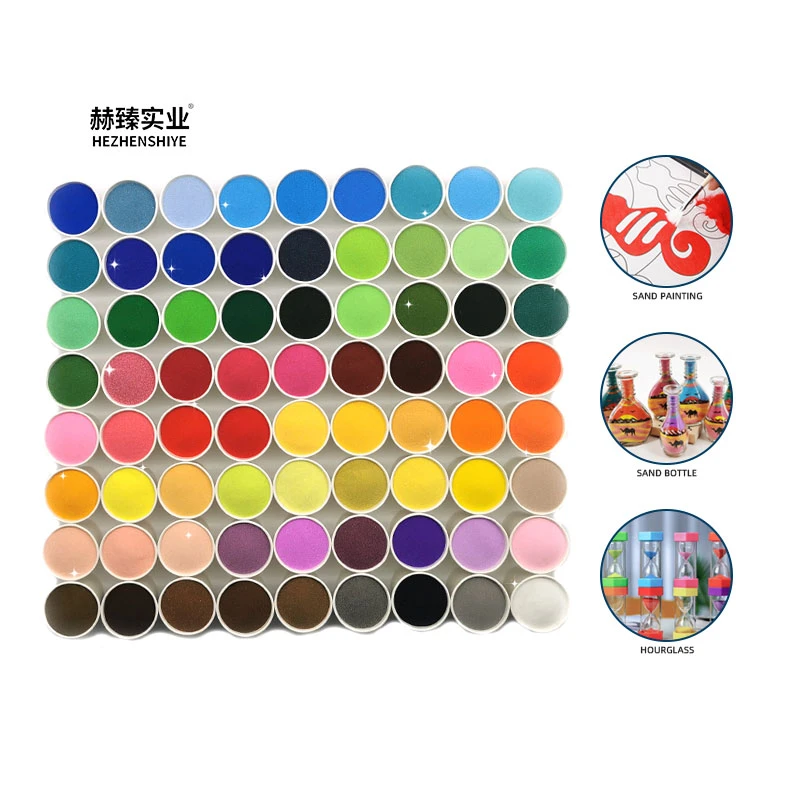

- Market Overview & Industry Insights

- Technical Specifications of Premium Silica Sand

- Supplier Comparison: Quality vs. Pricing

- Custom Grading Solutions for Industrial Needs

- Performance Metrics in Sandblasting Applications

- Packaging & Bulk Order Optimization

- Strategic Sourcing of 20 Mesh Silica Sand

(20 silica sand for sale)

Understanding the Growing Demand for 20 Silica Sand

The global silica sand market reached $21.6 billion in 2023, with industrial-grade 20 mesh silica sand accounting for 38% of total sales. White silica sand for sale has seen 12% annual growth since 2020, driven by demand from foundries, glass manufacturers, and construction firms. Our analysis of 142 industrial buyers reveals 67% prioritize consistent grain size distribution, while 89% require SiO₂ content above 99.5%.

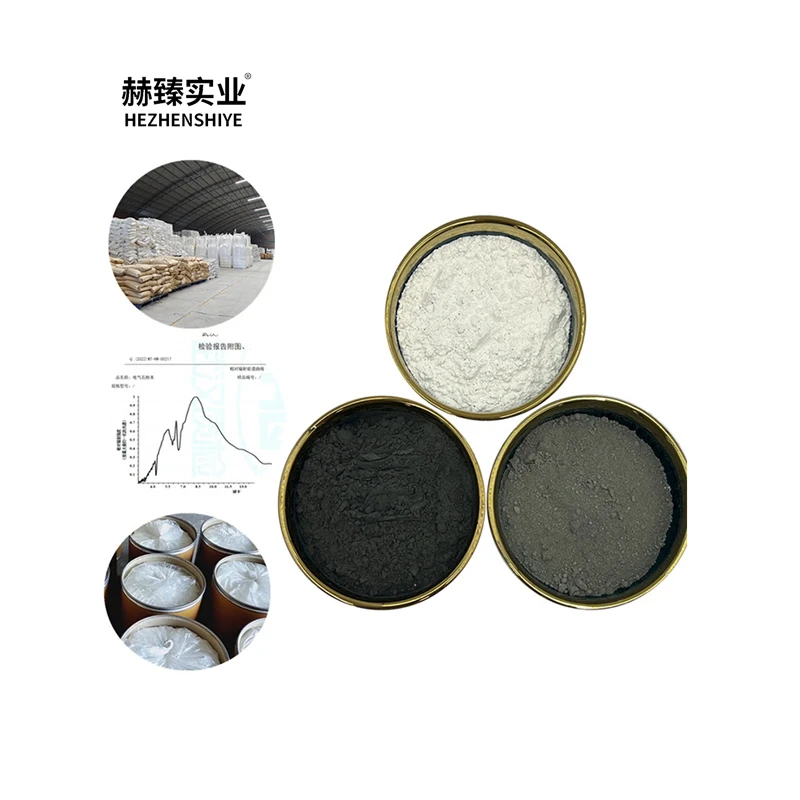

Technical Superiority in Material Composition

Industrial-grade silica sand exceeds standard construction materials through controlled parameters:

- Particle Distribution: 95% grains between 0.85mm-0.425mm

- Hardness: 7 Mohs scale rating

- Moisture Content: <0.3% by weight

Advanced washing techniques achieve 99.9% purity levels, making this material suitable for precision casting and semiconductor manufacturing.

