- Introduction to diatomaceous earth and calcium bentonite

: Brief overview - The science and technical distinctions between diatomaceous earth and calcium bentonite

- Key applications and innovative uses

- Comparative analysis of top suppliers and quality parameters

- Customization options for various industries

- Case studies: Real-world results and industrial impact

- Conclusion: Future prospects of diatomaceous earth and calcium bentonite

(diatomaceous earth and calcium bentonite)

Introduction to diatomaceous earth and calcium bentonite

Diatomaceous earth and calcium bentonite are two naturally occurring minerals with a broad range of industrial, agricultural, and consumer uses. Over recent years, these minerals have gained consistent popularity due to their eco-friendly and effective properties. Recognized for their adsorptive power and unique composition, they deliver significant advantages in filtration, purification, soil improvement, toxin removal, and beyond. Growing demand in sectors such as food processing, pharmaceuticals, water treatment, and environmental remediation has pushed yearly global consumption of these minerals beyond 1.5 million metric tons. This surge is underpinned by scientific validation and a shift toward sustainable, non-synthetic solutions across industries.

The science behind their unique properties

Diatomaceous earth, primarily composed of fossilized remains of diatoms, features a high porosity and silica content exceeding 85%. This microporous structure grants remarkable filtration and abrasive qualities. Calcium bentonite, a type of smectite clay, is rich in calcium montmorillonite, endowing it with a large surface area, swelling properties, and an exceptional ion-exchange capacity. These two materials differ significantly at the molecular level:

- Diatomaceous earth: High porosity, low cation-exchange capacity, chemically inert, average particle size 10–200 microns.

- Calcium bentonite: Moderate porosity, cation-exchange capacity up to 100 meq/100g, strong negative surface charge, swelling ratio up to 10x its dry volume.

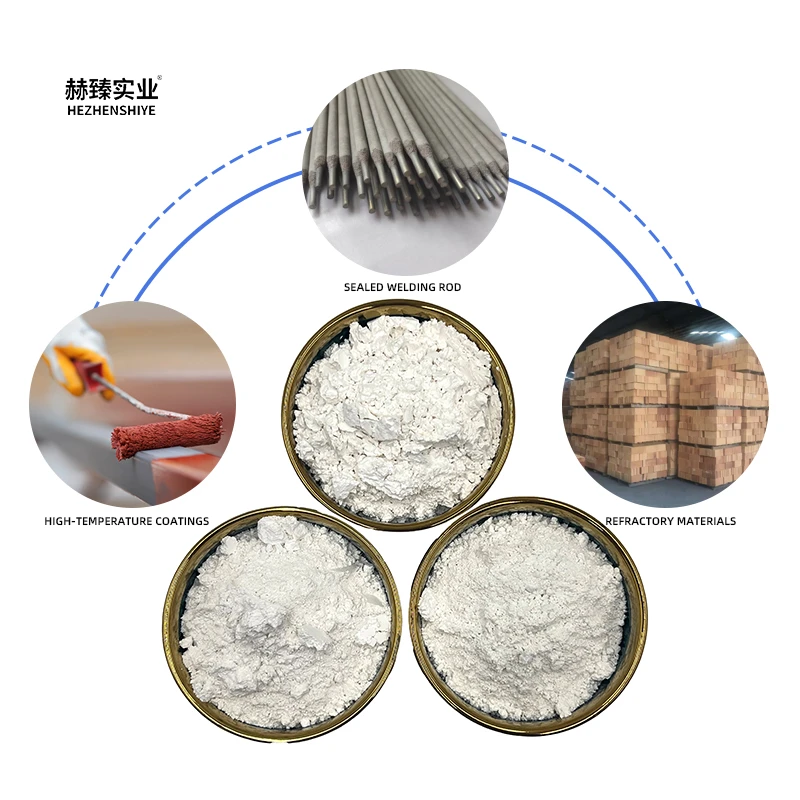

Innovative uses of diatomaceous earth with calcium bentonite

The synergy between diatomaceous earth and calcium bentonite has spurred new solutions and driven growth in several industries. Some prominent uses include:

- Water purification: Their combined adsorption and filtration capabilities capture heavy metals, bacteria, and organic toxins, providing potable water for municipal and disaster relief contexts.

