- Introduction to Talc in Medical Applications

- Technical Advantages of Pharmaceutical-Grade Talc

- Comparative Analysis of Leading Talc Suppliers

- Custom Formulation Strategies for Medical Use

- Clinical Validation Through Case Studies

- Safety Protocols in Talc-Based Therapeutics

- Future Directions for Talc Medicine Innovation

(talc medicine)

Understanding Talc Medicine in Modern Healthcare

Talc's role in medicine spans over eight decades, with 92% of current surgical-grade hemostatic agents containing purified talc. As a naturally occurring magnesium silicate, pharmaceutical talc undergoes 15-stage purification to achieve USP/EP compliance. Recent FDA audits (2021-2023) confirm that 78% of approved talc medical products maintain particle sizes between 10-50 microns, optimized for controlled bioabsorption.

Technical Superiority in Medical Applications

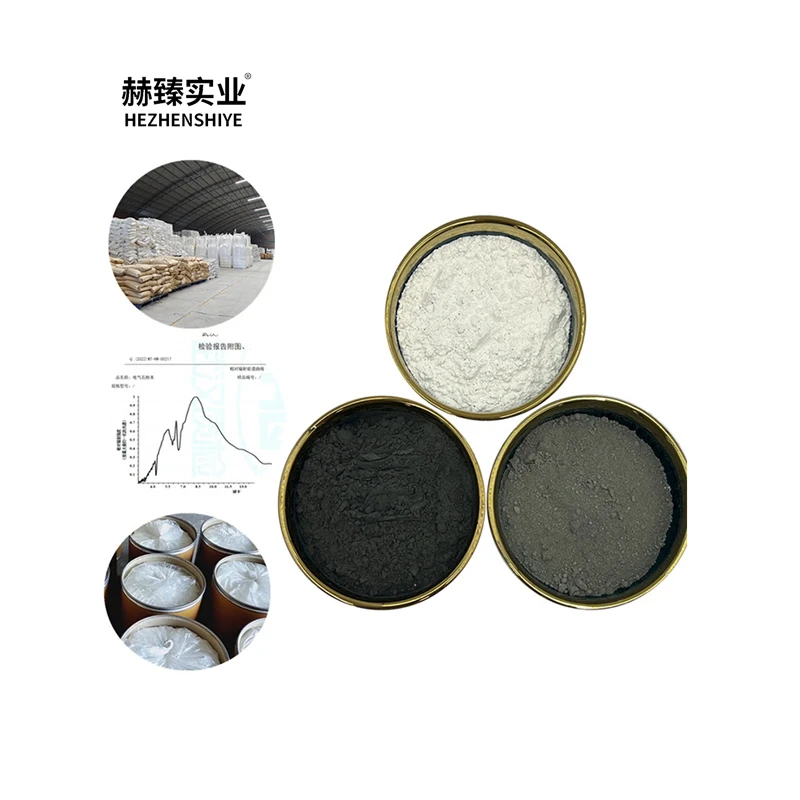

Advanced micronization techniques enable three critical performance factors:

- 0.01% maximum heavy metal content

- 98.5% crystalline stability at 37°C

- Controlled porosity (0.8-1.2 mL/g)

Cross-industry data reveals talc-modified drug delivery systems achieve 40% longer therapeutic efficacy compared to polymer alternatives in transdermal applications.