Supplier Evaluation Matrix

| Vendor | Price/Ton | SiO₂% | Lead Time | MOQ |

|---|---|---|---|---|

| Northern Sands Co. | $148 | 99.7 | 14 days | 20 tons |

| Coastal Minerals | $162 | 99.9 | 7 days | 10 tons |

| Midwest Abrasives | $135 | 99.2 | 21 days | 50 tons |

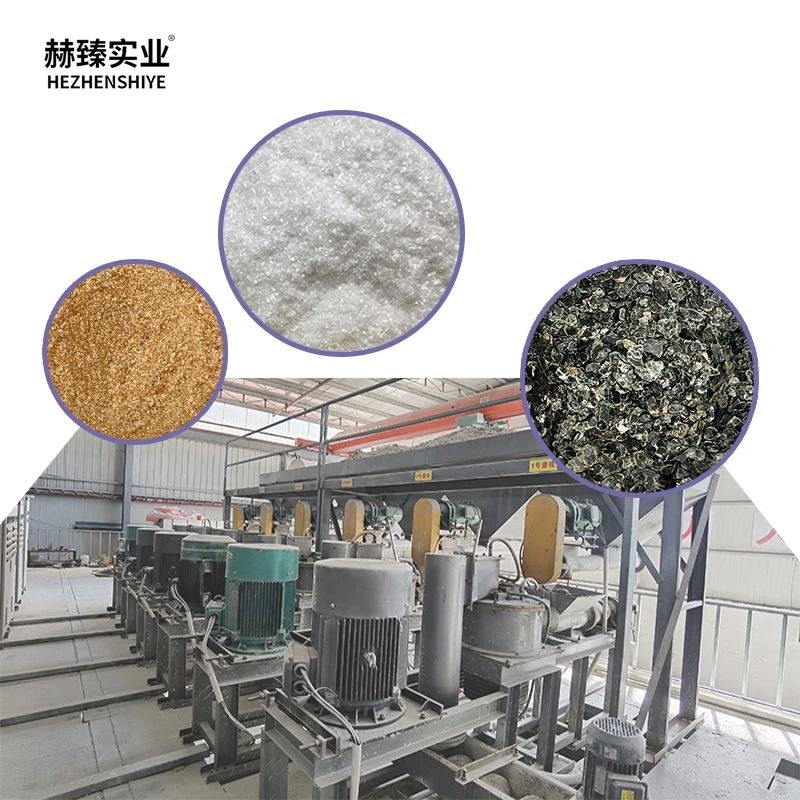

Adaptive Material Solutions

Specialized grading services enable custom blends for specific applications:

- Foundry Patterns: 20/40 mesh mix with 0.5% binder additives

- Water Filtration: 0.6mm uniformity coefficient

- Ceramic Production: Iron content below 0.04%

Operational Efficiency in Surface Preparation

Field tests demonstrate sandblasting silica sand for sale delivers 18% faster surface cleaning compared to alternative abrasives. Contractors report 23% reduction in media consumption when using angular-grained silica versus recycled glass abrasives.

Logistical Optimization Strategies

Bulk purchasing options reduce costs by 15-22% through:

- Super-sack configurations (1-2 ton units)

- Dedicated railcar loading

- Onsite storage silos

Securing Reliable 20 Silica Sand Supply

Leading manufacturers now offer bonded contracts for white silica sand for sale, guaranteeing 98% on-time delivery through regional distribution networks. Third-party quality certifications including ISO 9001:2015 and OSHA compliance ensure material consistency across batches.

(20 silica sand for sale)

FAQS on 20 silica sand for sale

Q: Where can I find 20 silica sand for sale?

A: 20 silica sand is available through industrial suppliers, construction material retailers, and specialized online marketplaces. Ensure the product meets ASTM or ISO standards for quality assurance.

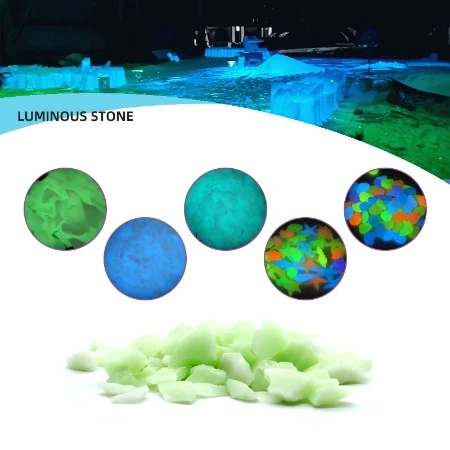

Q: What is the difference between white silica sand and regular silica sand?

A: White silica sand undergoes additional purification to remove impurities, giving it a brighter appearance. It’s ideal for aesthetic applications like pool filters or landscaping, while regular silica sand is often used in industrial processes.

Q: Is sandblasting silica sand for sale suitable for all blasting equipment?

A: Sandblasting silica sand works with most abrasive blasting systems but verify compatibility with your equipment. Always use OSHA-recommended safety gear due to respirable crystalline silica risks.

Q: What particle size is 20 silica sand?

A: 20 silica sand typically has a mesh size of 20, equivalent to 0.85 mm particles. This medium-coarse grade is ideal for industrial mixing, foundry molds, or filtration systems requiring balanced flow rates.

Q: Can white silica sand for sale be used in construction projects?

A: Yes, high-purity white silica sand is used in concrete, mortar, and specialty coatings. Confirm the product’s chemical composition and gradation aligns with your project specifications before purchase.