Industry Trends in High-Performance Insulation Materials

The global industrial landscape is experiencing a significant shift towards materials offering superior thermal, electrical, and chemical resistance, driven by stringent operational demands and the imperative for enhanced energy efficiency. Industries such as papermaking, metallurgy, petrochemicals, and power generation are continuously seeking innovative solutions to optimize processes, reduce downtime, and extend equipment lifespans. This demand is particularly acute for high-temperature insulation materials that can withstand extreme environments while maintaining structural integrity and performance. Advancements in ceramic and composite material science, specifically leveraging natural minerals like mica, are paving the way for a new generation of robust, long-lasting industrial components that not only meet but exceed traditional material limitations. The emphasis on sustainability and operational cost reduction further fuels the adoption of such advanced solutions, positioning specialized ceramics as critical enablers for modern industrial innovation.

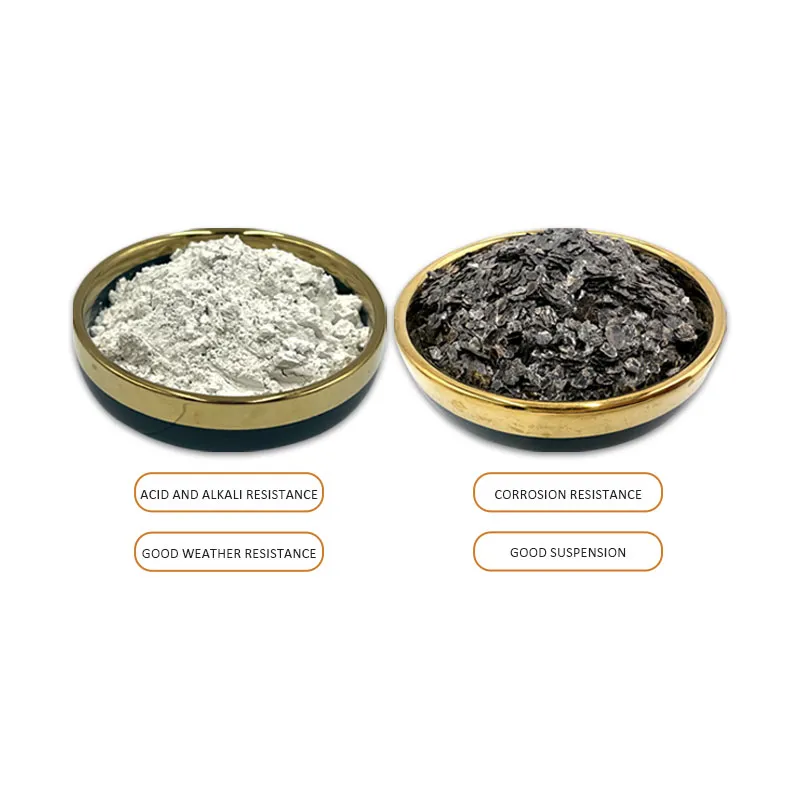

Product Overview and Technical Specifications

Introducing Hezhen papermaking ceramics using mica powder calcined mica sheet insulation high temperature resistant material, an advanced composite ceramic engineered to provide exceptional performance in demanding industrial applications. This innovative material combines the inherent thermal stability and electrical insulation properties of calcined mica with the robust mechanical and chemical resistance of specialized ceramic matrices. The result is a high-performance solution that offers unparalleled insulation capabilities, high-temperature resistance, and dimensional stability, making it ideal for critical components in various heavy industries. Its unique formulation ensures long-term reliability and efficiency, significantly outperforming conventional insulation materials in harsh operating conditions.

Key Technical Parameters:

| Parameter | Specification |

|---|---|

| Max. Operating Temperature | Up to 1200°C continuous |

| Dielectric Strength (ASTM D149) | >20 kV/mm |

| Thermal Conductivity (at 500°C) | 0.2 – 0.5 W/(m·K) |

| Compressive Strength (ISO 10061) | 200 – 350 MPa |

| Density | 2.5 – 2.8 g/cm³ |

| Chemical Resistance | Excellent against most acids, alkalis, and solvents |

| Flexural Strength | >80 MPa |

| Thickness Range | 0.5 mm to 50 mm (Customizable) |

Manufacturing Process Flow

The production of Hezhen papermaking ceramics using mica powder calcined mica sheet insulation high temperature resistant material involves a meticulously controlled, multi-stage process to ensure superior material properties and dimensional accuracy. Our commitment to quality begins with the selection of raw materials and extends through every phase of manufacturing, adhering to stringent international standards such as ISO and ANSI for reliability and consistency.

