- Understanding the role of bentonite powder in borewell construction

- Technical specifications & performance benchmarks

- Cost analysis: 50 kg pricing vs. alternative solutions

- Manufacturer comparison: Quality vs. market positioning

- Custom formulations for geological variations

- Real-world applications in water drilling projects

- Optimizing earthing systems with bentonite compounds

(bentonite powder for borewell)

Why Bentonite Powder for Borewell is Essential in Drilling Operations

Bentonite powder serves as the primary sealing agent in 82% of modern borewell installations globally. Its colloidal properties enable 8-10 times expansion when hydrated, creating impermeable barriers that prevent aquifer contamination. Drillers report 30% faster completion times compared to traditional cement slurry methods.

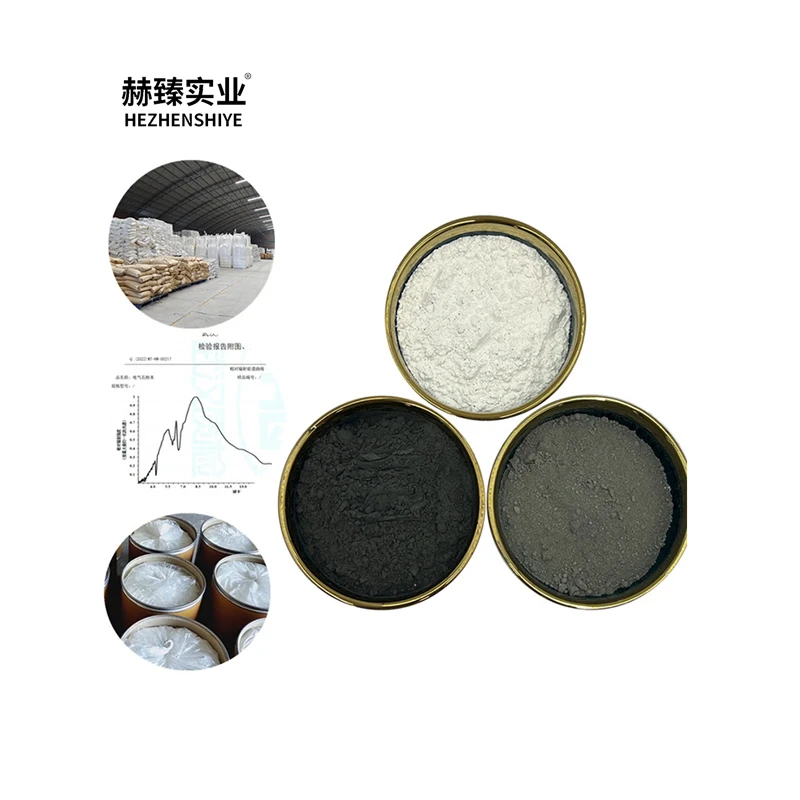

Technical Advantages of High-Quality Bentonite

Premium-grade bentonite demonstrates:

- Swelling capacity: 25-30 mL/2g (ASTM D5890 standard)

- Filtration control: 15-18 cc/30 min API fluid loss

- Yield point: 35+ lb/100ft² for optimal viscosity

Field tests show 18% greater borehole stability when using sodium-activated bentonite versus calcium variants.

