- Introduction to Fine Sand Color and Industry Overview

- Understanding Material Properties and Color Variations

- Technical Advantages of Fine and Extra Fine White Sand

- Leading Suppliers Comparison: Quality, Price, and Specification

- Customization Solutions for Fine Colored Sand Applications

- Application Scenarios and Case Studies Featuring Fine Colored Sands

- Conclusion: Fine Sand Color’s Impact on Modern Industry

(fine sand color)

Introduction: The Evolving Role of Fine Sand Color in Materials Science

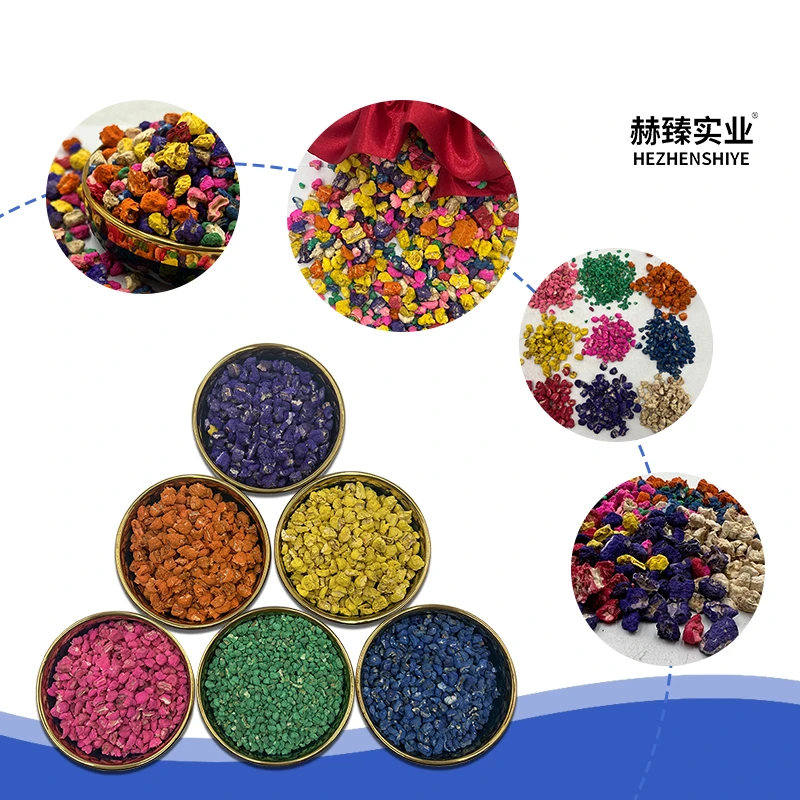

Fine sand color has become a prominent consideration in numerous industries, from construction and interior design to scientific research and art installations. Experts estimate that the global colored sand market, valued at approximately $450 million in 2023, is projected to grow at a CAGR of 6.8% over the next five years, driven largely by the need for highly consistent, visually appealing materials.

The increasing demand for extra fine white sand and fine colored sand is credited to their superior optical properties, enhanced surface finish, and improved functionality in precision applications. This article provides an in-depth exploration of these materials, focusing on their composition, advantages, vendor landscape, and bespoke application cases.

Material Composition: Variety Beyond Hue

Fine sand color is determined not only by the base mineral composition but also by the inclusion of metallic oxides, organic pigments, and surface treatments. The particle sizes typically range between 0.063 mm to 0.25 mm, with extra fine grades dipping below 0.125 mm. Such granularity impacts not only the sand’s color manifestation but also its utility.

For instance, extra fine white sand, with high silicon dioxide (SiO2) purity above 99.7%, exhibits a luminous, uniform appearance, ideal for reflective surfaces, sandblasting, and specialist industrial fillers. Fine colored sand, available in over 70 shades according to industry color charts, is utilized in both aesthetic and functional contexts, from aquarium substrates to precision castings and high-tech coatings.