Process Steps:

1. Material Sourcing & Calcination

High-purity natural mica is carefully sourced and then subjected to precise calcination at elevated temperatures. This thermal treatment removes volatile components, enhances the crystal structure, and improves the mica's thermal stability and dielectric properties. Ceramic binders and specialized additives are also prepared.

2. Mixing & Forming

The calcined mica powder is homogeneously blended with proprietary ceramic binders and additives. This optimized mixture is then formed into specific shapes or sheets using advanced techniques such as high-pressure dry pressing, slip casting, or extrusion, depending on the final product geometry and application requirements.

3. Sintering & Densification

The formed green bodies undergo a precise sintering process in high-temperature furnaces under controlled atmospheric conditions. This critical step promotes ceramic bonding, densification, and crystallographic transformation, imparting the material's final mechanical strength, thermal resistance, and insulation properties.

4. Precision Machining & Finishing

Post-sintering, advanced CNC machining and grinding techniques are employed to achieve the exact dimensional tolerances and surface finishes required by industrial specifications. This ensures perfect fit and optimal performance in complex assemblies, often eliminating the need for further post-processing by the client.

5. Quality Control & Testing

Every batch undergoes rigorous quality inspection and testing, including dimensional checks, thermal performance analysis, dielectric strength tests, and mechanical property verification. Adherence to ISO 9001 and other relevant industry standards (e.g., ASTM, DIN) ensures consistent product quality and an extended operational lifespan for the end-user.

This meticulous process guarantees that our ceramics provide exceptional service life and demonstrate significant advantages in typical application scenarios, such as superior energy saving capabilities due to effective thermal insulation and unparalleled corrosion resistance in harsh chemical environments.

Technical Advantages and Performance

The advanced engineering behind Hezhen papermaking ceramics using mica powder calcined mica sheet insulation high temperature resistant material provides a suite of critical technical advantages, making it an indispensable material for challenging industrial environments. Our material excels where traditional ceramics or polymers fail, offering a reliable solution for enhancing operational efficiency and safety.

- Exceptional High-Temperature Resistance: Capable of continuous operation up to 1200°C, our material maintains its structural integrity and insulating properties even under extreme thermal loads. This is crucial for applications in metallurgical furnaces, high-temperature processing equipment in petrochemicals, and the demanding drying sections of papermaking machines.

- Superior Electrical Insulation: With a dielectric strength exceeding 20 kV/mm, it provides outstanding electrical isolation, preventing short circuits and ensuring operational safety in high-voltage industrial machinery and components, protecting personnel and valuable assets.

- Excellent Thermal Insulation (Energy Saving): The low thermal conductivity of 0.2 – 0.5 W/(m·K) significantly reduces heat transfer. This translates directly into substantial energy savings by minimizing heat loss from furnaces, drying cylinders, and other heated processes, contributing to lower operational costs and a reduced carbon footprint.

- Chemical Stability & Corrosion Resistance: Engineered to withstand aggressive chemical environments, including exposure to most acids, alkalis, and industrial solvents. This property ensures longevity and reliability in chemical processing plants and papermaking facilities where corrosive agents are prevalent.

- High Mechanical Strength & Wear Resistance: Its robust ceramic matrix imparts high compressive and flexural strength, making it resilient against mechanical stresses, abrasion, and erosion. This durability is vital for components exposed to material flow or mechanical impact.

- Dimensional Stability Under Thermal Cycling: The material exhibits excellent dimensional stability, resisting warping or degradation even through repeated heating and cooling cycles. This ensures precise fit and consistent performance over extended periods, reducing the need for frequent replacements.