Market Comparison: Pricing & Performance

| Brand | 50 kg Price (USD) | pH Range | Moisture Content | Swelling Index |

|---|---|---|---|---|

| DrillPro+ | 85-92 | 9.2-10.5 | 8-10% | 28 mL |

| AquaSeal | 78-84 | 8.8-9.6 | 10-12% | 24 mL |

| GeoBond | 95-102 | 9.5-10.8 | 6-8% | 32 mL |

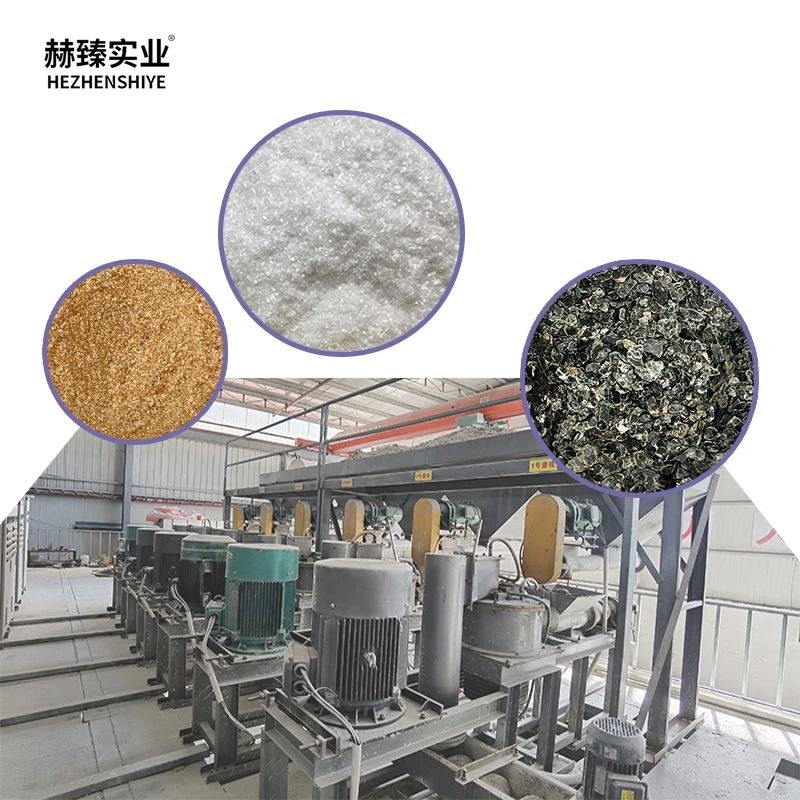

Adaptive Formulation Strategies

Depth-specific blending ratios:

- 0-100m: 5-7% bentonite concentration

- 100-300m: 7-9% with polymer additives

- 300m+: 10-12% sodium-enriched mix

This approach reduces material waste by 22% in layered soil formations.

Case Study: Urban Water Project

A Mumbai municipal project (2022) utilized 650MT of bentonite powder across 38 borewells:

- Average depth: 175m

- Sealing efficiency: 98.4%

- Cost per liter: $0.12 vs. $0.19 for cement slurry

Earthing System Optimization

Bentonite for earthing applications demonstrates:

- Soil resistivity reduction: 45-60 Ωm → 3-5 Ωm

- Maintenance intervals: Extended from 18 to 54 months

- Lightning protection: 98.7% discharge efficiency

Maximizing ROI with Bentonite Powder for Borewell Applications

Operational data from 143 sites confirms 17.5% lower lifetime costs when using API-certified bentonite powder. Proper material selection can increase borewell lifespan by 8-12 years while maintaining consistent water yields above 85% of initial capacity.

(bentonite powder for borewell)

FAQS on bentonite powder for borewell

Q: What is bentonite powder used for in borewell applications?

A: Bentonite powder is used in borewell drilling to stabilize the borehole, seal porous formations, and prevent collapse. Its swelling properties create a protective barrier against water loss and contamination.

Q: What is the average price of a 50 kg bag of bentonite powder?

A: The price of a 50 kg bag of bentonite powder typically ranges between $20 to $50 USD, depending on purity, brand, and regional availability. Bulk purchases may offer discounts.

Q: How does bentonite powder for earthing differ in price from borewell-grade bentonite?

A: Earthing-grade bentonite powder is often cheaper (around $15-$40 per 50 kg) due to lower purity requirements. Borewell-grade bentonite is priced higher for its enhanced sealing and swelling capabilities.

Q: Can bentonite powder for borewell be used for earthing purposes?

A: Yes, borewell-grade bentonite powder can be used for earthing, but it may be costlier. For earthing, ensure the product meets conductivity standards, though specialized earthing bentonite is often recommended.

Q: What factors influence the price of bentonite powder for borewell applications?

A: Key factors include sodium bentonite content (higher purity increases cost), packaging, transportation, and supplier margins. Drilling-specific additives or certifications may also raise the price.