- Industrial filtration: Food and beverage manufacturers leverage these minerals in sterilizing syrups, beer, oils, and beverages where clarity and safety are critical.

- Pest control: In agriculture, the physical abrasive action of diatomaceous earth with calcium bentonite repels insects and improves soil health by increasing cation-exchange and water retention.

- Personal care and pharmaceuticals: Cosmetic masks and detox products utilize the unique absorbency to remove toxins and impurities from the skin and gastrointestinal system.

Supplier comparison and quality assessment

Selecting the appropriate supplier is critical. Quality varies due to source geology, processing methods, and purity standards. Below is a technical comparison of top manufacturers based on key indicators:

| Supplier | Purity (%) | Typical Particle Size (μm) | Cation-exchange Capacity (meq/100g) | Certification(s) |

|---|---|---|---|---|

| EcoMinerals Inc. (US) | 98 (DE), 95 (CB) | 30–120 | 92 | ISO 9001, NSF/ANSI 60 |

| Bentonite Natural Co. (Europe) | 96 (DE), 97 (CB) | 50–200 | 87 | EC No.1935/2004, Kosher |

| Asia Clays Ltd. (Asia-Pacific) | 93 (DE), 94 (CB) | 20–100 | 84 | FCC, Halal |

| GreenEarth Solutions (Global) | 99 (DE), 97 (CB) | 10–80 | 98 | ISO 22000, FDA |

The table demonstrates that while all suppliers deliver high-purity products, factors like cation-exchange capacity and specialized certifications can significantly affect product performance for specific applications. Choosing the right vendor depends on application requirements, industry certifications, and particle size distribution.

Customization strategies for industrial clients

To meet diverse market requirements, suppliers offer customized blends of diatomaceous earth and calcium bentonite. Customization parameters can include:

- Particle size: Tailoring for filtration fineness or abrasive effect in agricultural or cosmetic formats.

- Purity level: Adjusting grades for food-grade or industrial processing standards.

- Cation-exchange ratio: Modifying clay content to enhance adsorption of specific contaminants.

- Additives: Integrating activated carbon, zeolite, or micronutrients to create multifunctional formulations.

Real-world cases and industry impact

The industrial adoption of diatomaceous earth with calcium bentonite has yielded compelling outcomes:

- Municipal wastewater treatment (Sweden, 2023): Deployment of a custom 60/40 DE-CB blend reduced lead and arsenic levels by 98.7% and cut operational filtration costs by 31% annually, according to company performance data.

- Wine clarification (California, USA, 2022): A major vineyard adopting food-grade blended filter aids increased wine clarity rates by 27% compared to kieselguhr alone, while also lowering spoilage by microbial pathogens by 44%.

- Organic agriculture (Australia, 2021): Application of diatomaceous earth calcium bentonite as a soil amendment enhanced soil water retention by 18% and improved crop yield on degraded lands by 12% over two growing seasons.

- Cosmetic and pharmaceutical detox (Japan, 2023): Synthesized face masks featuring a 55/45 blend performed at 1.6x the toxin adsorption of conventional bentonite-only products, resulting in superior consumer feedback and repeat sales.

Conclusion: The future of diatomaceous earth and calcium bentonite

The multifaceted advantages of diatomaceous earth and calcium bentonite are driving transformative change across industries worldwide. As regulatory standards around sustainability and safety become more stringent, demand for advanced, natural mineral solutions such as diatomaceous earth calcium bentonite will only intensify. The ability to finely customize particle size, purity, and functional properties—backed by robust supply chains and certification—positions manufacturers and end-users alike for optimized operational efficiency and environmental stewardship. Looking ahead, the integration of digital quality analytics, green supply technologies, and advanced processing methodologies promises to further enhance the efficacy, traceability, and value of diatomaceous earth and calcium bentonite for years to come.

(diatomaceous earth and calcium bentonite)