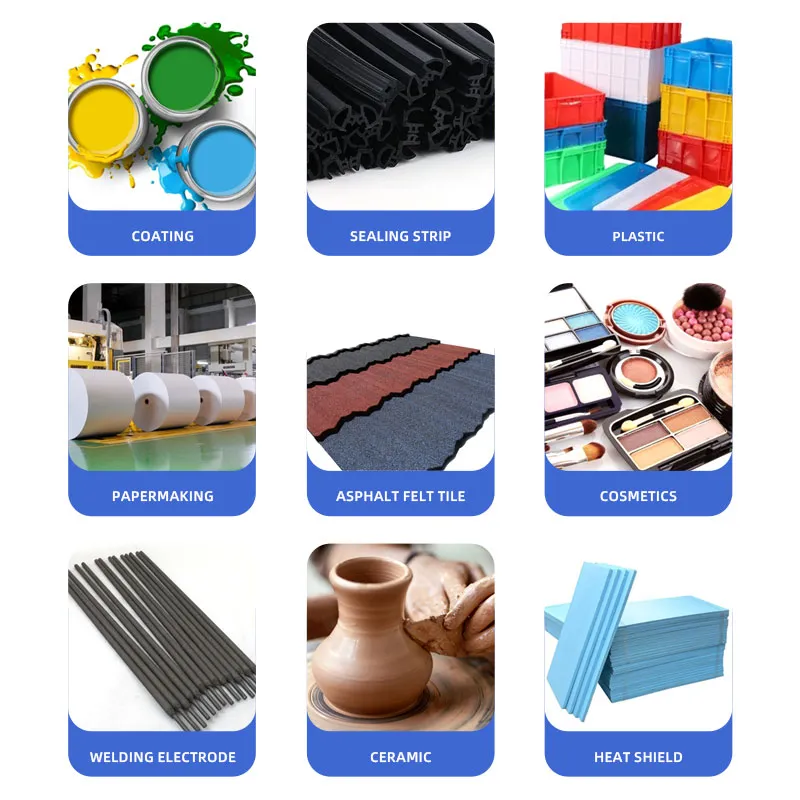

Application Scenarios and Target Industries

The versatility and superior performance of Hezhen papermaking ceramics using mica powder calcined mica sheet insulation high temperature resistant material make it invaluable across a spectrum of heavy industries. Its unique combination of properties addresses critical challenges in environments where heat, electricity, and corrosive agents converge.

- Papermaking Industry: Essential for components within the drying section, such as insulation for drying cylinders, press roll covers, and dewatering elements. Here, it offers energy savings by minimizing heat loss, extends equipment lifespan by resisting high temperatures and moisture, and enhances operational reliability in an environment rich with steam and chemical additives. Its resistance to wear also benefits dewatering foils and suction box covers.

- Metallurgy and Foundries: Used as thermal and electrical insulation in induction furnaces, electric arc furnaces, and holding furnaces. It forms critical liners, coil insulation, and structural components that endure extreme temperatures and molten metal splash, improving furnace efficiency and worker safety.

- Petrochemical Sector: Provides high-temperature insulation for cracking furnaces, reformers, and other processing equipment where high temperatures and corrosive gases are common. Its chemical resistance also makes it suitable for liners in tanks and pipelines handling aggressive media, reducing corrosion and extending asset life.

- Power Generation: Utilized as electrical insulators in high-voltage switchgear, bus bar supports, and thermal barriers in turbines and boilers. Its excellent dielectric strength and high-temperature resistance ensure reliable operation and safety in critical power infrastructure.

- Glass Manufacturing: Employed in furnace insulation and hot-end components where extreme heat and chemical stability are paramount for consistent glass quality and energy efficiency.

These applications demonstrate the material's capability to deliver measurable improvements in energy efficiency, component longevity, and overall operational safety, leading to significant reductions in maintenance and replacement costs across diverse industrial sectors.

