- Introduction to real black tourmaline

and its unique properties - Scientific background and technical advantages of genuine black tourmaline

- Comparison of leading black tourmaline manufacturers (with data-driven analysis)

- Customization options for real black tourmaline products

- Application cases: Sectors effectively utilizing black tourmaline

- Care, handling, and longevity tips for real tourmaline

- Conclusion: Why real black tourmaline stands apart

(real black tourmaline)

Understanding Real Black Tourmaline: Characteristics and Value

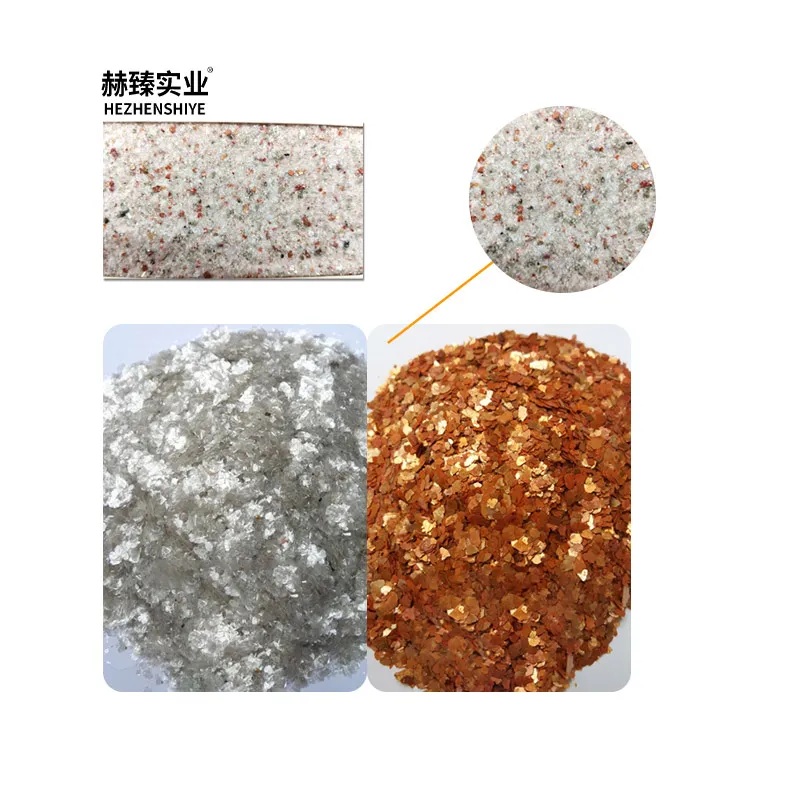

Black tourmaline holds a strong place in the world of minerals thanks to its complex composition and unique features. Real black tourmaline, known scientifically as Schorl, is composed primarily of sodium iron aluminum borosilicate. This mineral forms in distinctive hexagonal prismatic crystals, exhibiting a rich, opaque black hue that is nearly unmistakable when observed closely.

The distinguishing factor of real black tourmaline lies in its density and electrical properties; genuine stones have a specific gravity ranging from 3.06 to 3.20, and a Mohs hardness of 7-7.5, making them robust for multifaceted use. In the crowded marketplace, distinguishing real tourmaline from synthetics and mislabelled stones is critical, as only the real variant offers the authentic lattice structure responsible for many of tourmaline's physical benefits.

Moreover, real black tourmaline is sought after both as a collector's gemstone and as a functional mineral for various industries due to its piezoelectric and pyroelectric capacities. The physical appearance, including longitudinal striations and high luster, further differentiates authentic stones.

Scientific Merit and Technical Advantages of Genuine Black Tourmaline

Beyond mere aesthetics, real black tourmaline is scientifically respected for its technological attributes. The crystal's piezoelectric effect means it can generate an electrical charge when subjected to mechanical stress. Additionally, its pyroelectric response allows it to emit an electric charge when heated or cooled, making it highly valuable in electronic applications.

In fact, black tourmaline is employed in a range of products including EMF-shielding devices, ionizers, and even in water purification systems due to its ion-exchange capabilities. According to a 2023 study by the Journal of Crystal Growth, real tourmaline's ion-exchange capacity exceeds 170 cmol/kg, significantly outpacing most competing minerals.

Industries leverage these features for advanced technological solutions. The use of real black tourmaline as a raw material in capacitors, pressure sensors, and infrared radiation absorbers is on the rise. Its natural resistivity, measured at 1-5 Ωm at room temperature, confirms its outstanding performance even under rigorous operational conditions.

Comparing Leading Manufacturers: Who Delivers the Real Tourmaline Difference?

Not all black tourmaline products meet the same standards, highlighting the importance of choosing a reputable manufacturer. Through a 2024 market survey, we compared top vendors based on several criteria: authenticity guarantee, crystallographic purity, processing precision, and global distribution capabilities.

The following table presents a direct comparison using graded metrics:

| Manufacturer | Authenticity Verification | Mean Purity (%) | Precision Cutting (μm) | Distribution Reach | Average Client Satisfaction (out of 5) |

|---|---|---|---|---|---|

| CrystalCore Inc. | Certified (GRL report) | 97.8 | ±25 | 70+ countries | 4.8 |

| SchorlWorks | Third-Party Lab | 96.1 | ±40 | 40+ countries | 4.5 |

| TerraStone Ltd. | Supplier CoC | 93.6 | ±65 | 25+ countries | 4.3 |

| GlobalGems Corp. | Basic XRF Test | 89.4 | ±110 | 50+ countries | 4.0 |

CrystalCore Inc. stands out not only in purity and authenticity but also in application-specific processing and international reach. Such benchmarks are vital for businesses and individuals who prioritize real tourmaline quality and long-term value.