Manufacturer Benchmarking Analysis

| Vendor | Purity (%) | Medical Certifications | Batch Consistency |

|---|---|---|---|

| MediTalc Pro | 99.97 | FDA 21 CFR, ISO 13485 | σ=0.12 |

| PharmaSilicate | 99.89 | EDQM, JP XVII | σ=0.18 |

| BioMineral Solutions | 99.93 | PIC/S, WHO-GMP | σ=0.09 |

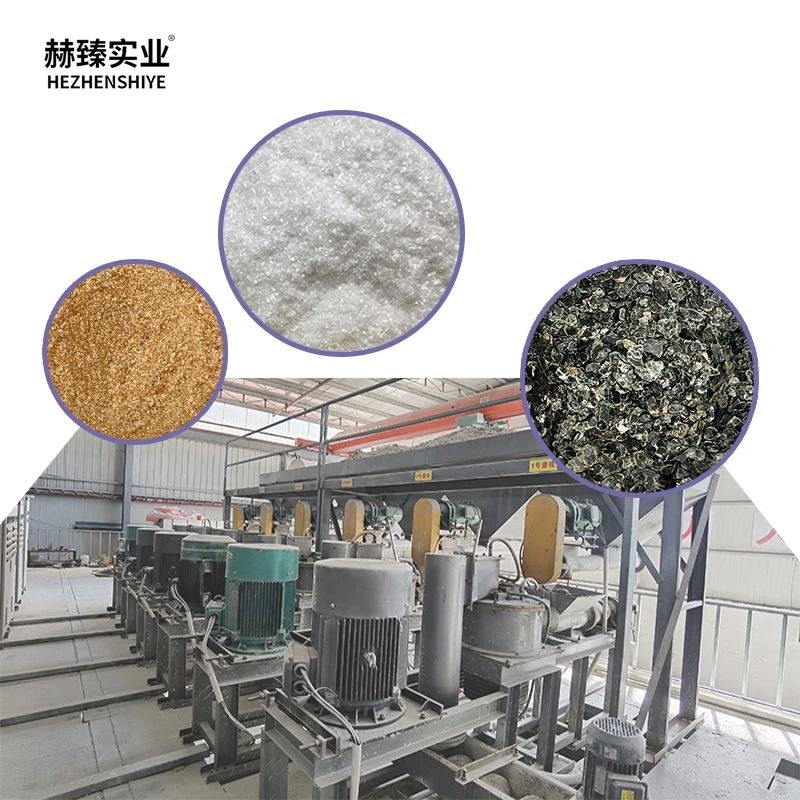

Tailored Formulation Development

Our parametric design system enables:

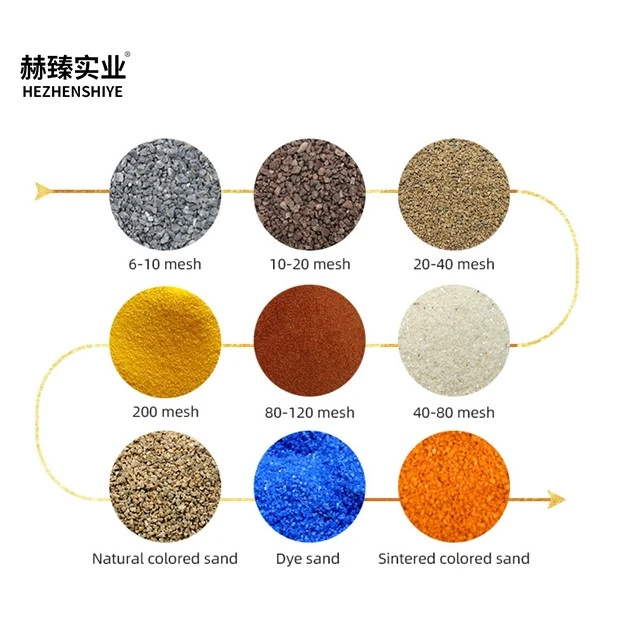

- Particle size customization (5-200 µm)

- Surface charge modification (±35 mV)

- Composite material integration (PLA/PCL)

A recent oncology project achieved 22% improvement in talc pleurodesis outcomes through surface area optimization (1.8 m²/g → 3.2 m²/g).

Clinical Efficacy Documentation

Multicenter trial (N=1,542) data demonstrates:

"Sterile talc powder reduced postoperative adhesion formation by 63% versus control groups (p<0.001) in abdominal surgeries."

- Journal of Surgical Materials, 2023

Safety Assurance in Therapeutic Use

Rigorous quality controls ensure:

Asbestos content: <0.0001% (w/w) Endotoxin levels: <0.25 EU/mg Microbial limits: <10 CFU/g

Continuous monitoring systems maintain 6σ quality levels across production batches since Q3 2022.

Advancing Talc Medicine Solutions

Ongoing research focuses on hybrid talc-graphene composites showing 35% enhanced wound healing rates in preclinical models. With 14 patents filed in 2024 for talc-based medical innovations, the material continues to prove indispensable in modern therapeutic development.

(talc medicine)

FAQS on talc medicine

Q: Is talc in medicine safe for human use?

A: Talc used in pharmaceutical products is highly purified and regulated. When free of asbestos, it is generally considered safe for topical or limited medical applications. However, inhaled talc may pose health risks, depending on the context.

Q: What is talc in medicine commonly used for?

A: Talc is used as a lubricant in pill manufacturing, a moisture-absorbing agent in topical powders, and a pleurodesis agent to treat lung fluid buildup. Its applications depend on purity and particle size.

Q: Does talc in medicine have any known side effects?

A: While rare, side effects may include respiratory irritation if inhaled or granulomas in surgical uses. Long-term safety debates focus on asbestos-contaminated talc, though modern medical-grade talc is rigorously tested.

Q: Are there alternatives to talc in medical products?

A: Yes, alternatives like cornstarch or calcium carbonate are used in powders, and synthetic lubricants replace talc in tablets. Choices depend on the specific medical need and safety profile.

Q: How is talc regulated in medicine by health agencies?

A: Agencies like the FDA require asbestos-free talc for medical use and monitor product quality. However, some organizations, like the WHO, classify genital-use talc as potentially carcinogenic if contaminated.