Vendor Comparison: Hezhen vs. Alternatives

When evaluating high-performance insulation materials, it is critical to consider the long-term benefits and total cost of ownership. Hezhen papermaking ceramics using mica powder calcined mica sheet insulation high temperature resistant material stands out in a competitive market due to its superior engineering and consistent performance, offering distinct advantages over traditional and generic alternatives.

| Feature/Parameter | Hezhen Ceramic (Mica-based) | Generic Industrial Ceramic | Standard Mica Sheet (non-calcined) | Asbestos-based Insulation (Legacy) |

|---|---|---|---|---|

| Max. Operating Temperature | >1200°C | 800-1000°C | 500-800°C | ~500°C (Hazardous) |

| Dielectric Strength | Excellent (>20 kV/mm) | Good (15-20 kV/mm) | Moderate (10-15 kV/mm) | Good (but hazardous) |

| Thermal Conductivity | Very Low (0.2-0.5 W/mK) | Low (0.5-1.0 W/mK) | Medium (0.4-0.8 W/mK) | Low (but hazardous) |

| Chemical Resistance | Excellent | Good | Moderate | Good (but hazardous) |

| Customization Options | High (Full engineering support) | Medium (Limited shapes) | Low (Standard sheets) | N/A (Obsolete) |

| Expected Service Life | Long (10+ years) | Medium (5-8 years) | Medium (3-5 years) | Short/Medium (due to degradation) |

| Cost Efficiency (Long-term) | High (Reduced maintenance, energy savings) | Medium | Low | Very Low (Health & disposal costs) |

This comparison clearly illustrates Hezhen's commitment to delivering a high-value, high-performance material that not only meets but often exceeds the most stringent industrial requirements, providing a superior return on investment through extended operational life and enhanced system efficiency.

Customized Solutions and Engineering Support

Hezhen understands that industrial applications often require highly specific solutions. We offer comprehensive customization capabilities for our ceramic materials to precisely match unique operational requirements and geometries. Our engineering team collaborates closely with clients from concept to implementation, ensuring optimal integration and performance.

- Tailored Dimensions and Shapes: Whether you require complex geometries, specific thicknesses, or large-format sheets, our advanced manufacturing and CNC machining capabilities allow us to produce components that fit your exact specifications without compromise.

- Optimized Material Composition: While our standard formulation provides excellent properties, we can adjust the ceramic matrix and mica content to fine-tune characteristics such as thermal conductivity, dielectric strength, or specific chemical resistance for highly specialized applications.

- Prototyping and Batch Production: From rapid prototyping for testing and validation to high-volume batch production, Hezhen offers flexible manufacturing capabilities to support your project timelines and scale.

- Expert Technical Consultation: Our experienced engineers provide in-depth technical support, including material selection guidance, design optimization, and application-specific recommendations to ensure the maximum benefit from our materials.

This commitment to customized solutions ensures that our clients receive not just a product, but a perfectly engineered component that seamlessly integrates into their systems, enhancing performance and longevity.

Application Case Studies and Customer Experience

Our materials have consistently delivered tangible benefits and performance improvements across various demanding applications. These real-world successes underscore the reliability and effectiveness of our advanced ceramic solutions.

Case Study 1: Enhanced Drying Efficiency in a Pulp & Paper Mill

A major North American pulp and paper mill faced persistent challenges with heat loss and insulation degradation in their drying section, leading to high energy consumption and frequent maintenance. After implementing customized Hezhen papermaking ceramics using mica powder calcined mica sheet insulation high temperature resistant material for their drying cylinder insulation, the mill reported a remarkable 12% reduction in thermal energy consumption within the first year. Furthermore, the superior chemical and wear resistance of the material extended the lifespan of the insulation components from an average of 3 years to over 8 years, significantly reducing maintenance downtime and associated costs. The plant manager commented, "Hezhen's ceramic solution was a game-changer for our drying process. The energy savings alone justified the investment, and the increased uptime has been invaluable."

Case Study 2: Improved Safety and Performance in Induction Furnaces

A leading European steel foundry sought to improve the electrical insulation and thermal efficiency of their large induction furnaces. Traditional refractory linings struggled with dielectric breakdown and thermal cycling. By integrating Hezhen's calcined mica sheet insulation as part of their furnace lining and coil support structure, the foundry achieved a 15% increase in furnace operational efficiency due to minimized heat loss and enhanced electrical integrity. The dielectric performance of the Hezhen material proved far superior, drastically reducing the risk of arc flashes and improving worker safety. The engineering team noted, "The reliability of Hezhen's mica ceramic in our high-frequency induction environment has set a new standard for our operations. It's a critical factor in our safety protocols now."