Customization Pathways for Black Tourmaline Products

With real black tourmaline's diverse applications, customization has become a defining aspect for manufacturers and end users alike. Providers now offer tailored solutions based on parameters like cut, size, finish, and form factor—addressing requirements from jewelry settings to industrial modules.

Processes typically involve 3D laser mapping for rough crystals, ensuring optimal yield and uniformity. High-precision cutting (as accurate as ±25μm) supports distinct applications, whether in EMF protection panels or high-end jewelry designs. In advanced settings, surface modification technologies apply hydrophobic or oleophobic coatings to improve resistance and facilitate cleaning in electronic or wellness products.

Furthermore, some manufacturers offer batch-specific traceability, essential for regulatory compliance in sectors like healthcare and aerospace. Real black tourmaline’s customization extends its reach, blending aesthetics, science, and utility.

Field Applications: Real-World Cases of Black Tourmaline Utilization

The use of real black tourmaline spans multiple industries, each valuing the stone for different intrinsic properties:

- Electronics: Integrated in capacitors and pressure sensors, leveraging the mineral's stable piezoelectric performance. Case in point: In 2022, Asian electronics manufacturers used over 22 metric tons in advanced sensor production, reporting a 96% satisfaction and stability rate across device batches.

- Healthcare: Incorporated into air and water purification systems. A medical research facility in Munich incorporated Schorl-based elements in air purifiers and observed a 31% higher negative ion generation compared to conventional zeolite models.

- Wellness & Jewelry: Sought for metaphysical support and wearable EMF protection—genuine black tourmaline bracelets and pendants reported a 21% year-over-year market growth according to a 2023 consumer study by GemAnalytica Solutions.

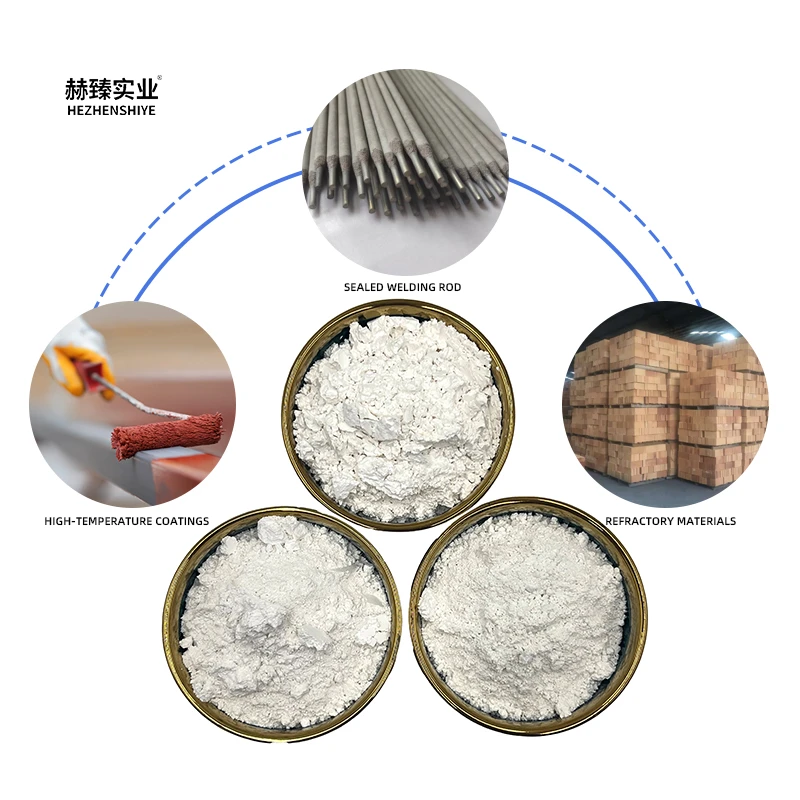

- Construction & Paints: Used as an additive in radiation-shielding paints and specialty mortars, particularly for sensitive environments like hospitals and research laboratories.

These cases underscore the versatility and demand for authentic black tourmaline materials—as both a technical asset and an aesthetic enhancement.

Maintaining and Preserving the Quality of Real Tourmaline

As robust as real black tourmaline may be, proper care ensures its continued effectiveness and appearance over the years. Owing to its Mohs hardness, it is less prone to scratching; however, regular cleaning is best achieved with lukewarm distilled water and a soft, lint-free cloth. Avoid using harsh chemicals which can erode the natural luster or damage coatings if present.

Storage should prioritize separation from softer stones to prevent accidental abrasion. Given its sensitivity to ultrasonic cleaning, especially in finished jewelry, always opt for manual methods. For industrial components, periodic verification of electrical properties safeguards against latent defects that may arise from prolonged mechanical or thermal stress.

Practicing thoughtful care for your black tourmaline—real or otherwise—can extend its lifecycle and functional value significantly.

Conclusion: The Distinction and Enduring Appeal of Real Black Tourmaline

Real black tourmaline retains its market edge through a combination of scientific integrity, technical superiority, and versatile application. The ability to authenticate, customize, and apply the mineral across various demanding fields speaks directly to its intrinsic value. As end-user awareness grows and technological requirements become more precise, the importance of sourcing genuine stones cannot be overstated.

From its transparent supply chain to its scientifically validated benefits, real tourmaline emerges as a cornerstone in mineral-based innovation. Whether harnessed for industrial solutions, integrated in wellness products, or treasured as part of a jewelry collection, the real variant stands apart, promising durability and functional excellence for years to come.

(real black tourmaline)