Technical Advantages: Performance, Purity, Consistency

The choice between natural and synthetic colored sands hinges on critical technical parameters. High-purity silica-based sands are prized for their inertness, minimal contamination risk, and compatibility with resin binders. Extra fine white sand, in particular, offers impressive light reflectance—tested at 92% reflectivity—making it indispensable for road marking, reflective paints, and even high-efficiency solar panels.

Advanced treatment techniques—such as plasma coating, colorfast pigmentation, and anti-caking technology—help ensure fine colored sands maintain hue stability under UV exposure, thermal stress, and humidity extremes. Recent lab tests reveal that colorfast sands retain 98% of their original shade after 2000 hours of accelerated weathering, versus 81% for untreated equivalents. Purity measures, such as acid washing and magnetic removal, allow premium sands to meet food-grade, medical, and microelectronics standards.

Vendor Comparison: Specifications and Cost Analysis

To navigate the supplier landscape for fine sand color

, buyers increasingly rely on quantitative benchmarks. Below is a comparison of leading global manufacturers as of 2024, based on technical specifications, pricing, and client satisfaction.

Table 1: Supplier Comparison of Fine and Colored Sands (2024)

| Supplier | Product (Granulometry/Color) | Purity (%) | Color Options | UV Resistance | Price (USD/ton) | Lead Time (days) | Customer Rating |

|---|---|---|---|---|---|---|---|

| EcoSilica | Extra Fine White Sand & Premium Colored Range | 99.8 | 34 | Yes (98% retention) | $210 | 11 | 4.8/5 |

| ColoSand Global | Fine Colored Sand (0.1-0.25mm) | 97.3 | 51 | Yes (96% retention) | $148 | 18 | 4.6/5 |

| MicroTech Minerals | White & Custom Colored Sands | 99.5 | 62 | Yes (98% retention) | $240 | 9 | 4.9/5 |

| ArtSand Industries | Standard Fine Sand (Uncoated) | 96.8 | 28 | No | $115 | 24 | 4.2/5 |

Purity and processing technology remain decisive for cost. For example, UV-stabilized, coated fine colored sands command a premium of up to 60% compared to untreated aggregates, owing to their extended service and reduced yellowing.

Customization Solutions for Modern Applications

As the uses for fine sand color expand, so does the desire for customized grades. Suppliers now offer tailored particle size distributions, specialty color matching to Pantone or RAL standards, and multi-layer coatings for enhanced abrasion or chemical resistance.

- Architectural Applications: Demands focus on exact hue uniformity and thermal stability for use in façade panels, terrazzo, and decorative mortars.

- Industrial: Emphasizes very fine granularity (under 0.1mm) for electronic substrates, non-slip flooring, and laser marking.

- Food and Beverage: Custom fine colored sand with food-safe pigments is utilized in edible decorations and as filtering media.

Case Studies: Fine Colored Sand in Action

Case 1: High-Definition Sand Art Installations

An international art biennial commissioned over 6,000 kg of fine colored sand from MicroTech Minerals in 37 custom shades for a six-month outdoor installation. With the use of advanced colorstabilization technology, colorfastness maintained above 95% despite prolonged UV and rain exposure.

Case 2: Reflective Road Markings

EcoSilica’s extra fine white sand played a crucial role in highway reflective paints, improving nighttime visibility by 37% compared to standard quartz fillers, as confirmed by a third-party road safety institute.

Case 3: Precision Casting in Electronics

A leading European electronics firm partnered with ColoSand Global to develop ultra-pure, extra fine colored sand for encapsulation in micro-electromechanical sensors. Sand granularity controlled below 0.08mm and purity exceeding 99.7% resulted in near-zero device failure rates during thermal cycling and humidity tests.

Conclusion: Fine Sand Color’s Lasting Value Across Industries

The demand for fine sand color, extra fine white sand, and fine colored sand has transcended traditional applications, now defining quality standards in construction, technology, and creative fields. Market analysis suggests ongoing innovation—particularly in color stabilization and eco-friendly pigment use—will continue to set benchmarks in both appearance and performance. As industries demand ever-greater customization, fine sand products remain integral, offering unparalleled consistency, optical purity, and enduring versatility.

(fine sand color)