Quality Assurance, Certifications, and Authoritativeness

Hezhen is committed to delivering products of the highest quality and reliability. Our dedication to excellence is substantiated by rigorous quality control protocols, adherence to international standards, and a track record built on decades of expertise in advanced material manufacturing.

- ISO 9001:2015 Certified: Our entire manufacturing process, from raw material procurement to final product inspection, operates under the stringent guidelines of ISO 9001:2015 Quality Management System, ensuring consistent quality and continuous improvement.

- Comprehensive In-house Testing: We operate a state-of-the-art laboratory equipped for a full spectrum of material characterization, including thermal gravimetric analysis (TGA), differential scanning calorimetry (DSC), dielectric breakdown testing, mechanical strength assessments (e.g., flexural, compressive), and precise dimensional metrology. All products undergo pre-shipment verification.

- Adherence to Industry Standards: Our materials and testing procedures conform to relevant international standards such as ASTM, DIN, and ANSI, providing verifiable data and performance metrics that industrial clients can trust.

- Trusted by Industry Leaders: With over 20 years of specialized experience in advanced ceramic materials, Hezhen has established itself as a trusted partner for leading companies across the papermaking, metallurgical, and power generation sectors globally. Our long-standing client relationships are a testament to our reliability and product quality.

Our robust quality assurance framework and authoritative certifications provide our clients with the confidence that they are investing in a product engineered for peak performance and enduring reliability.

Frequently Asked Questions (FAQ)

A: Our material is engineered for continuous operation at temperatures up to 1200°C, with intermittent exposure to even higher temperatures depending on specific formulations and application conditions.

A: While traditional refractories offer high-temperature resistance, our calcined mica-based ceramic provides superior thermal insulation (lower thermal conductivity) and exceptional electrical insulation properties, often enabling thinner cross-sections for similar thermal performance and enhanced electrical safety.

A: Yes, it exhibits excellent chemical stability and corrosion resistance against a wide range of acids, alkalis, and industrial solvents, making it highly suitable for petrochemical and chemical processing applications.

A: Lead times for custom orders vary depending on complexity and volume. Standard products typically ship within 2-4 weeks. For custom-engineered solutions, lead times are determined during the design and quotation phase, usually ranging from 6-12 weeks for initial prototyping and batch production. Please contact our sales team for precise estimates.

A: With proper installation and within specified operating parameters, our ceramic insulation materials are designed for an exceptionally long service life, typically exceeding 10 years in demanding industrial applications, significantly reducing the need for frequent replacements.

Ordering and Comprehensive Support

At Hezhen, our commitment extends beyond delivering superior materials; we provide comprehensive support throughout the entire customer journey, from initial inquiry to post-installation service.

- Lead Time & Fulfillment: We maintain efficient production schedules to meet client demands. Standard product orders are typically fulfilled within 2-4 weeks. For custom-engineered components, our team provides clear timelines during the quotation phase, ensuring transparency and predictability.

- Warranty Commitments: All Hezhen products are backed by a comprehensive warranty, guaranteeing against manufacturing defects and material failures under specified operating conditions. Details of our warranty policy are available upon request and are provided with every order.

- Dedicated Customer Support: Our expert sales and technical support teams are readily available to assist with product selection, technical specifications, application guidance, and troubleshooting. We offer responsive after-sales service to ensure continuous optimal performance of our materials in your operations.

- Global Logistics: We have established reliable logistics networks to ensure timely and secure delivery of our products to clients worldwide, managing all aspects of shipping and documentation.

Partner with Hezhen for not just advanced ceramic materials, but a complete solution supported by unparalleled expertise and customer-centric service.

References

- ASTM International. (2020). Standard Test Methods for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at Commercial Power Frequencies. ASTM D149.

- ISO. (2015). Quality management systems – Requirements. ISO 9001:2015.

- Kingery, W. D., Bowen, H. K., & Uhlmann, D. R. (1976). Introduction to Ceramics (2nd ed.). John Wiley & Sons.

- ASM International. (2001). Engineered Materials Handbook, Volume 4: Ceramics and Glasses. ASM International.

- International Energy Agency (IEA). (2022). Industrial Energy Efficiency Trends and Policies.