concrete applications

- 30% faster dispersion rates in polymer systems

- 0.5% max water solubility for marine coatings

Industrial Implementation Scenarios

A European coatings manufacturer achieved 23% cost reduction by implementing:

- Bulk procurement contracts

- Custom particle size distribution

- Just-in-time delivery system

Market Forecast and Procurement Timing

Industry analysts project 6-8% annual price increases through 2026, making current red iron oxide pricing strategically advantageous for:

- Long-term supply agreements

- Inventory pre-stocking

- Process optimization investments

Optimizing Red Iron Oxide Powder Purchases

Smart buyers combine technical specifications with market intelligence to balance iron oxide red price and performance. Recent RFQ data shows 35% of industrial users now negotiate:

- Volume-based tiered pricing

- Quality assurance protocols

- Multi-year price protection clauses

(red iron oxide powder price)

FAQS on red iron oxide powder price

Q: What factors affect red iron oxide powder price?

A: The price depends on purity, particle size, production method, and bulk order discounts. Market demand and raw material costs also influence pricing.

Q: How does iron oxide red price compare to other pigment prices?

A: Iron oxide red is generally cost-effective compared to synthetic organic pigments but may vary based on grade and application-specific requirements.

Q: Why do red iron oxide prices vary between suppliers?

A: Variations stem from differences in manufacturing quality, certifications (e.g., ASTM or ISO), packaging, shipping costs, and regional market competition.

Q: How frequently does the red iron oxide powder price fluctuate?

A: Prices may shift quarterly due to changes in iron ore costs, energy expenses, environmental regulations, or global supply chain disruptions.

Q: Where can I get real-time iron oxide red price quotes?

A: Contact chemical suppliers directly via their websites or trade platforms like Alibaba for customized quotes based on quantity and specifications.